Most plastic materials, derived from petroleum, are inherently flammable. This means the plastics around us can essentially act as solid fuel. To significantly improve plastic flammability resistance and reduce the risk of ignition and flame spread, flame retardants are frequently added to plastic formulations. Some plastics, like poly(vinyl chloride) (PVC), possess natural plastic flammability resistance and therefore require minimal or no additional flame retardants. To give engineers and designers an understanding of a plastic’s tendency to ignite and spread a flame, a flammability rating is often assigned. But what does this rating truly signify? This article aims to clarify common misunderstandings surrounding these ratings, particularly the UL 94.

Misconception of the UL 94 Rating

Misconception of the UL 94 Rating

It’s a widespread misunderstanding to believe that a “UL 94 rated plastic” signifies the material will not burn. Many engineers who specify plastics for molded parts or assemblies share this misconception. The UL 94 test standard doesn’t definitively state whether a material will burn or not. Instead, it offers insights into the plastic material’s ignition characteristics under controlled laboratory conditions.

The UL 94 tests are conducted on bar or plaque-shaped specimens, and these controlled conditions rarely replicate real-world scenarios. Furthermore, the actual part’s geometry plays a critical role in whether it will ignite or spread a flame. The test geometry can sometimes overstate, or more often, understate the true plastic flammability resistance of the material in its final application.

The UL 94 Test Explained

The UL 94 test involves exposing specimens to a controlled flame under specific conditions.

- Horizontal Burn (HB) Test: A 5-inch by 0.5-inch by 0.118-inch specimen is held horizontally and exposed to a flame for 30 seconds. A plastic material earns an HB rating if the flame self-extinguishes or if the burn rate is less than 3 inches per minute. The HB rating is considered the easiest UL 94 test to pass, and importantly, a plastic can still receive an HB rating even if it ignites and spreads a flame.

- Vertical (V) Orientation Test: This is a more challenging test. A 5-inch by 0.5-inch specimen, typically 1/32 inch, 1/16 inch, or 1/8 inch thick, is placed vertically and exposed to a flame for 10 seconds. If the sample doesn’t ignite or the flame self-extinguishes, it’s exposed to the flame for another 10 seconds. Igniting the sample at its bottom allows the flame to burn the plastic above it, feeding the flame and making it a more aggressive test. A cotton ball is placed below the specimen to detect any flaming drips of plastic.

UL 94 flammability testing.

The plastic receives a “V” rating based on the following results:

- V-0: The sample self-extinguishes within 10 seconds, with no flaming drips.

- V-1: The sample self-extinguishes within 30 seconds, with no flaming drips.

- V-2: The sample self-extinguishes within 30 seconds, but flaming drips that ignite the cotton are permitted.

It’s crucial to understand that a plastic material can achieve a “V” UL rating even if it doesn’t self-extinguish immediately or if it produces flaming drips that could ignite other materials.

Why UL 94 is an Important Test/Rating for Plastic Flammability Resistance

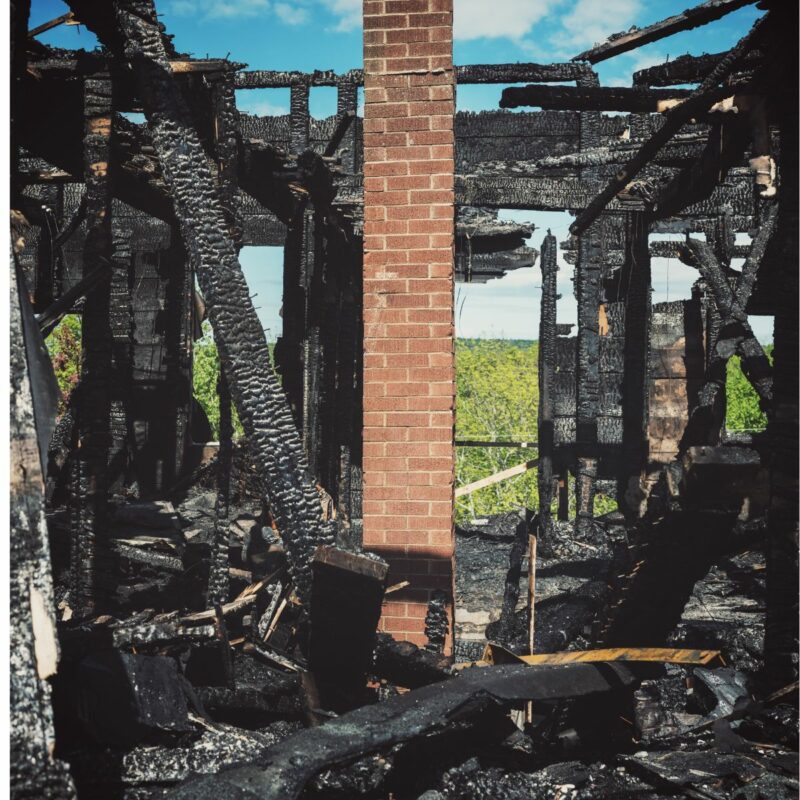

While the UL 94 test doesn’t definitively indicate whether a plastic material will burn, it provides a relative measure of its plastic flammability resistance. It also offers insight into how quickly a flame will spread. Often, the primary goal isn’t to completely stop a flame, but to slow its advancement. This crucial delay can provide valuable time for people to evacuate a structure where a fire has started.

Furthermore, many fire events in electrical appliances are brief, lasting only a few seconds. A material with a UL 94 rating might never ignite under these conditions, whereas an unrated material could ignite and spread the flame rapidly and aggressively.

Summary

In essence, plastic materials are hydrocarbons commonly enhanced with additives to improve their plastic flammability resistance. Perhaps the most important takeaway is that a UL 94 rated plastic material can still ignite, spread a flame, and contribute to a fire event. It’s incorrect to assume that if plastic materials in an assembly are UL 94 rated, there are no combustible materials present.

However, this doesn’t diminish the importance of the UL 94 rating. On the contrary, it provides engineers and designers with a vital metric regarding a plastic material’s propensity to ignite and spread a flame. It’s also worth noting that other test methods (e.g., ASTM, IEC, FMVSS, FAR) are used to measure or rate a plastic material’s behavior during a fire.