I was working on the material selection project, and considering the unique properties of nucleated polypropylene. Polypropylene (PP) is a semi-crystalline plastic having a relatively straightforward molecular structure that promotes a significant level of orderly molecular arrangement into crystalline domains. When semi-crystalline polymers crystallize from the melt state during processing, lamellae organize to form larger complex structures called spherulites. The spherulites continue to develop and grow until they impinge on an adjacent spherulite at which point the growth stops. The properties of semi-crystalline polymers are dependent on the size of the spherulite structures as well as the crystalline orientation. The size and orientation of the crystalline structure affects the mechanical, chemical, physical, and optical properties of the molded material.

In nucleated polymers, including polypropylene, the addition of formulation additives, increases the rate of crystallization. Specifically, crystallization occurs earlier as the material cools during processing. Correspondingly, the crystallization also occurs at a faster rate. This results in smaller crystalline spherulite structures with a significantly higher concentration. There are two basic types of nucleating agents:

- Insoluble particulate additives, which are typically high melting chemicals, and are melt compounded into the base polymer. The particles serve as irregularities on which polymer crystalline growth can initiate.

- Soluble nucleating agents, which typically have low melting points and are soluble in the melted polypropylene. These additives crystallize early as the material is cool, and facilitate the crystallization of the polypropylene.

Polypropylene is generally recognized as a relatively easy polymer to nucleate. This is attributed to the rate of crystalline structure formation, which is slow enough to allow the nucleating agent to have a significant impact.

Nucleating agents are often used with a polypropylene resin as their addition allows for decreased cooling time of the polymer, and as such shorter cycle times. Additionally, nucleating agents can help to reduce warpage and produce more uniform shrinkage within the molded part due to the smaller, but more dense spherulite crystalline structure.

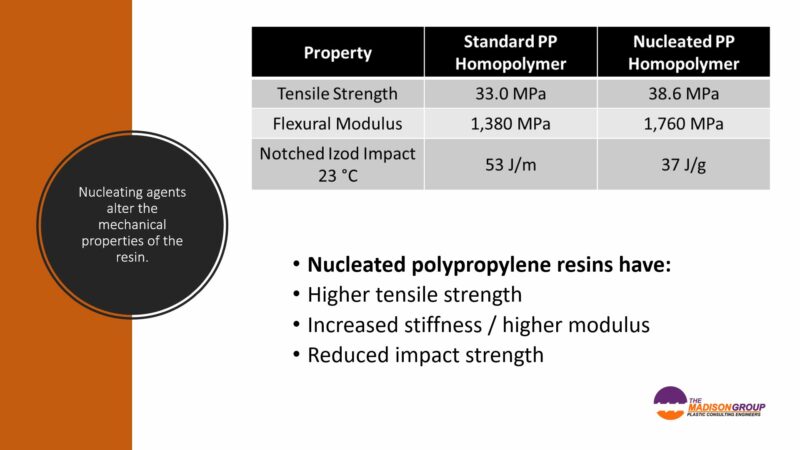

In addition to processing, the addition of nucleating agents to polypropylene can alter the properties of the molded article. Most notably, nucleating agents will typically result in increased strength and stiffness, but reduced impact resistance, compared with corresponding not nucleated polypropylene resin.

A specific type of nucleating agent is called a clarifier. Generally, clarifiers provide even smaller crystalline spherulites that scanner less light. This resulted in a greater level of transparency and improved clarity.

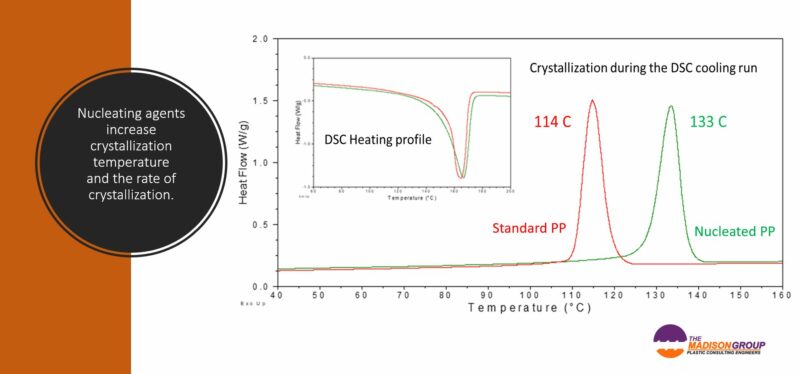

Nucleating agents can be identified through differential scanning calorimetry, particularly as a noted increase in the recrystallization temperature.