This article originally appeared in Plastics Engineering Magazine – April 2017

A variety of factors can contribute to or cause part failure, but understanding the causes can minimize the risks.

Material failures have an overall economic cost of billions of dollars annually, and can have a devastating effect on a product or even an entire company. While the precise definition of failure can be somewhat elusive, a good working description is “a component or process that is not working the way it was intended.” Failure is not always catastrophic, but it can be detrimental and have wide-reaching negative implications.

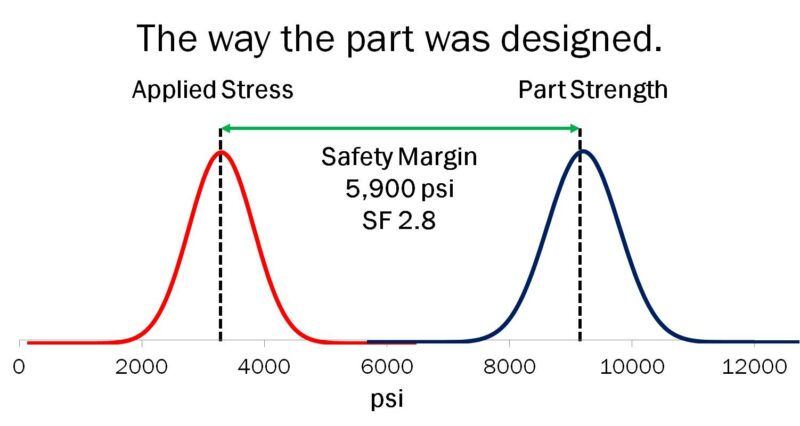

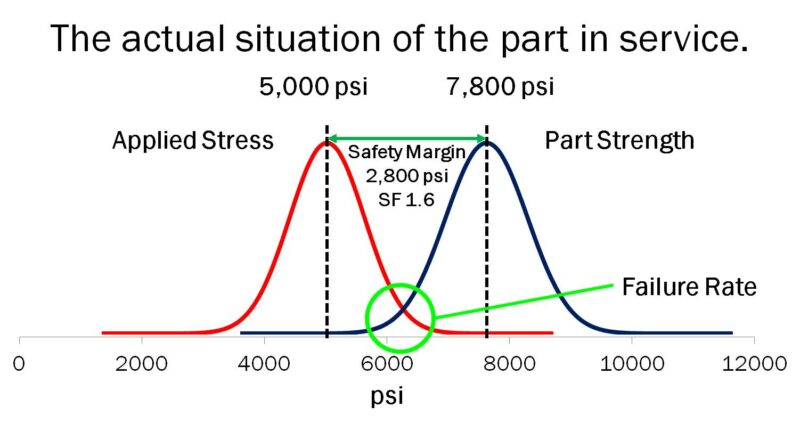

Certainly, manufacturers attempt to avoid failure, but often unanticipated factors result in unexpected problems. The chances for a successful application can be significantly increased through preventative measures, including appropriate material selection, proper mold design and process development through simulation, chemical compatibility screening, environmental testing, and a variety of mechanical evaluations. Failure, regardless of the type, occurs when a portion of the stress distribution exceeds the lower tail of the strength attribution. In many cases, a relatively large safety margin is thought to be in place. However, unanticipated factors produce a shift of either the stress or strain distributions that results in premature, unexpected failure.

Schematic representation of the anticipated safety margin and the actual overlap of applied stress and part strength of the product while in service. The change is often due to unanticipated factors that result in failure.

Multiple factors affect the performance of plastic components, including material, design, processing, installation, and service conditions. These factors do not act independently, and in most cases failure within plastic components is associated with multiple causes. This article addresses five of the most common contributing causes of plastic part failure, in the author’s experience.

- Ignoring the Effects of Time

- Chemical Contact in Service

- Molecular Degradation

- Impact Loading

- Designs with Sharp Corners