Design Review

Designing a part that is robust, functional, and manufacturable can be a challenge. Part designs for polymeric materials can be even more difficult given the time and temperature behavior dependencies of these materials as well as their sensitivities to environmental factors including, chemicals, humidity, and ultraviolet light. We offer extensive design review services as the staff at The Madison Group has a broad and deep understanding of the most important aspects of design required to ensure part success. Our team has the capabilities and tools to predict how easily a design can be manufactured, its robustness, how it will respond during assembly, while in service, and how it will perform over its lifetime.

The scope of our design reviews can be uniquely tailored to meet the needs of our clients and may include:

- Material review and characterization

- Part geometry optimization

- Stress calculations

- Structural analysis (FEA)

- Design for manufacturing and assembly (DFM, DFMA)

- Assembly Method Optimization/Evaluation

- Dimensional Analysis

- Cost Reduction

- Metal-to-Plastic Conversion

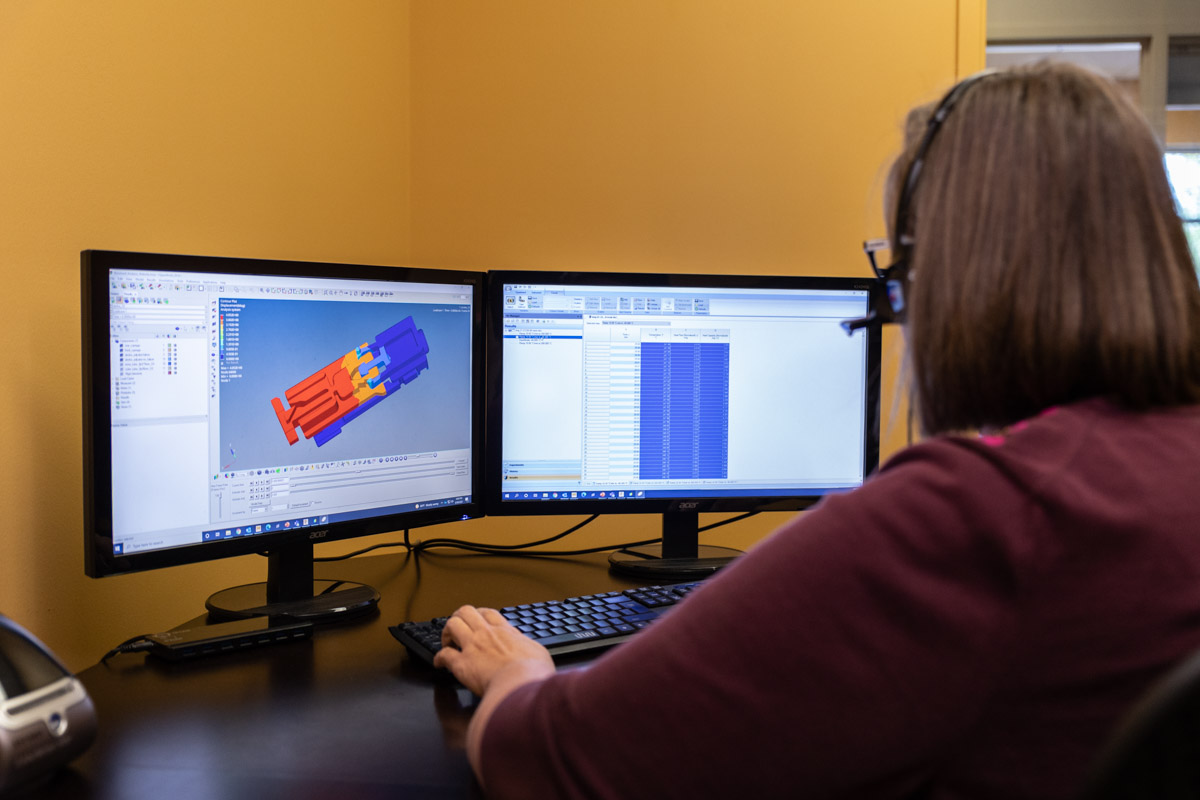

Structural Analysis (FEA)

As plastics are being used in more demanding applications every day, one of the best tools for predicting their success is structural finite element analysis (FEA). The Madison Group uses this tool to determine part and assembly performance including the following:

- Effect of temperature on stress and displacement within a part

- Resulting deflection and stress from pressure and mechanical loads on proposed design surfaces

- Impact of forces on a part over an extended period of time (creep)

- Consequence of fiber reinforcement on material property anisotropy with resulting stress and displacement within a part

- Influence of weld lines

The full evaluation of a design before production is a crucial step in the development of any product. This will avoid costly manufacturing problems, or worse, failures during intended use.

Inquire Today

At The Madison Group we are always ready to provide support in any of the product development stages you may be. Whether you are developing a new product, improving an existing one, or solving a problem, we have the experience needed to optimize a design for success. Contact us today and request information that will help you finalize your design faster and more effectively.