Staphylococcus bacteria on a surface

The antimicrobial plastics market is projected to reach 43.1 billion USD by 2023, at a compound annual growth rate of 7.8% from 2018. This projection was made prior to the development of the current COVID-19 crisis, which is expected to increase demand for these types of additives even more. This article will look at the different types of antimicrobial additives available with a focus on those for use in plastics, their benefits, and challenges.

What are Antimicrobial Additives?

An antimicrobial additive is an active agent that when included in the processing of a material will inhibit the life or growth of microbes. These microbes can include a variety of organisms such as bacteria, mold, fungi, algae, and even viruses.

The result of using antimicrobial additives can mean the production of intrinsically cleaner, more robust, and longer lasting products by means of:

• Reducing illness and infection causing bacteria

• Resisting the growth of unpleasant mold and mildew

• Minimizing stain and odor causing bacteria

• Inhibiting physical degradation from bacteria and fungi, which feed on plastics and their additives

These additives provide benefits for several environments such as, hygiene critical, high-traffic environments like healthcare facilities, schools and offices, food processing plants as well as for outdoor applications, where constant environmental stresses will dramatically reduce the life of an untreated product.

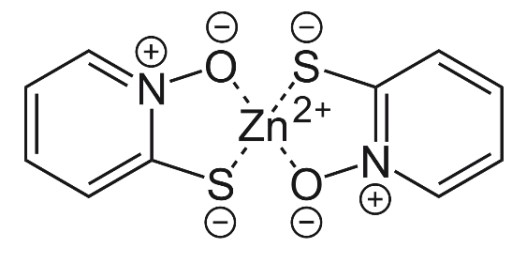

It is important to note that antimicrobial additives are not one-size-fits-all, as different additives are needed in particular applications and to target specific microbes. Antimicrobial additives can be split into two categories: organic and inorganic. Organic additives include, but are not limited to, phenolic compounds, various isothiazolinone treatments, thiabendazole and zinc pyrithione. Inorganic additives include compounds based on metals such as silver, copper, and zinc.

Zinc pyrithione organic antimicrobial compound

Organic Antimicrobials

Phenolics offer a cost-effective range of antimicrobials that can be utilized in a wide variety of applications including pulp, paper, paints, adhesives, inks, and the construction industry. Isothiazolinone treatments are often used for “in packaging” preservation of industrial and household products, such as floor cleaners, laundry care, car care, air fresheners, wet wipes, hair care products, sunscreens, and cosmetics. Thiabendazole is an antifungal agent used to inhibit the growth of mold and mildew in a variety of products including adhesive films, paint films, paper products, heating and cooling system filters, room air cleaners/purifiers, and textiles. Zinc pyrithione can be incorporated into materials and applications which may be expected to have greater exposure to mold and fungi, as well as providing excellent antibacterial protection. It can be incorporated directly into paints as well as used in the manufacture of foams and textiles.

Organic antimicrobials have value in a wide range of applications and products. However, incorporating organic antimicrobials into molded plastic products have limited effectiveness. Organic antimicrobials are relatively small molecules that are incompatible with the polymer matrix. The result is that the molecules leach to the surface where they interact with the microorganism preventing its reproduction. This is often referred to as a biostatic effect. This leaching limits the useful life of the additive, especially on regularly cleaned surfaces, which leads to its use in consumable and disposable products. This leaching can also cause discoloration of the product and an unpleasant taste in applications with food and water contact. Organic antimicrobials are sensitive to high processing temperature making them challenging to successfully incorporate in thermoplastic materials.

Inorganic Antimicrobials

Inorganic antimicrobials are more likely to be incorporated into molded plastic products. Many of these additives are based on metal ions that are unreactive until released in association with another agent, such as moisture. These antimicrobials remain stored in the polymer being released gradually to the surface, providing continual, long lasting protection. These additives offer both biocidal and biostatic effects. A biocidal effect is one that kills the organism while a biostatic effect prevents reproduction of the organism.

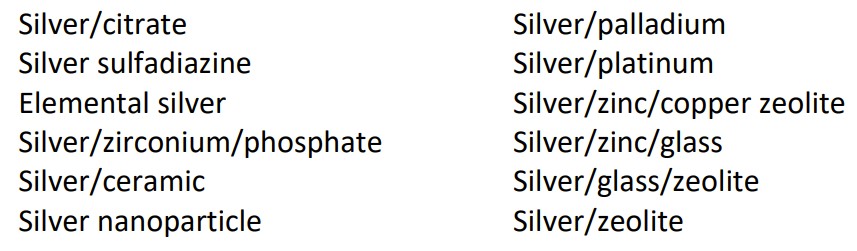

Silver-based compounds dominant today’s inorganic antimicrobial market and can include the following:

These compounds have excellent efficacy against bacteria. However, much higher concentrations are required to be effective against fungi and algae. As a result, these compounds are not seen as a cost-effective solution for this purpose. Two important industries currently utilizing inorganic antimicrobial technologies include food packaging and healthcare.

Packaged raw beef

Food Packaging

Active antimicrobial food packaging is a new generation of packaging. These antimicrobial additives are incorporated into food packaging systems to inhibit, retard, or inactivate microbial growth to extend the shelf life of food products. These additives use silver ion technology and can be incorporated into common film materials such as polyethylene (PE), poly(ethylene terephthalate) (PET) and polypropylene (PP) as well as biodegradable polymers constructed from polylactic acids (PLAs). These films can then be used in the production of single and multilayer packaging for bags, pouches, labels, lids, trays, liners, and wraps. In the meat industry, this technology can inhibit the growth of common bacteria inside the package therefore, keeping the product fresh longer. Incorporating this technology into external packaging works to impede the growth of common food poisoning bacteria, reducing the risk of bacterial transmission from the outer packaging at the point of sale.

Healthcare

Antimicrobial additives for plastics are providing important protection against the spread of healthcare associated infections (HAI). This is a significant concern for medical plastic components that are inserted into the body and exposed to bodily fluids for extended periods of time, such as catheters. The general mechanism of infection related to these type of healthcare devices starts by floating microorganisms attaching themselves to the surface of the plastic. Colonies of bacteria then begin to grow and permanently anchor themselves to the plastic surface. A biofilm formation results as these bacteria colonies grow and mature. Infection in the patient then occurs when the biofilm detaches from the plastic substrate.

Antimicrobials used today fight infection by preventing the attachment of bacteria to the surface of plastics and inhibit their growth. Agion™ antimicrobial technology developed by Sciessent incorporates both silver and copper ions in a zeolite carrier. The zeolite delivery system allows for a controlled and effective release of the ions, on demand, which results in killing and inhibiting the growth of bacteria, viruses, mold, and fungi over long periods of time. This stable ion exchange process is non-reactive and allows the compound to be used in virtually every imaginable manufacturing process. The moisture in the environment causes a controlled release of the copper and silver elements through a proprietary ionic exchange. This technology essentially fights cell growth by preventing respiration (suffocation), inhibits cell reproduction (sterilization) and disrupts cell metabolism (starvation). This type of additive is incorporated into plastic compounds used for device handles, bedrails, and diagnostic equipment housings.

Antiviral Protection

Historically, testing of antimicrobial additives for efficacy against bacteria and fungi have been more prevalent because it is simpler and more cost-effective to perform. The testing of antimicrobials for effectiveness against viruses requires living host cells, which is much more difficult to accommodate in a controlled lab environment. Many antimicrobial additives based on silver compounds have been tested and proven to provide effective protection against viruses such as H1N1, Avian Influenza, and Influenza B, to name only a few.

To produce an antimicrobial product, you need to ensure that the type and amount of antimicrobial additives used impart the same protection once compounded into your selected resin and then molded into a solid surface. A test standard to measure the level of antibacterial activity on plastic surfaces, ISO 22196, has been available since 2007. A similar standard for the assessment of antiviral activity on plastic surfaces, ISO 21702, was just released in 2019. This new standard will help to enable the proliferation of antiviral protected products. These types of products are expected to see an ever-increasing demand especially with the surge in frequency of viral pandemics that have occurred in the last decade.