Manufacturing Support

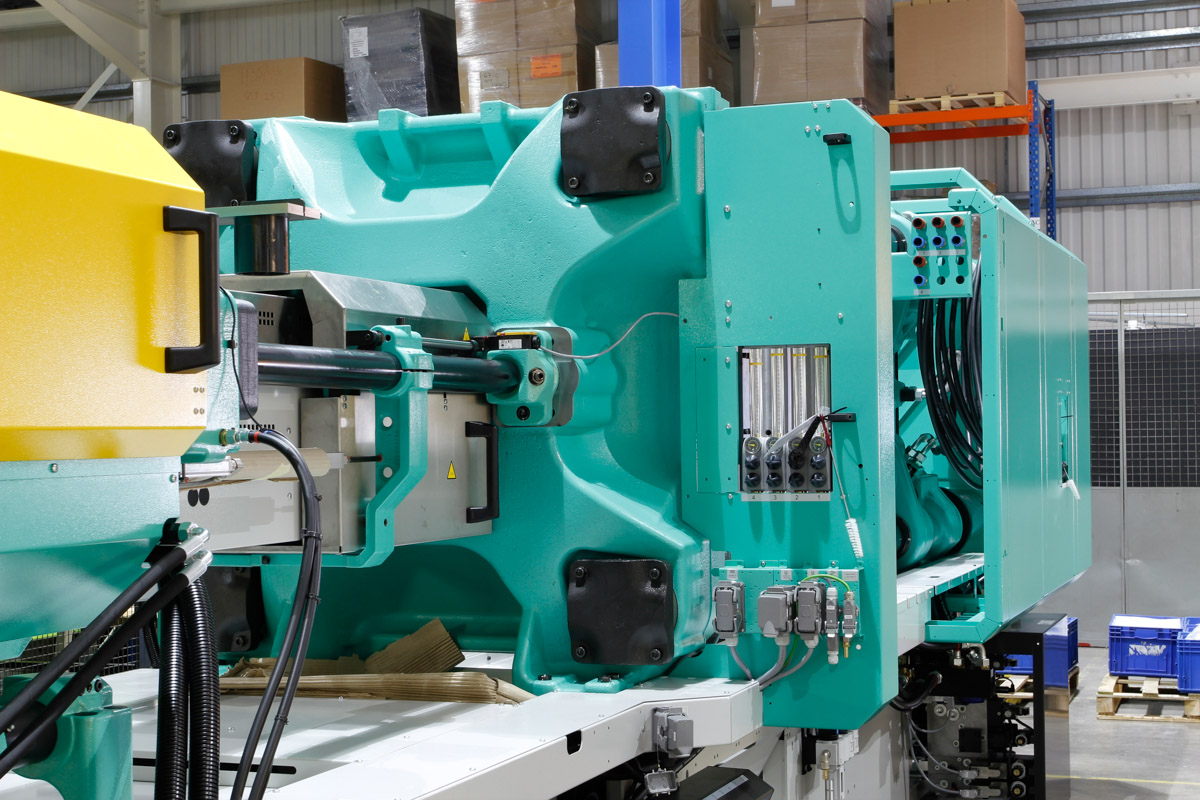

All the care and effort put forth in part design and material selection should not be forsaken as you prepare for manufacturing. The experts at The Madison Group understand molding, not just the mechanics of the equipment, but the fundamental process contributions to performance and quality of parts.

We have decades of engineering experience working with both stateside and offshore tool designers and molders. Let us put our knowledge to work for you by being your technical advocate in design for manufacturing (DFM), tool design reviews, Moldflow® simulation, and process reviews.

The Madison Group’s experience extends far beyond the molding processes. We support our customers in developing and troubleshooting assembly methods such as plastic welding, fastening, and other joining techniques. We apply our broad experience across diverse market fields to any product and application, providing unique solutions in a timely manner.

Avoid manufacturing issues for your plastic parts.

Find solutions to correct production problems.

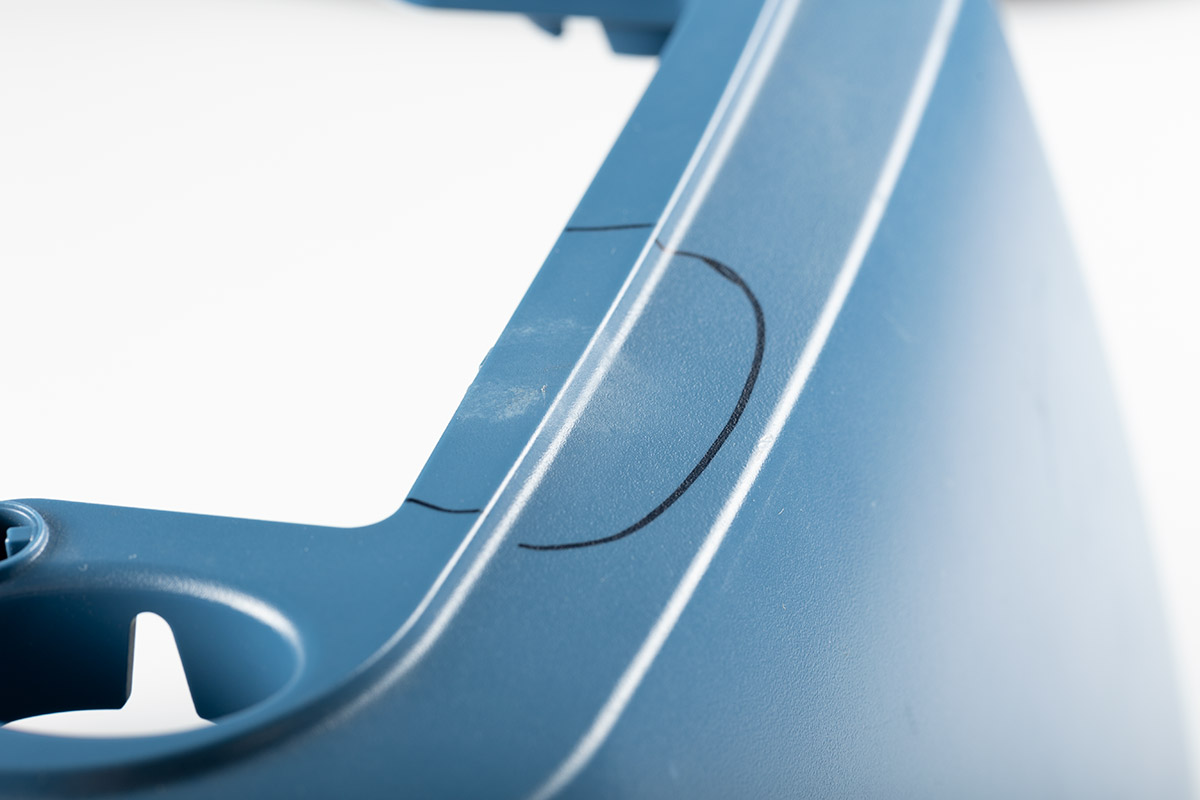

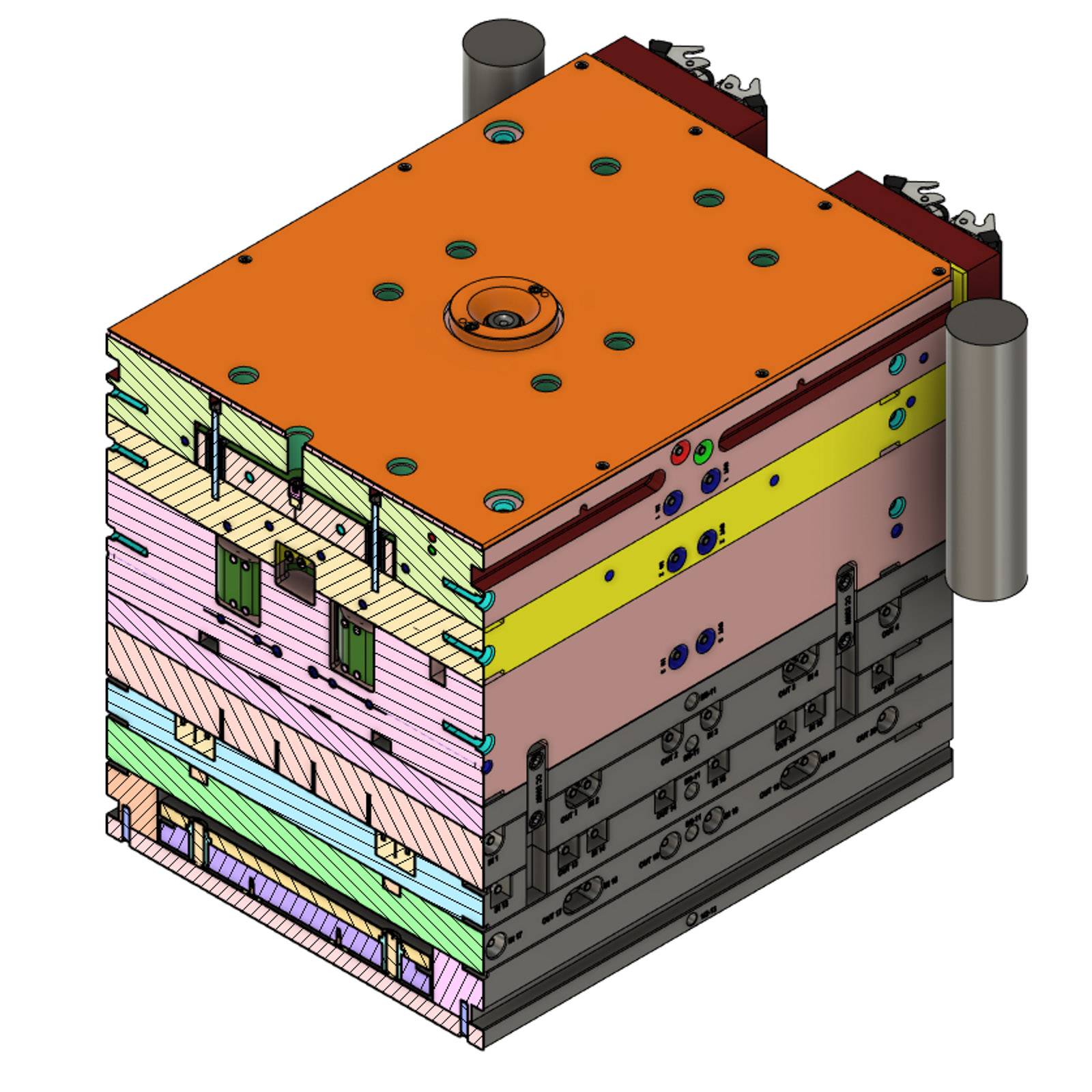

Housing requiring gate placement change to eliminate jetting.

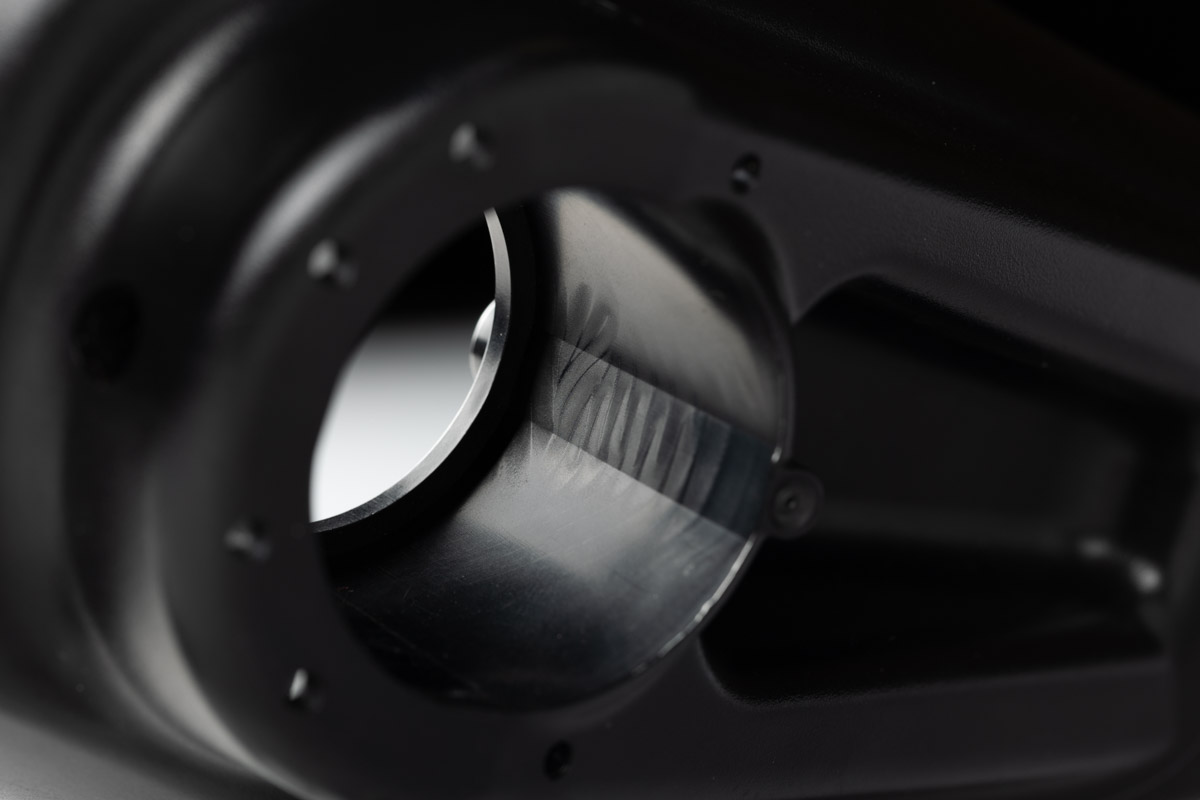

Interior of housing showing jetting defects eliminated with a change in gate type and placement.

On-Site Support

Whether you are an in-house molder or subcontract the manufacturing of your parts, The Madison Group can assist you. Our engineers’ knowledge of plastics and processing allow them to efficiently find data-driven solutions that boost your productivity, improve quality, and reduce scrap. We can also be your technical advocate when you are trying to validate your processes or implement tooling and processing changes that will yield improved part performance.

Molding troubleshooting and optimization requires a thorough understanding of processing behavior and of the corresponding materials response. We support our clients providing guidance into setting up proper DOE studies and selecting the correct testing that should be performed in order to verify the final part quality.

Common issues addressed during process evaluations:

- Material degradation

- Dimensional stability issues (shrinkage and warpage)

- Processing limitations

- Non-fill condition (short shot)

- Part brittleness

- Poor weld line performance

- Improperly designed feed systems

- Voids and porosity

- Cracking

- Curing

- Optical clarity

- Surface defects and imperfections (e.g. splay, jetting, sink, flash, gate vestige, drag lines, knit lines, texture/finish)

- Crystallinity

- Demolding issues

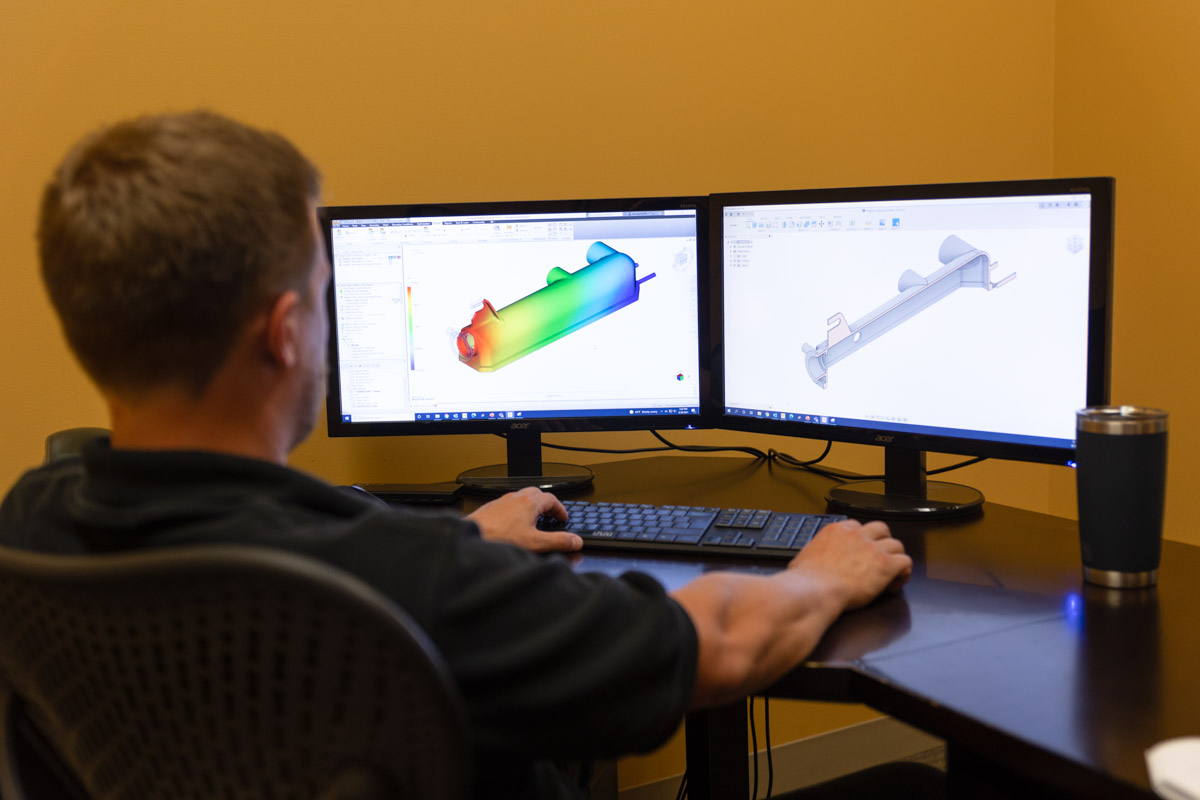

Moldflow Analysis

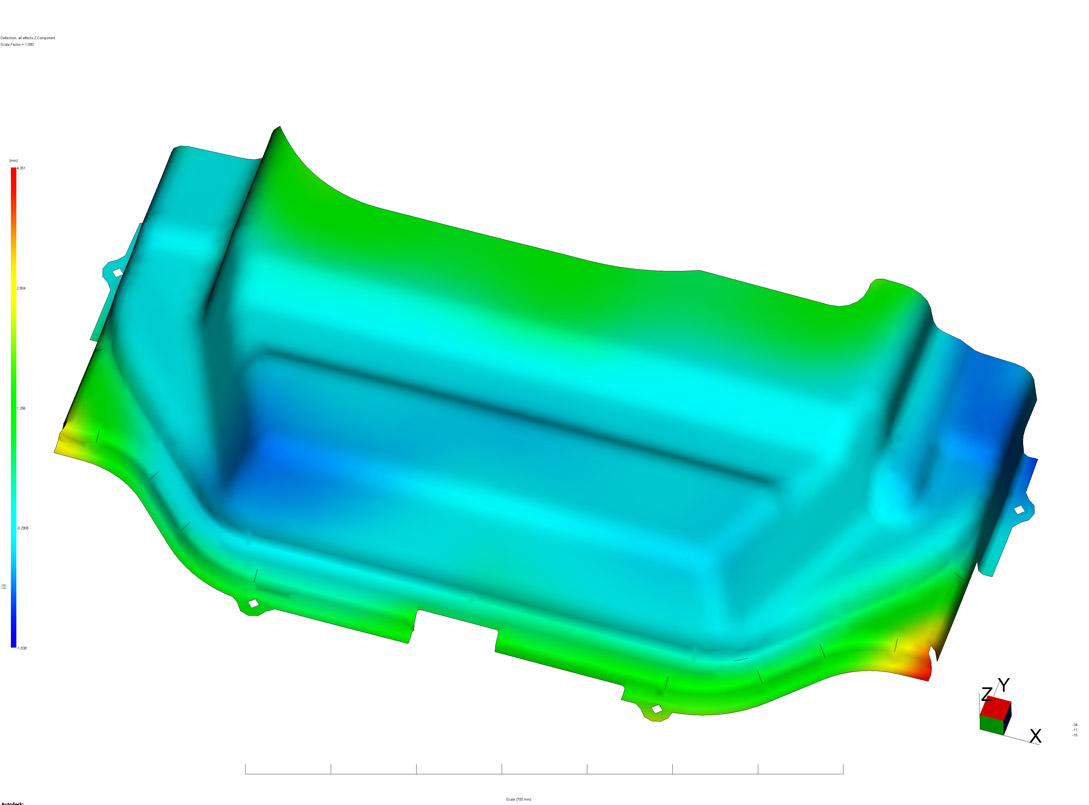

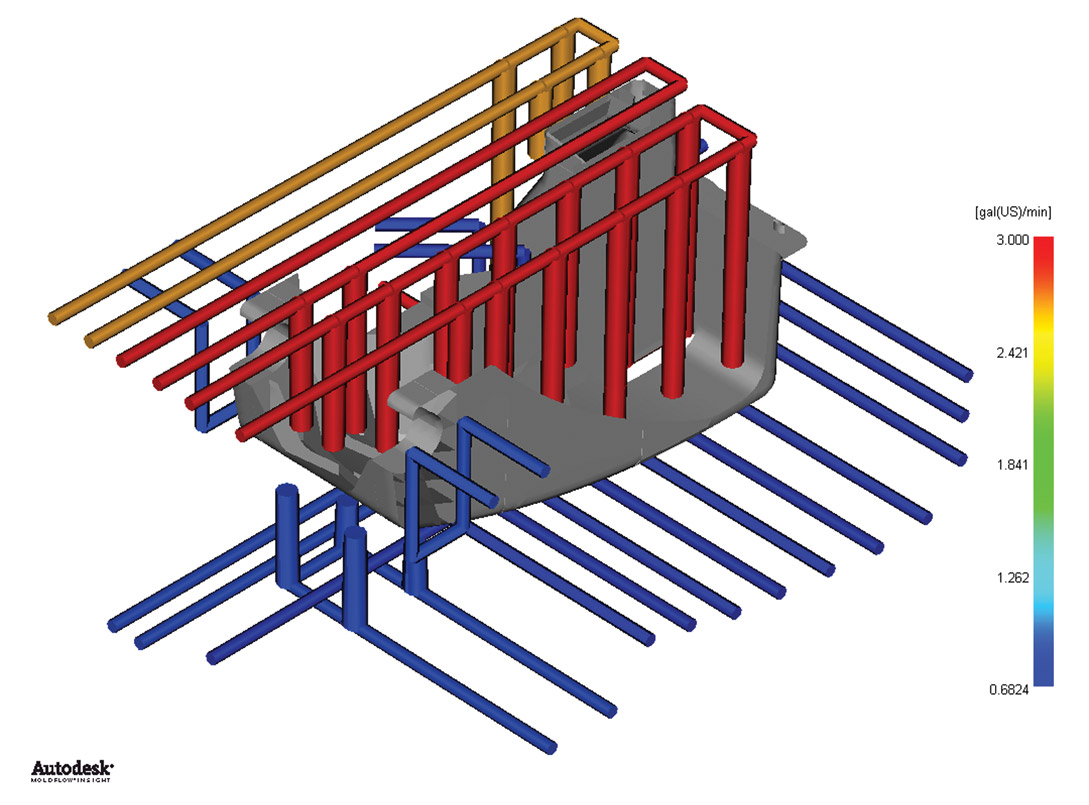

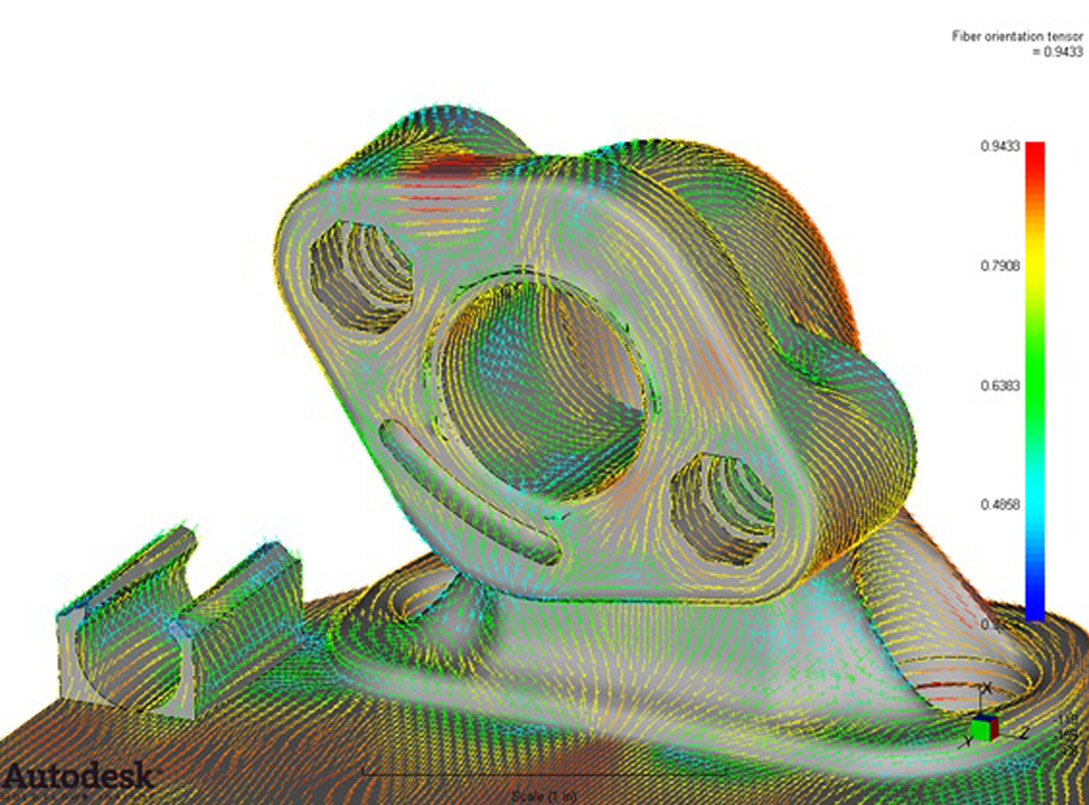

Good mold design and processing start with good part design. Poorly placed knit lines, excessive part warpage, high residual stresses, and inferior fiber orientation can quickly turn what appears to be a great design and material into an ultimate product failure. The Madison Group uses Moldflow® analysis to proactively ensure part and mold designs, as well as processing parameters, have been optimized for both part quality and cycle time. Consider our experience in simulation at the early stages of design and tool development. In addition, we can help troubleshoot your process to prevent or resolve manufacturing problems and reduce cost. With the help of simulation technology, we can ensure that the design and mold will work right the first time.

Our Moldflow® analysis can be scaled to fit your needs and can include:

- Gate location optimization

- Fill/pack analysis

- Warpage evaluation and reduction

- Cooling analysis

- Cycle time optimization

- Fiber orientation and weld line optimization

Moldflow Analysis Request

If you would like to have The Madison Group perform Moldflow analysis please fill the form linked to below.

Mold flow simulation.

Flow simulation.

Cooling analysis.

Fiber orientation.

The Madison Group’s expertise is not limited to processing of thermoplastics by way of injection molding. Our experts also have experience in more complex molding processes such as:

- Thermosets

- Over-molding

- 2-shot

- In-mold labeling

- Co-injection

- Gas-assist

- Injection-compression

- Compression molding

Inquire Today

At The Madison Group we are always ready to assist. Our engineers experience in mold design and manufacturing can save you time and effort, allowing you to make a better product, faster. Contact us today to learn more about our manufacturing and process support services.