This paper was originally published and presented at The Society of Plastics Engineers’ ANTEC in 2016

Four case studies are presented to illustrate failures associated with the interaction between plastic components and metal fasteners. The use of metal fasteners to secure and assemble plastics is widespread. The presented cases illustrate how the failure analysis process was used to identify the failure mechanism as well as the primary factors responsible for the failures. The four cases depict representative failures involving varied designs and service conditions.

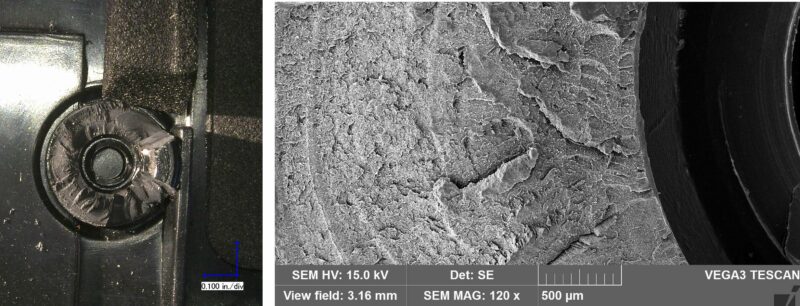

The fracture surface of a plastic housing insert boss exhibits brittle fracture features, without apparent macro ductility. The SEM image shows the presence of multiple crack origins around the inner diameter of the boss.

The need to secure plastic components is prevalent in the manufacture of assemblies in many industries, including automotive, appliances, electronics, medical, durable goods, and construction. Joining plastic components to other plastic parts or metal parts often involves the use of mechanical fasteners, such as screws, inserts, or rivets. The joining of plastic parts is inherently more complicated than assembling two metal components because of the fundamental differences in physical properties, including strength, chemical resistance and susceptibility to creep and stress relaxation.

There are a variety of fastening techniques available to the product designer. Threaded inserts are a very common way to join metal parts to plastic parts using threaded fasteners. The most common applications include the pressing of brass or steel inserts into plastic components by thermal or ultrasonic processing, or by overmolding. This is achieved by melting the plastic into a knurl on the metal part, which acts as a mechanical joint once the plastic is cooled. Another widespread fastener option for plastic assemblies is self-clinching screws. Other common mechanical fastening techniques include rivets and interference springs.

The weakest sections of many plastic part designs are the joints and assembly points2. Because of this, cracking of plastic components at fastener joints is common. If failure does occur within a fastened component, a failure analysis can provide a thorough understanding of the nature and cause of the failure. This knowledge is critical to correcting the failure, and avoiding future instances.

Through the failure analysis process, particularly fractographic examination, it is possible to understand the impact of metallic fasteners on mating plastic components. The presented case studies illustrate the diversity of failures that can result from the interaction between metallic fasteners and plastic components. In particular, the presented case studies showed:

- Environmental stress cracking associated with residual chemicals on the metal fasteners and stress imparted by self-tapping screws

- Mechanical overload resulting from excessive stress from the insertion of screws and the transfer of stress to the plastic boss

- Creep rupture produced by continuous static stress associated with interference between rivets and the mating plastic, exacerbated by stress concentration from the fastener’s sharp corner features

- Mechanical damage generated by sharp features on metal shaft springs that lead to fatigue failure through repeated actuation

The primary factors prevalent in the failures were:

- Sharp corner features within the fastener acting as points of stress concentration

- Extended time under continuous levels of relatively low stress associates with interference between the fastener and the plastic

- High strain rates associated with assembly or insertion of the fastener

- Cleanliness of the metal fastener resulting in chemical exposure

In most cases, these are not a concern with complete metal assemblies, but can be major issues with plastic.