Non-Destructive Testing of Common Failures

A typical engineering analysis for a subrogation project starts with a visual non-destructive analysis that helps our customer decide the next step. If the project justifies additional analysis, we have the capability to further investigate with more advanced non-destructive techniques or with the use of destructive examinations and material testing. Our extensive knowledge of plastic materials allows us to determine how the failure occurred and who is the most responsible party.

The Madison Group is not limited to understanding the product engineering and materials, but also the environment, the end use, the installation and life history of the product. Our engineering subrogation services also include product brand identification and forensic engineering.

To ship samples for testing, please download the shipping form below.

We recommend using a carrier that properly tracks shipments. If you need help or have questions, call us at 608-231-1907.

Common Failure Tests We Routinely Perform

At The Madison Group we have the ability to analyze any plastic or polymeric product. As experts in the industry, we have the knowledge in materials, manufacturing, and design that can be applied to any investigation. Some examples of products that we commonly see requiring a subrogation failure investigation include:

- Water filters

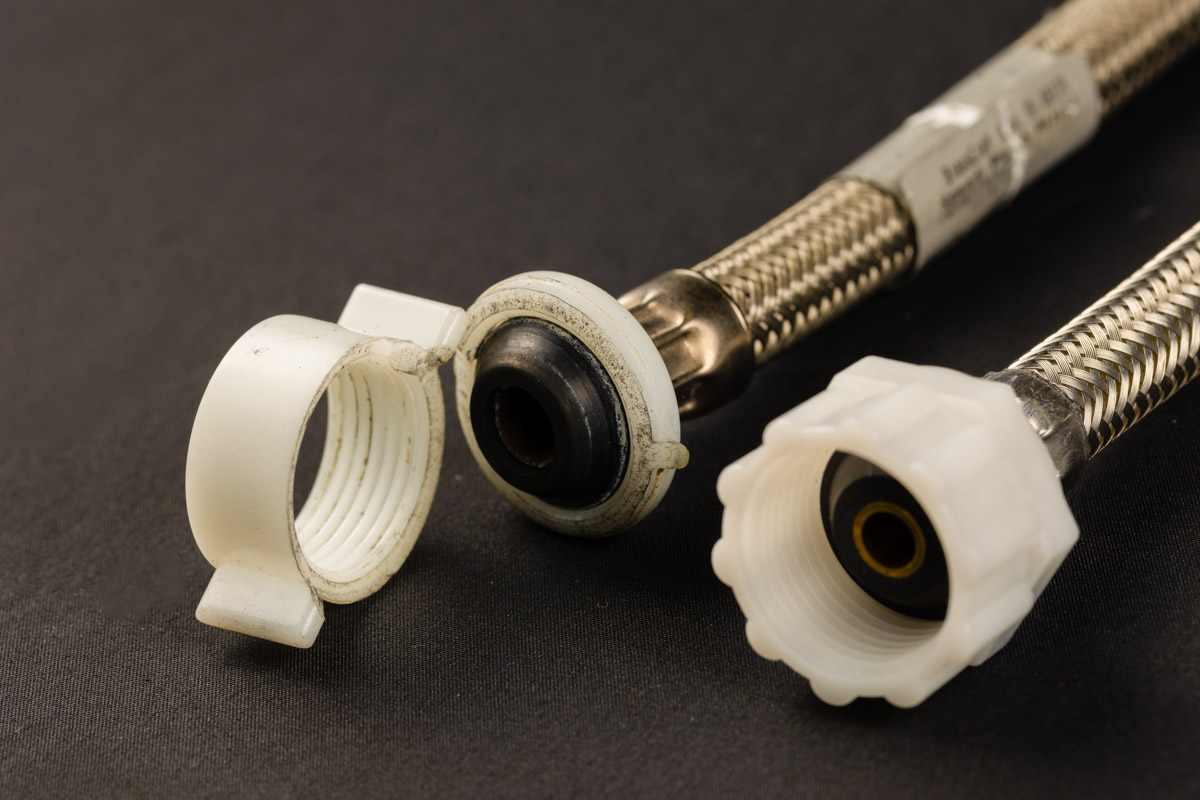

- Toilet supply lines, ballcocks, fill valves, floats and flappers

- Refrigerator fittings, valves, tubing, and housings

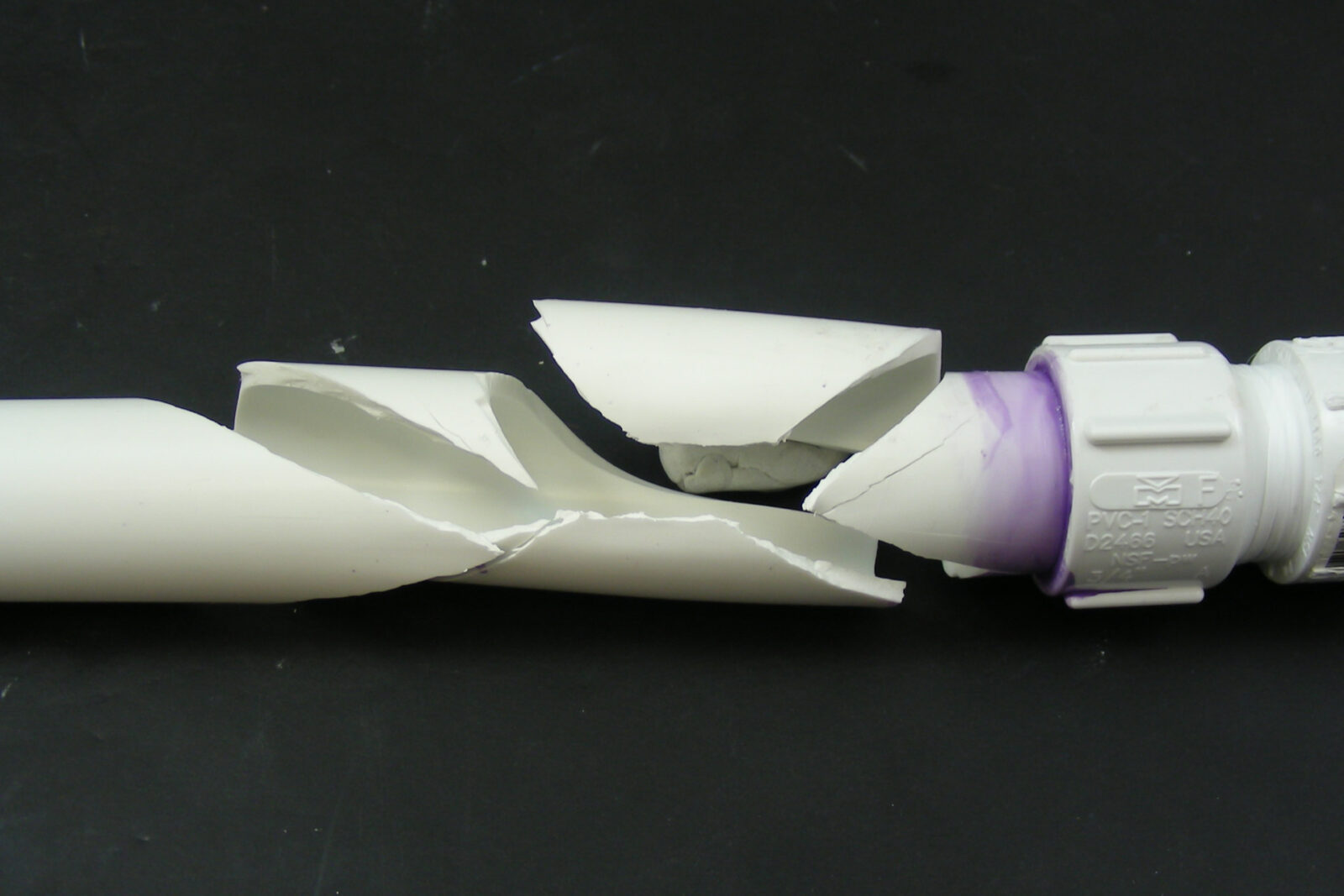

- PVC and CPVC pipes

- Fire sprinkler system components

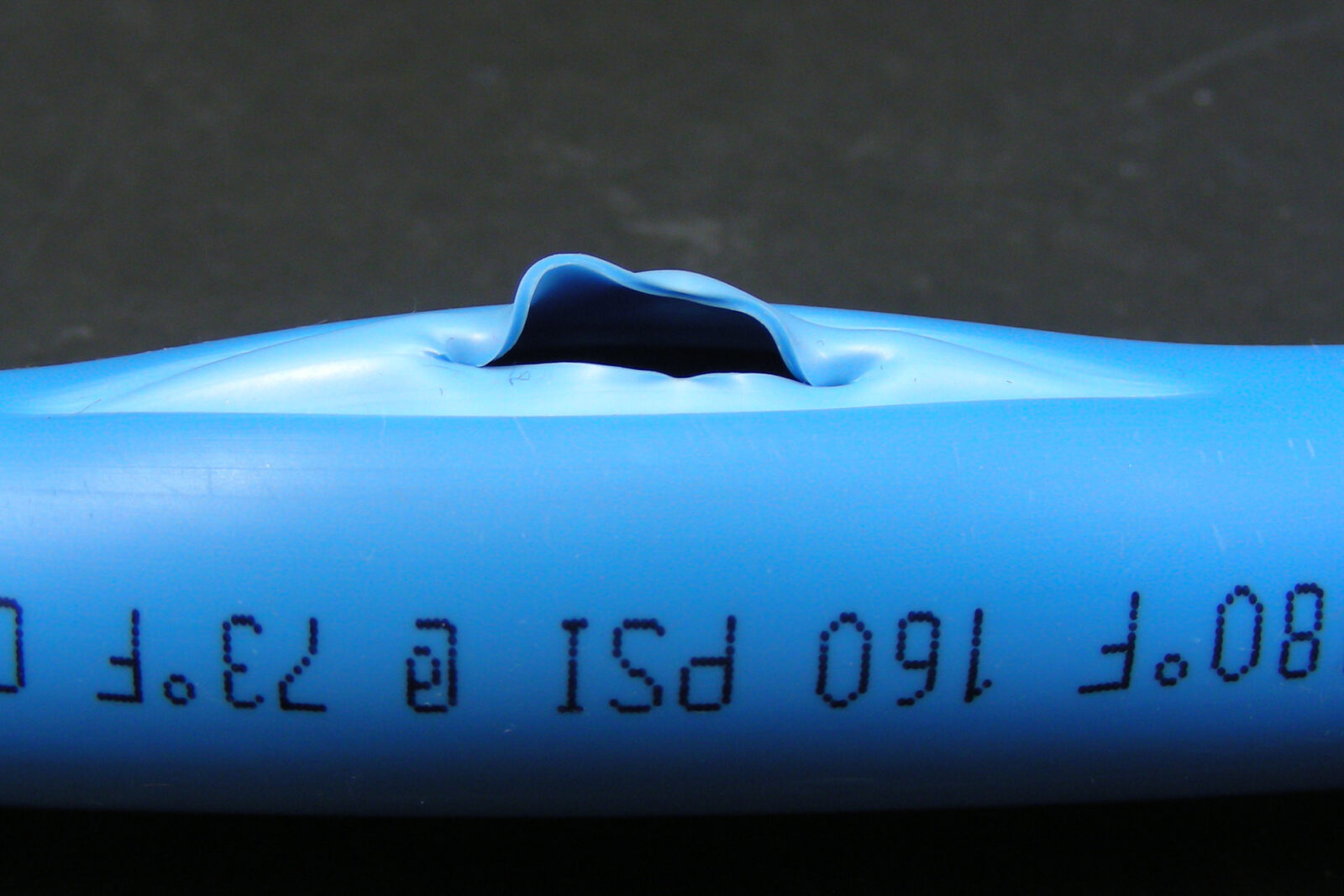

- PEX pipes and tubing

- Dishwasher valves and pump housings

- Flexible hoses and tubing

- Plastic fittings, couplings nuts

- Washer and dryer housings, valves, hoses, and fittings

- Steel braided hoses

”"We at MetLife Auto & Home consider The Madison Group (TMG) to be an invaluable resource. Prior to being introduced to your firm, we had a huge void in the area of investigating plastics failures. Not only has TMG been a cost effective alternative to the other generalized engineering firms we had been using, but my experience has been that the manufacturers we are subrogating against hold your conclusions in high esteem. Regardless where a plastics-related loss happens in the country, my first call is always to TMG."

Mark HagenSr. Subrogation Analyst, MetLife Auto & Home

Non-Destructive Testing

The first step in a subrogation engineering analysis typically involves a non-destructive visual inspection of the failed product or parts. The goal is to obtain as much valuable information as possible without significantly disturbing the current state of the evidence. We know that many subrogation failures may involve smaller claims. Therefore, our engineering services provide a comprehensive analysis and report for a reasonable cost that typically includes:

- Product identification

- Detailed visual analysis of failures

- Analysis of function and operation of parts

- Design analysis

- Pressure testing

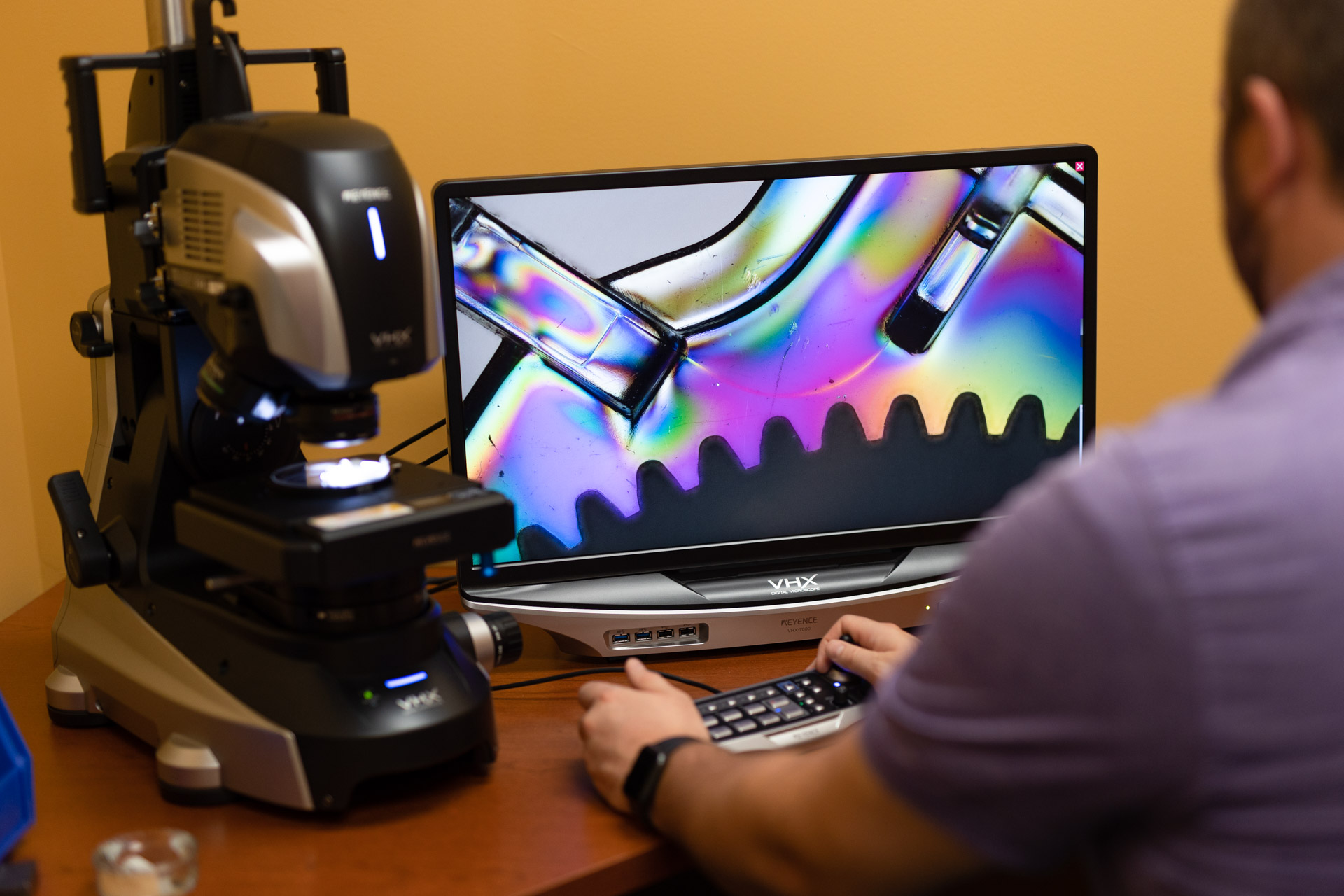

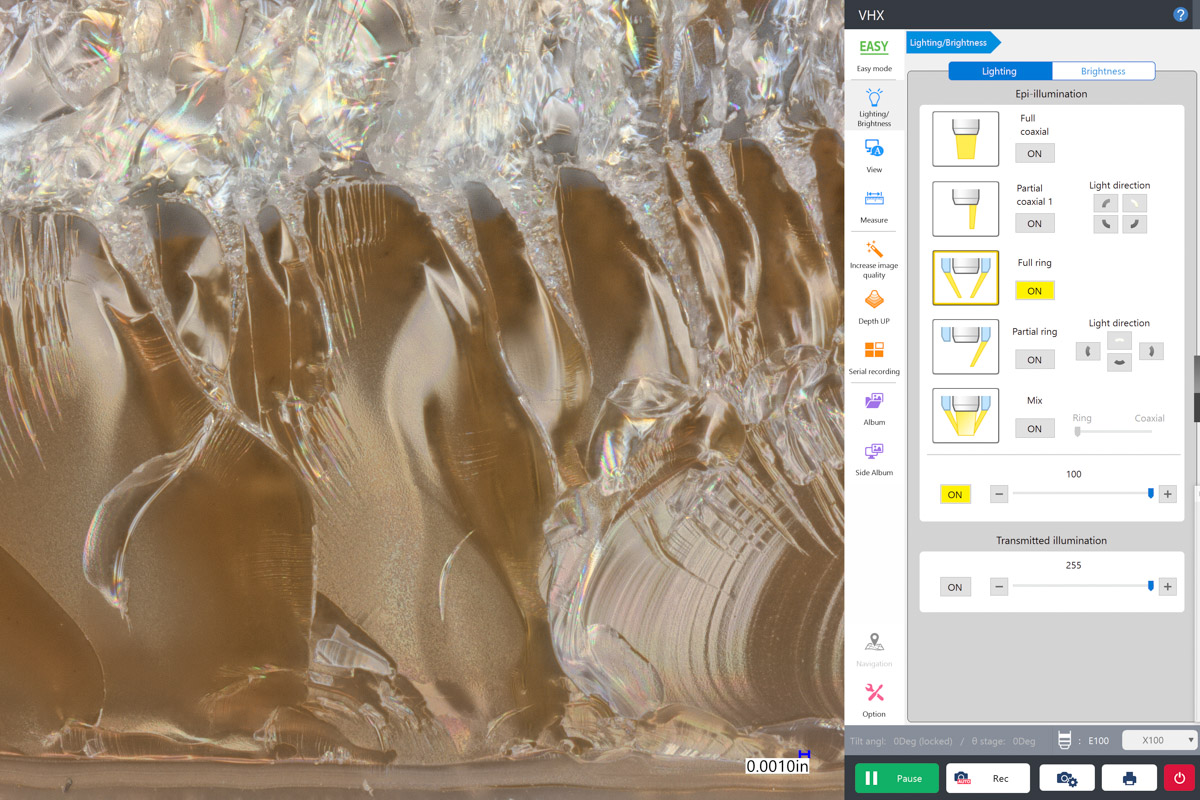

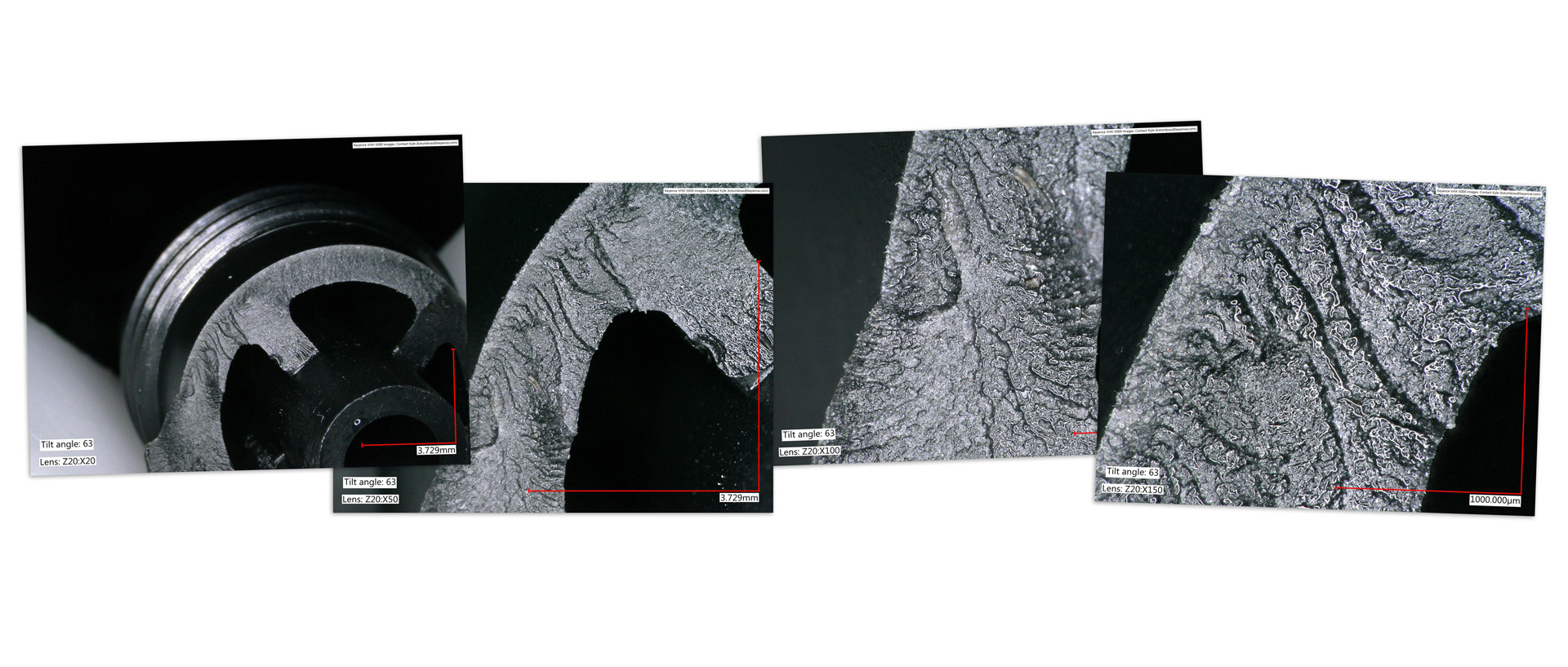

- Optical and digital low-magnification microscopy

- Color photographs and micrographs

- Analysis of exemplars

- Written reports (verbal when requested)

- Shipping of parts back to customer

- Storage while parts are being analyzed

- Technical support

Advanced Testing (Non-Destructive And Destructive)

For cases that require a more in-depth testing or additional destructive analysis, we can provide:

- Rebuttals to adverse party opinions and denial letters

- Low and high magnification microscopy (Digital Microscopy and SEM)

- Computer modeling and simulation analysis (Finite Element Analysis – FEA)

- CT-Scanning and X-ray inspections

- Sectioning, cutting and disassembling of evidence or exemplars

- Function, manufacturing, design, and assembly analysis

- Material, analytical and mechanical testing

- Expert witness and litigation support

Various Examples of Subrogation Water Line Failure Tests

Our Specialty Is Plastic

At The Madison Group we specialize in plastics. We devote all our resources to understanding the intricacies and subtleties of plastics. Our staff has years of experience in plastics failure analysis and expert consulting allowing us to provide answers and describe them in simple terms that can be easily understood by the non-engineer.

Our experience shows that plastic failures are typically due to a combination of factors rather than a change in one unique parameter. Our expertise in design and processing of plastic products enables us to understand why plastic parts underperform, malfunction and fail.

Inquire Today

We understand that polymer products can undergo complex failures. We are here to provide a unique service to the subrogation industry filling the gap of polymeric materials analysis and forensic engineering. Contact us today to learn more about our subrogation services.

If you would like to send us a part for analysis please download the shipping form below.