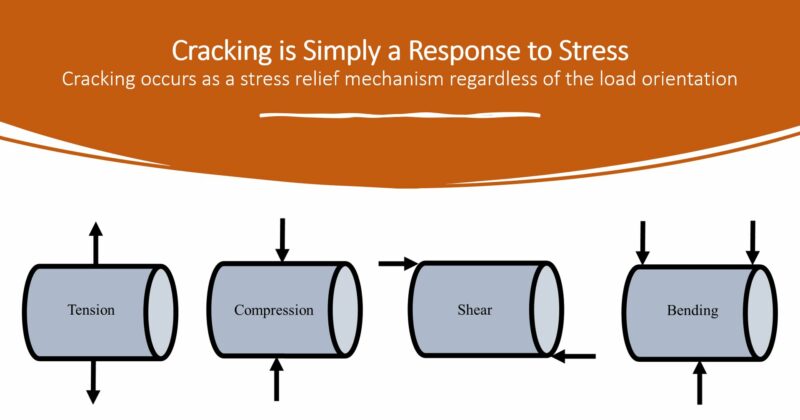

Cracking within a component is simply a response to stress.

When a part cracks, regardless of the material, it is an indication that the stress exceeded the strength of the material over a given time period, under specific loading conditions. Cracking is a stress relief mechanism. This is true:

- Whether the stress is internal or external

- Whether the stress is static, intermittent, or cyclic

- Whether the stress is associated with loading in tension, compression, shear, or bending.

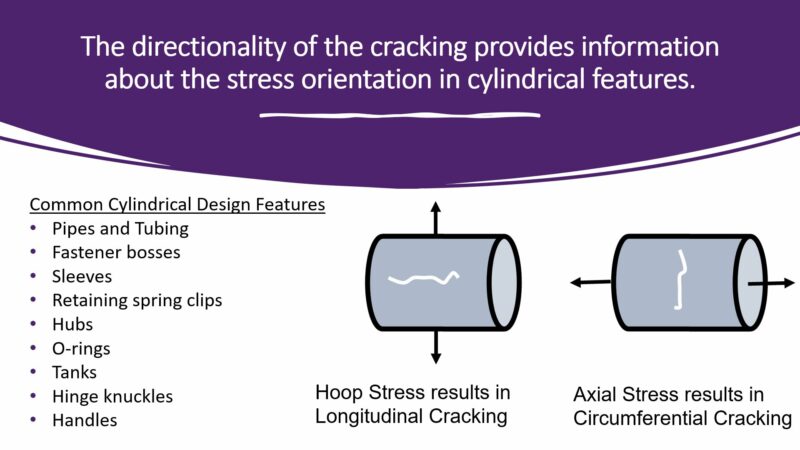

A fractographic examination can help to understand the stress responsible for part failure. Fractography is the examination of the fracture surface and surrounding area on a failed part, typically performed across a range of magnifications using visual and microscopic techniques. The fractographic examination is a key part of a failure analysis. It provides information on the mode of failure, as well as the type, magnitude, form, and directionality of the stresses.

For example, I have worked on a number of failures within cylindrical design features. At the most basic level, fractography can be used to determine if the stress responsible for the failure was axial which results in circumferential or transverse cracking, or hoop which produces longitudinal cracking.

Do not overlook fractography as a powerful step in a failure investigation. With experience, mechanical insight, and materials knowledge, fractography can provide information allowing an understanding of the stress associated with the part failure.