Plastic Injection Mold Design Advanced – LIVE IN PERSON

Take your understanding of the inner workings of injection molds to the next level. With a focus on cost savings throughout, work on mini-projects at each important juncture in order...

Take your understanding of the inner workings of injection molds to the next level. With a focus on cost savings throughout, work on mini-projects at each important juncture in order...

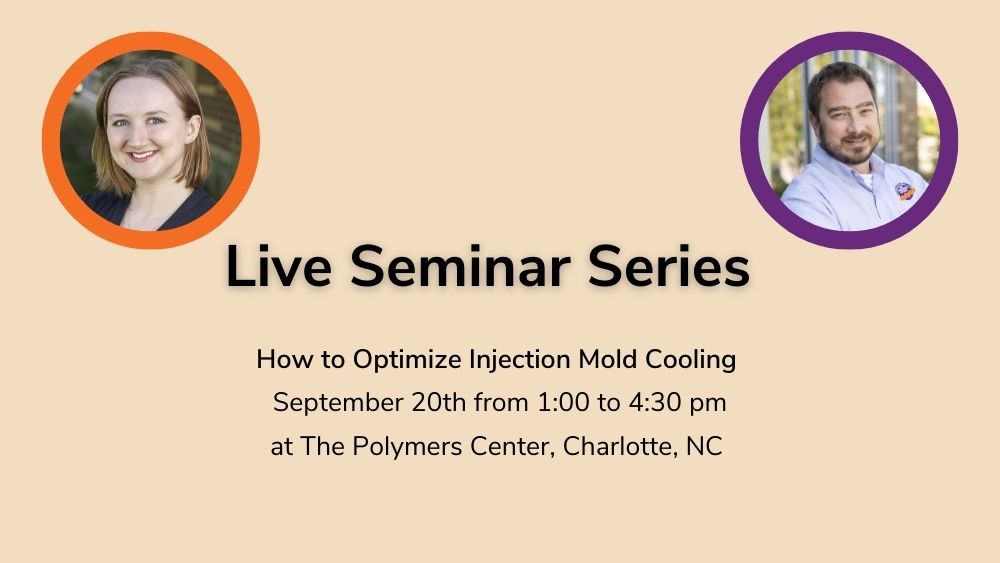

The goal of this LIVE, free, half-day seminar series at The Polymer Center is to help you optimize the cooling of your injection molds to improve part quality and reduce...

This event is the fourth, and last, in our series on how to successfully design and manufacture parts using glass reinforced plastics. Significant time and effort is put into optimizing...

The trend of replacing traditional metal materials with plastics has continued to accelerate over the last decade. While there are numerous factors that are driving this trend one of the...

The need to shorten product development timelines while mitigating risk is a real challenge for designers and program managers. While significant time and effort is spent on the design and...

Injection molding is often selected as a manufacturing process when tight tolerance, high quality parts are required. To meet the ever-increasing customer demands for their parts, while controlling part cost,...

Plastic part failures cause costly production delays and performance issues. This presentation demonstrates how combining structured Root Cause Analysis (RCA) with Plastic Failure Analysis techniques—like fractography, thermal analysis, and material...

Are you tired of costly design flaws in plastic parts that surface only after mold development? The conventional design cycle often isolates design from manufacturing, missing crucial interdependencies between part...