- This event has passed.

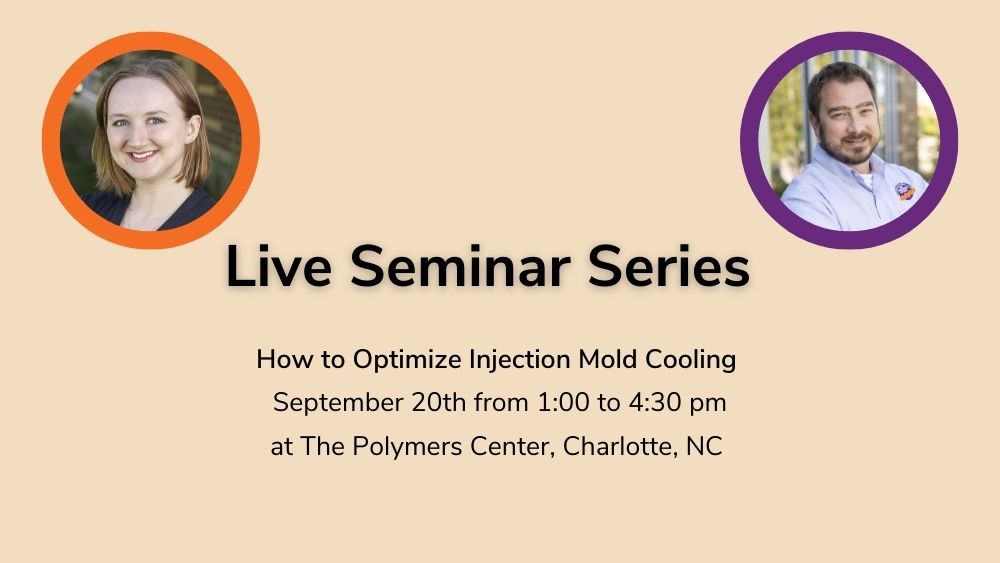

How to Optimize Injection Mold Cooling – LIVE IN PERSON!

September 20, 2023 @ 1:00 pm - 4:30 pm EDT

Free

The goal of this LIVE, free, half-day seminar series at The Polymer Center is to help you optimize the cooling of your injection molds to improve part quality and reduce cycle time. The series is targeted at design engineers, injection molders and toolmakers and will include the following seminars along with a Q&A session:

- How your Cooling Line Layout and Mold Design is Influencing your Part Cost and Part Performance

- Cooling Analysis Strategies to Optimize Your Mold Design Using Injection Molding Simulation

- Benefits of Using High Temperature Pressurized Water for Mold Temperature Control

By the end of the half-day seminar, you will learn:

- How cooling line layout influences part quality.

- How cycle time is affected by the efficiency of a mold’s cooling system.

- How injection molding simulation can be used during any stage of the part or mold design process to optimize part quality, cycle time, and dimensional stability of a part.

- How high temperature pressurized water can be used to achieve high mold temperatures, which are needed to process high-performance engineering resins.