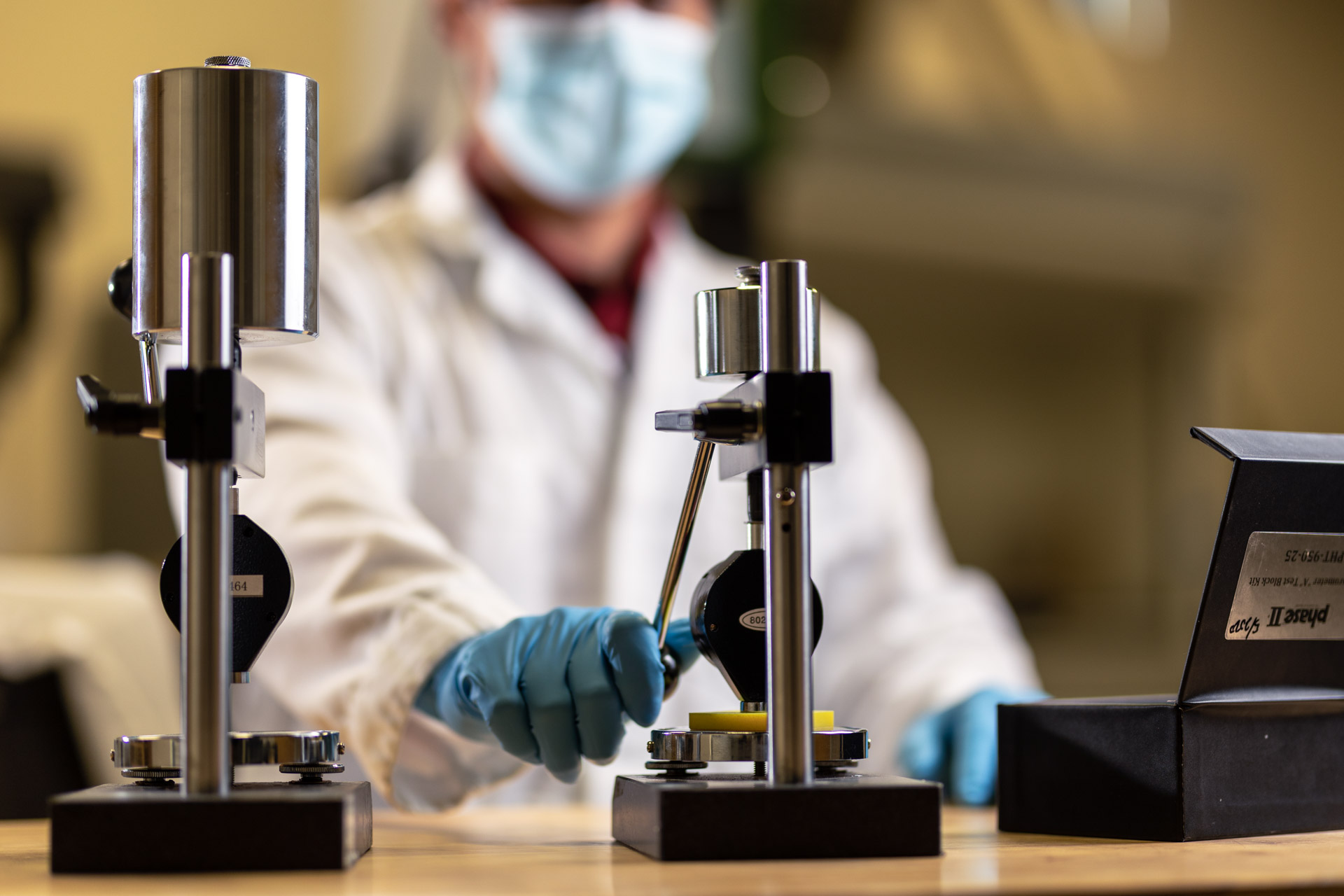

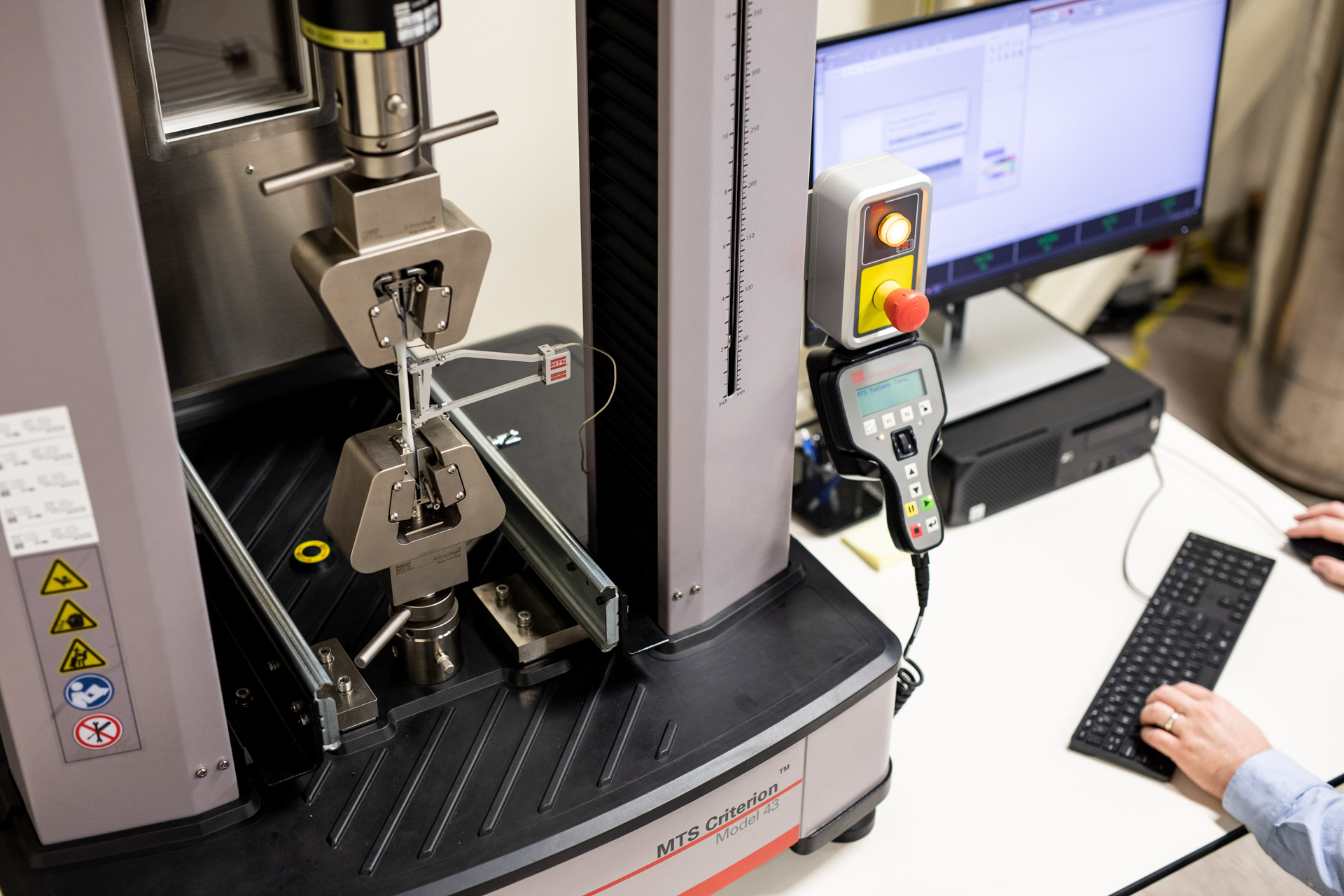

Material Testing

Are you making a new product and trying to qualify and compare different material options?

Have you received a material lot that is showing different processing behavior compared to previous lots?

Have you observed a residue or contamination in a part or assembly?

Or are you experiencing a product failure and are suspect of the material quality?

These are just some examples of where material testing can help. Material tests can be a powerful tool for analyzing suspect samples, verifying quality, comparing datasheet properties, and deformulating materials. While the list is extensive, some of the properties and variables that can be evaluated through material tests include:

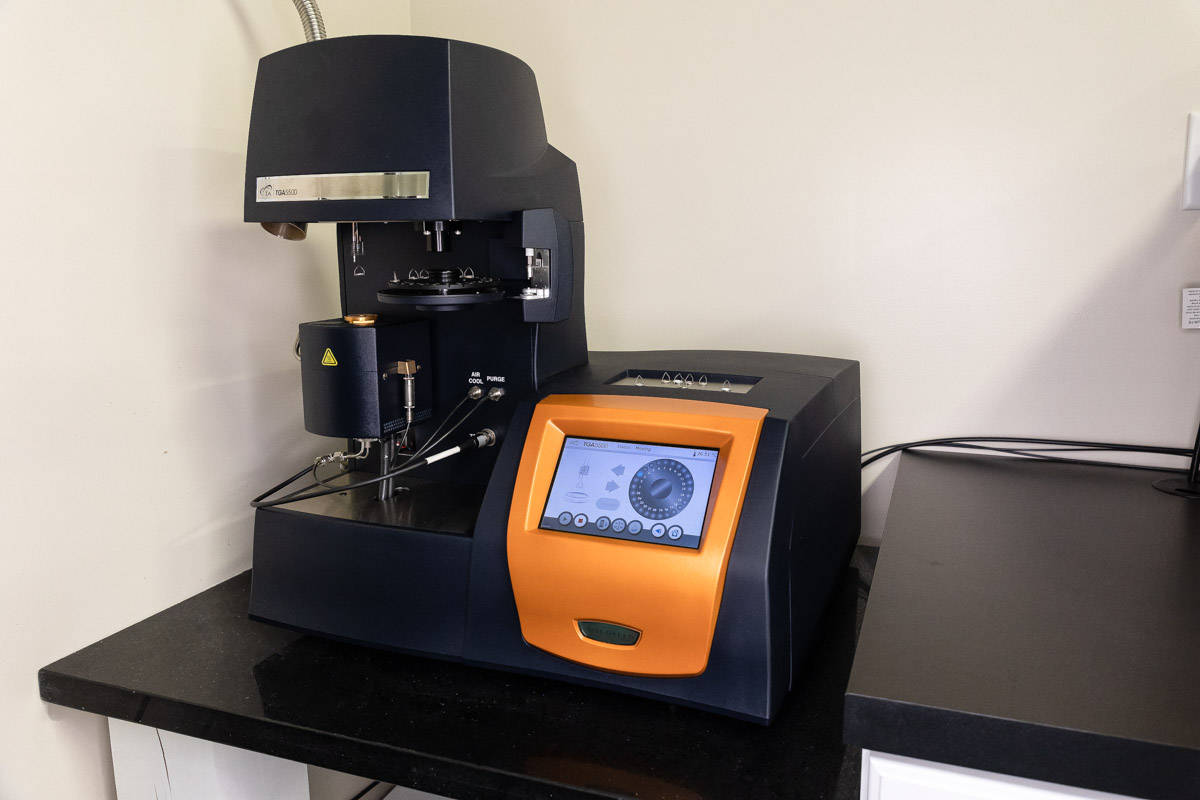

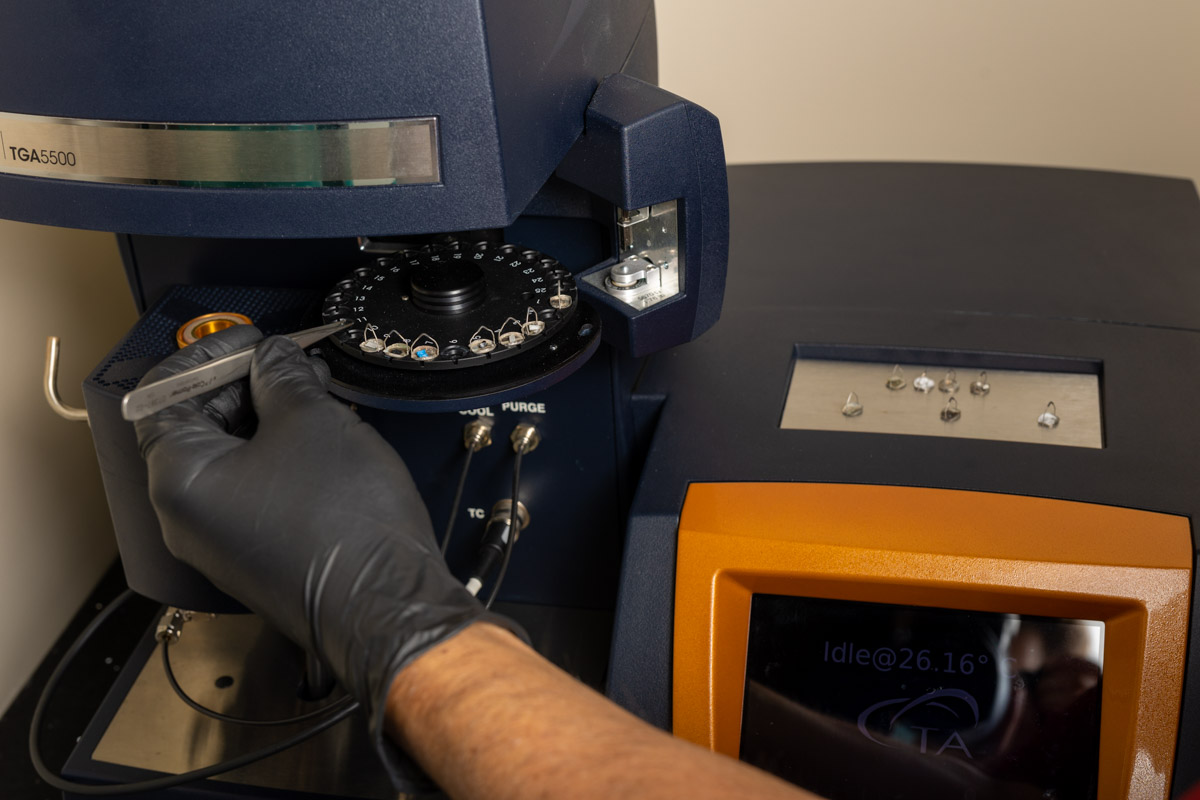

- Thermal behavior

- Density

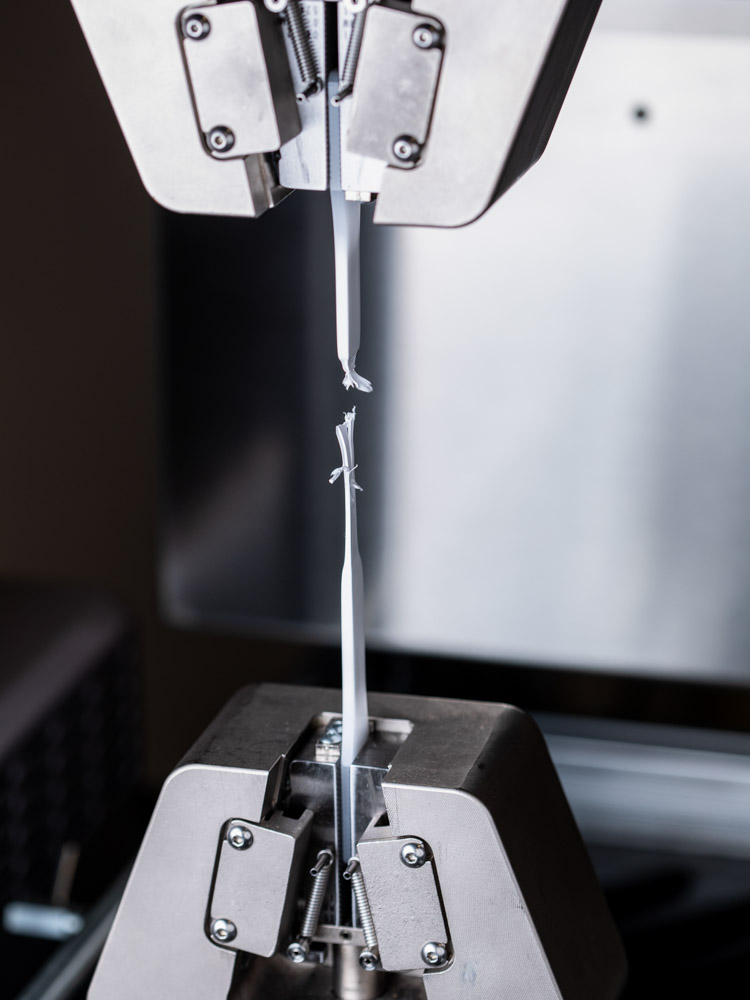

- Mechanical properties

- Thermomechanical response

- Electrical properties

- Molecular weight and structure

- Crystallinity

- Polymer chemical composition

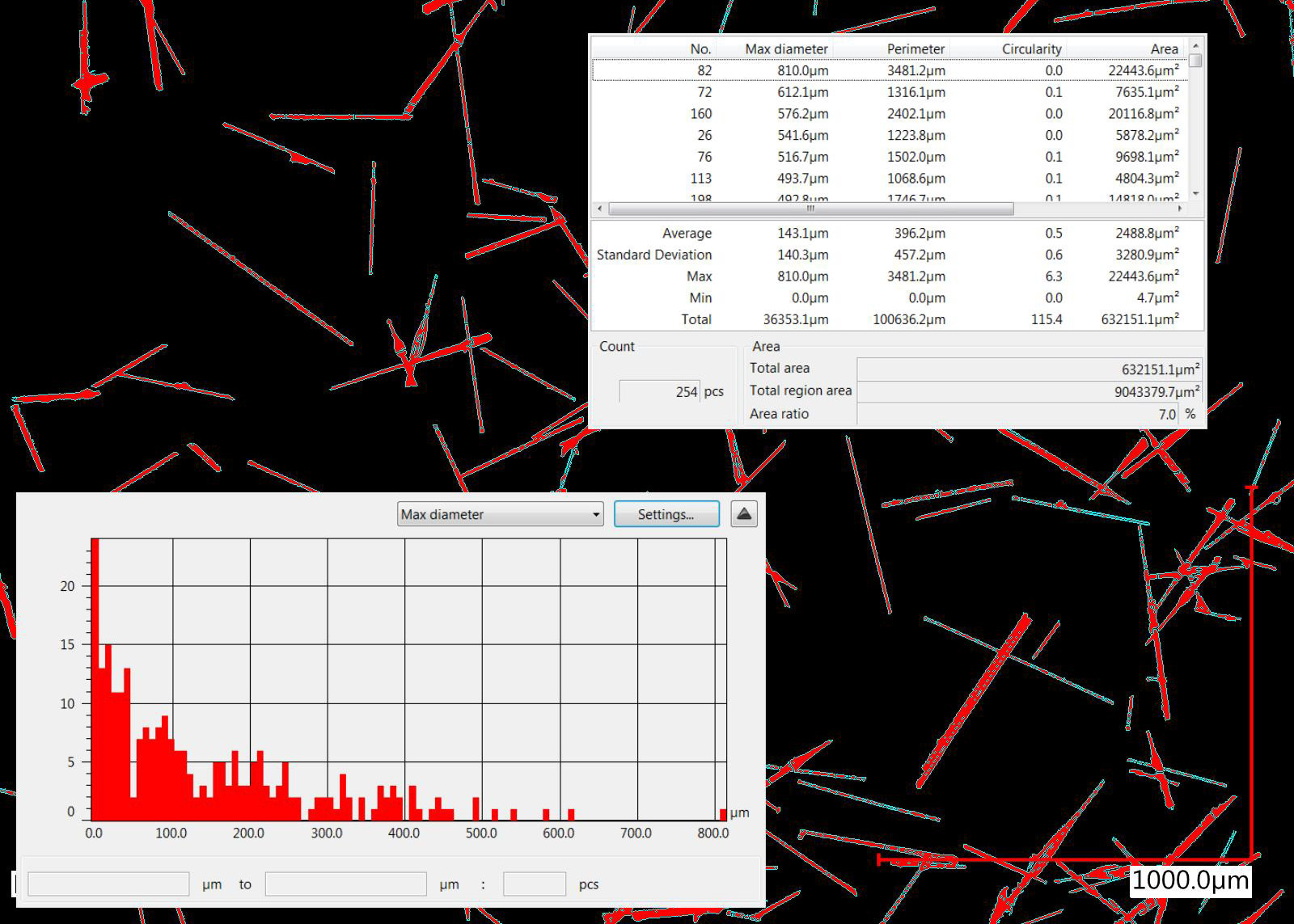

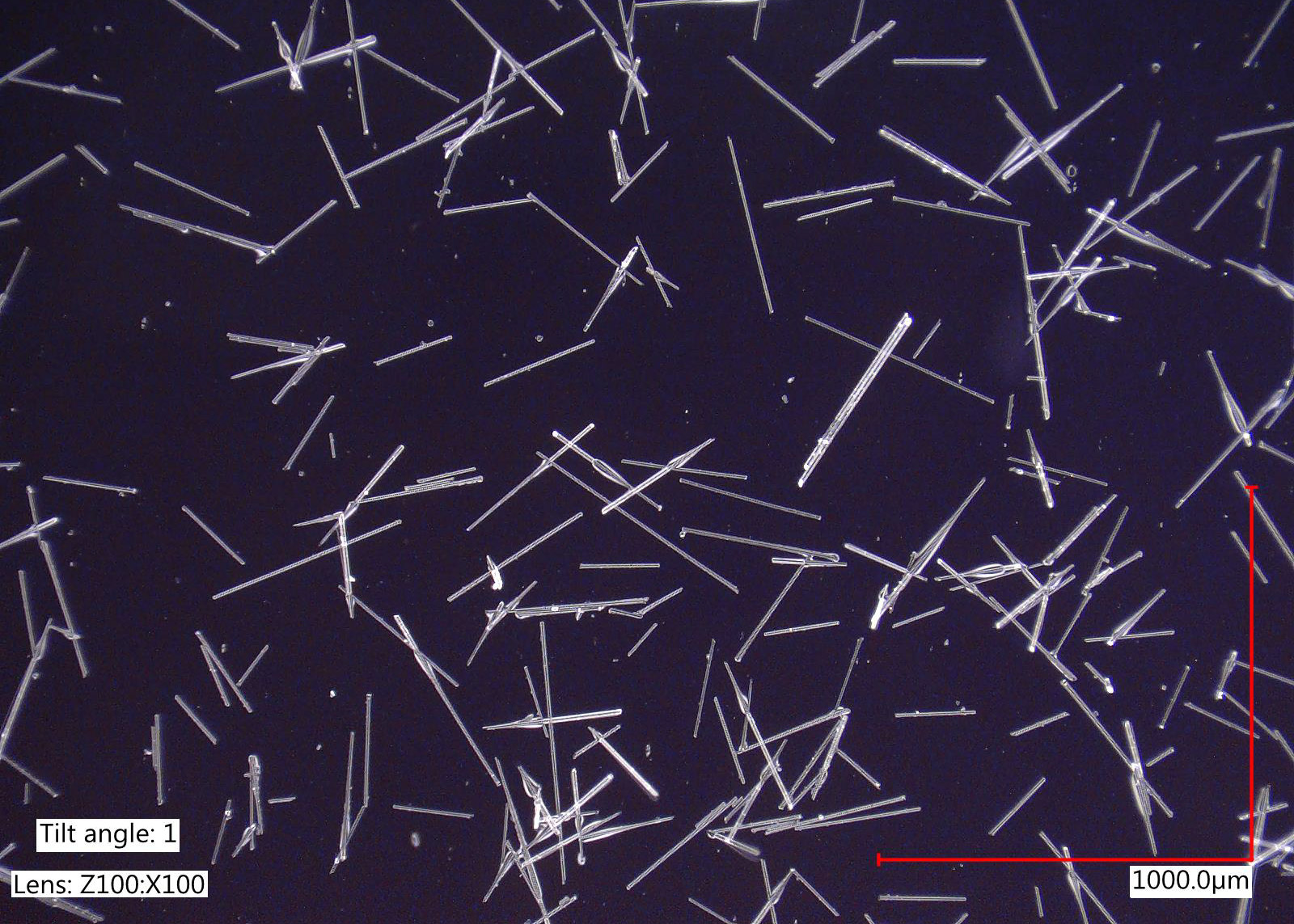

- Additive, filler, and reinforcement evaluation

- Flammability

- Thermal, UV and environmental resistance

- Chemical compatibility

- Moisture absorption

Experience is key when selecting the right tests that will provide the information needed to make critical decisions. When any type of material testing is considered, it is important to keep in mind its benefits, limitations, and the end goal.

The success of your product depends on a correct selection of materials. Have us test your material choices in order to maximize your rate of success. That is the purpose of material testing.

With decades of experience, The Madison Group possesses the necessary knowledge to select the correct test methods to achieve the desired end-goal. Just as important, we have experienced engineers that can interpret the data correctly. Test data can be useless without proper interpretation. Our general approach to material testing is to select the most logical set of test procedures balancing costs, turnaround time, extent of the data, and specificity towards the project needs. We collectively analyze all data in a manner that guides the analysis and opinions. This increases the degree of certainty and probability that the conclusions are correct and complete.

Our philosophy is not to provide you with a test, but with a solution. Our engineering team is able and experienced in numerous standard and custom testing methods necessary for analyzing plastics and other polymeric materials.

The success of any product design is largely based on a combination of good engineering and material choice. At The Madison Group we can thoroughly test your material choices in order to allow you to make a sound decision in your final plastic material selection.

Looking to deformulate or better understand a competitor material? We can help.

The Madison Group can help you achieve a successful product launch using testing to compare and find the best material alternative for your design and service conditions. Contact us today to learn more.