This article originally appeared in Plastics Engineering Magazine – July 2015

Continuous stress over long periods leads to creep rupture.

This article addresses one of the most important, yet least understood, plastics failure mechanisms, creep rupture. Creep rupture occurs within plastic parts that are exposed to continuous stress over an extended period of time. Creep is the tendency of a solid material to deform permanently under the influence of constant stress: tensile, compressive, shear, or flexural. It occurs as a function of time through extended exposure to levels of stress that are below the yield strength of the material. Creep is the result of the inherent viscoelastic nature of polymers that causes time dependency.

Prolonged static stresses lead to a decay in apparent modulus that is associated with localized molecular reorganization of polymer chains. At stresses below the yield point, stress-relief molecular reorganization proceeds through disentanglement, as there is no opportunity for yielding. Stresses above the yield point result in plastic deformation, which is not fully recovered after removal of the stress. This macro response takes place through permanent molecular rearrangement.

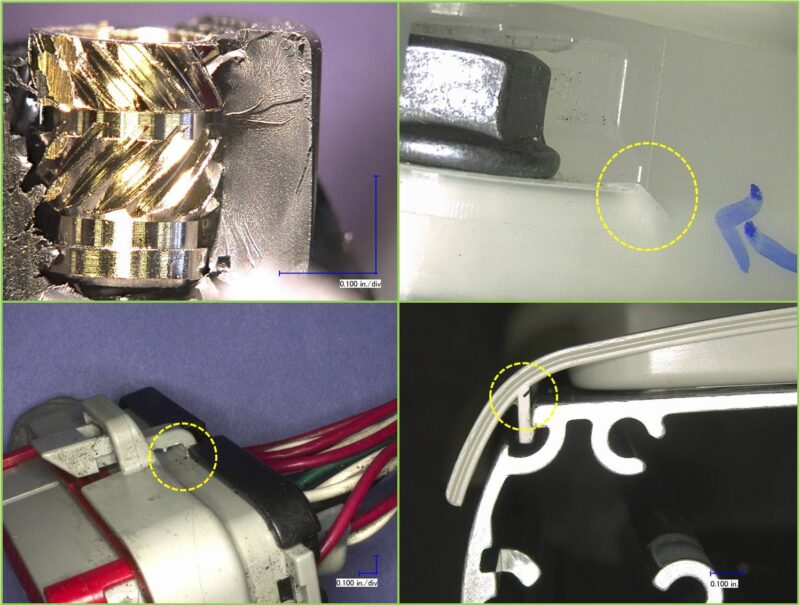

Failure within a plastic article through creep loading can occur either through excessive deformation that renders the part dimensionally unusable or through cracking associated with creep rupture. Cracking within plastics occurs as a response to stress; it takes place as a stress-relief mechanism through disentanglement of the polymer chains. The polymer chains disentangle when the applied stresses, both internal and external, overcome inter-molecular forces such as Van der Waals forces and hydrogen bonding between the polymer chains.