This article originally appeared in Plastics Engineering Magazine – August 2014

Failure analysis-backed root cause analysis thwarts the tendency to “theorize before one has data” when failures arise.

When a plastic part fails, there are a number of responses that can arise. At times, some people will deny the existence of the problem, often questioning the motives of those identifying the problem. Others will decide that the problem will go away—that it is a temporary situation that warrants no further action. Experience, however, shows that plastic failures rarely resolve themselves. Such problems may subside temporarily, only to resurface and often escalate.

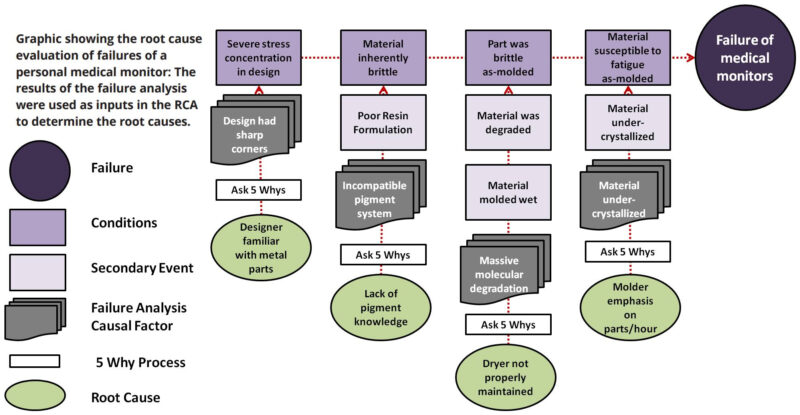

Commonly, a part failure leads to a team meeting in which multiple theories regarding the cause of the failure are espoused. Theories may arise from random opinions or as part of an organized root cause analysis (RCA). In either case, the theories are typically based upon conjecture, without scientific data.

Finally, the failure can be studied using a methodology to allow science to direct the investigation. As U.S. Navy Rear Admiral Grace Hopper once said, “One accurate measurement is worth a thousand expert opinions.” A failure analysis provides the sound scientific data needed to evaluate the problem.

This article presents a typical process for identifying a root cause, with failure analysis as a key step in providing valuable input and direction. The determination of root cause is an interdisciplinary task. In addition to the failure analyst, the team often includes representatives from quality, design, manufacturing, and the end-user. Each instance of failure is certainly different, and the process outlined here will be adjusted on a case-by-case basis as merited by the circumstances. (note: The focus of this treatment is on industrial failures where problem-solving is the primary focus, different than legal cases which include many other aspects not covered in this article.)