As we seek sustainable solutions for the plastic materials we use every day, bioplastics have not established significant momentum. In fact, in 2019 bioplastics accounted for only one percent of plastic produced annually. The usage of bioplastics is more often connected to “greenvertising” or green marketing campaigns as companies try to address the environmental concerns of their consumers. A quick internet search on bioplastics can reveal an abundance of conflicting and often confusing information. This article hopes to arm the reader with accurate information on bioplastics and clear up the confusion caused in today’s media.

What Are Bioplastics?

First, let us define what we mean by bioplastics. Bioplastics are a diverse family of materials with a variety of properties and characteristics that can be further categorized into three main groups. The first group are plastics that incorporate content made from renewable biomass sources. These sources could include plant feedstocks such as corn, cassava, sugar beet, or sugar cane, to name only a few. It is important to note that this group can also include plastics that utilize a combination of content from both renewable plant feedstocks as well as conventional petrochemical feedstocks. In this group, there is no global standard for the minimum amount of renewable content required for a plastic to be labeled as a bioplastic. In Japan the industry-wide requirement is at least 25% renewable material, while in the U.S. this requirement can range anywhere from 7% to 95% depending on the product category. Manufacturers are encouraged to report their renewable biomass content on their bioplastic labels.

There is a popular perception that all bioplastics are biodegradable. Unfortunately, this is not the case. In fact, biodegradable bioplastics represented only approximately 55.5% of total bioplastics produced annually in 2019. Biodegradable plastics made from renewable biomass sources make-up the second group of bioplastics.

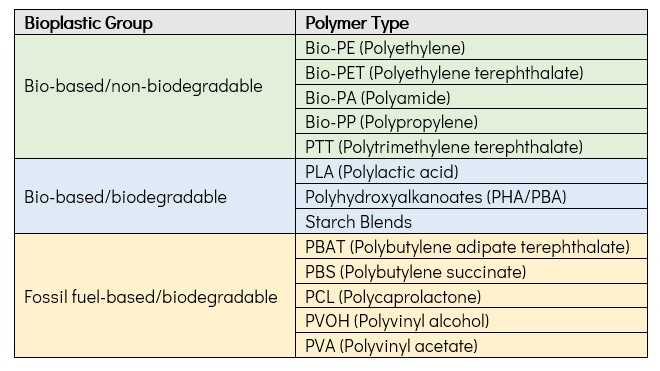

The third group of bioplastics are also biodegradable, but they are created from petrochemical feedstocks rather than renewable biomass sources. This last group seems incredibly counterintuitive and potentially misleading to consumers since it includes no renewable biomass content. A summary of the three groups of bioplastics, including polymer types typically included in these groups, can be found in Table 1.

Table 1. Classification of Polymer Type by Bioplastic Group

Why are Bioplastics Important?

There are numerous potential benefits associated with use of bioplastics. These benefits can include reducing fossil fuel usage; carbon footprint reduction; and/or reduced of global warming potential (GWP). Approximately, eight percent of the world’s oil is used to create plastics. The use of bioplastics produced from renewable biomass sources can aid in reducing dependence on fossil fuels. Fossil fuels represent a limited resource, and their prices are expected to rise as this resource continues to be depleted. Fossil fuels sources are highly concentrated in localized regions, while renewable plant feedstocks can be grown nearly all over the world.

Renewable plant feedstocks, such as the castor bean plant, absorb carbon dioxide during their growth. Therefore, using these castor bean plants to create bioplastics essentially, removes carbon dioxide from the earth’s atmosphere and keeps it stored throughout its entire product life, or even longer, if the product is recycled. Even if that carbon dioxide is released when the product decomposes it is simply returning the carbon that the plants absorbed while growing, instead of releasing new carbon that had previously been trapped in the ground as a fossil fuel. According to European Bioplastics, substituting the annual global demand for fossil-based polyethylene (PE) with bio-based PE would save more than 46 million tons of carbon dioxide.

Bioplastics that are biodegradable can reduce the volume of municipal waste that would need to be recycled or disposed of in a landfill. This would require that municipal facilities have composting capabilities as well as a market for their compost. The composting of biodegradable plastics through residential, neighborhood, or community efforts can further reduce the volume of municipal waste. This would require biodegradable plastics that can be processed at lower temperatures and humidity levels than that of industrial composters.

Additional Considerations

Before bioplastics are to be praised for their benefits, we must consider that their introduction does not come without drawbacks. These can include water pollution from the fertilizers and pesticides used in growing the crops, deforestation in order to increase crop acreage, and/or displacement of crops used for food production. Some research also suggests that bioplastics may incidentally encourage littering because consumers may believe that they will dissolve in nature.

The specific benefits of each unique bioplastic needs to be evaluated through a lifecycle assessment in order to measure the environmental benefits and burdens. Such an assessment covers all stages in a product’s life, as products may have very different environmental impacts during the different single stages of their life. A challenge of these assessments is that they do not consider the untapped potential of new, innovative products. One thing that is clear, there is an abundance of opportunities for biodegradable plastics and plastics made from renewable biomass sources to diversify the plastics which consumers use every day.