This paper was originally published and presented at The Society of Plastics Engineers’ ANTEC in 2004

Polycarbonate is an important plastic molding resin used to fabricate many engineered components. Because of its widespread usage, many different types of failures can result from various service conditions. Evaluating these failures through a systematic analysis program allows an assessment of how and why the parts failed. An essential portion of the failure analysis process is the fractographic examination, which provides information about the crack origin location, and the crack initiation and extension modes. The focus of this investigation was to characterize the surfaces of intentionally cracked laboratory samples in order to gain a more thorough understanding of polycarbonate fracture mechanisms. This paper will document some of the key fracture features associated with various polycarbonate failure modes.

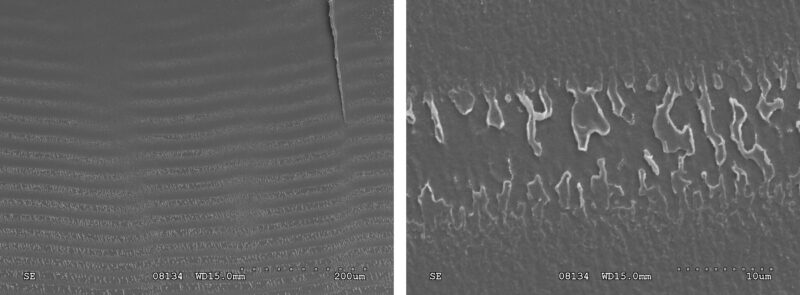

Scanning electron images showing bands of ruptured craze remnants of the fracture surface of a polycarbonate part associated with environmental stress cracking (ESC).

Polycarbonate is a key molding resin used to produce engineered components in numerous applications, including the medical, appliance, and automotive industries. The widespread use of polycarbonate makes it one of the most important plastics within the group of materials commonly referred to as “engineering resins”. The estimated 2002 demand for polycarbonate was 2,000,000 tons. Given this relatively high volume, together with the diverse usage, it is not unexpected that a wide variety of different failure modes are encountered with polycarbonate components. Additionally, while polycarbonate is known for its inherent ductility, its susceptibility to chemical and other environmental effects produces a disproportionately high failure rate, relative to other plastic materials. In the author’s experience as a failure analyst, approximately 20% of all failure investigations are conducted on parts produced from polycarbonate. This is a relatively high number of failures, given the vast number of resins used to mold engineered products.

A thorough understanding of the failure mechanisms of polycarbonate is important, especially in light of the incommensurate failure rate. A key component of a proper failure investigation is the examination of the fracture surface via scanning electron microscopy (SEM), which allows for evaluation at high magnification with great depth of field. Fractography is used to characterize the mode of the failure and can provide invaluable information regarding the stresses and conditions leading to the failure. In this investigation, molded polycarbonate specimens were stressed under several different conditions to intentionally create laboratory failures. A fractographic examination was subsequently conducted in order to understand and document the resulting fracture surface features. This study was conducted to further the understanding of the failure mechanisms routinely observed with polycarbonate parts.

The includes failure modes covered include:

- Tensile overload

- Tear loading

- Impact loading

- Hydrolysis

- Environmental stress cracking (ESC)

- Cyclic fatigue