Recently, I worked on a failure analysis of a part injection molded from a poly(ethylene:chlorotrifluoroethylene) copolymer (ECTFE) used in a chemical transport application. While I am generally familiar with this material, I was looking for some additional background. I found three great sources:

- The book, “Technology of Fluoropolymers” by Jiri Drobny

- The online database, “polymerdatabase.com”

- The “Halar® ECTFE Design & Processing Guide” from Solvay

ECTFE is a partially fluorinated, semi-crystalline plastic resin which offers a relatively unique property set:

ECTFE is a partially fluorinated, semi-crystalline plastic resin which offers a relatively unique property set:

- Chemical resistance

- Fire resistance

- Broad continuous use temperature

- Good impact resistance

- Electrical insulator

- Melt processable

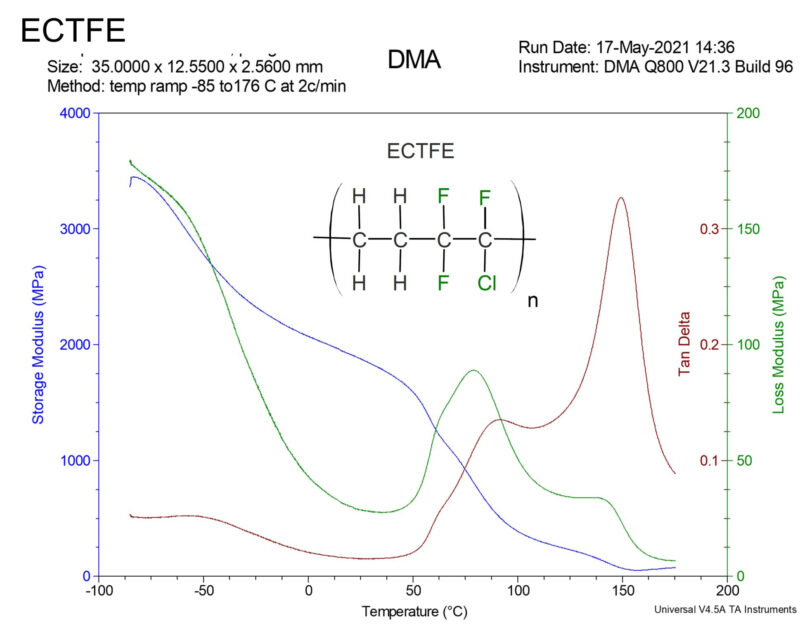

As part of the failure investigation, I performed a dynamic mechanical analysis (DMA) temperature sweep. DMA is an extremely useful thermal analysis technique to evaluate polymeric materials. It provides information on the physical properties (modulus) of the material across a wide temperature range. This is valuable in understanding how the material will behave with temperature and time.

The obtained results indicated that the material underwent a relatively stable reduction in storage modulus with increasing temperature through approximately 50 °C, representing the onset of the glass transition within the material. A glass transition temperature of 79 °C was determined, by convention, as the localized maximum in the loss modulus. From 50 °C, the material underwent a steady decline in modulus with increasing temperature through approximately 100 °C. Above 100 °C, the rate of modulus reduction declined. This is expected to continue through crystalline melting. Overall, the observed performance was consistent with that generally expected for a semi-crystalline polymer passing through glass transition and approaching melting. Specifically, the behavior was in agreement with that expected for an ECTFE resin.