Dynamic mechanical analysis (DMA) is the best method for determining the glass transition temperature for plastics. The glass transition temperature (Tg) represents the temperature at which the forces holding the molecules comprising the amorphous segments of a polymer together are overcome, so that the individual polymer chains are able to undergo large‐scale molecular motions. Transitional temperature of polymer chain stiffness or mobility from glassy state to flexible state. In other words, glass transition temperature (Tg) is the temperature at which the molecules within a polymer chain begin to be in motion.

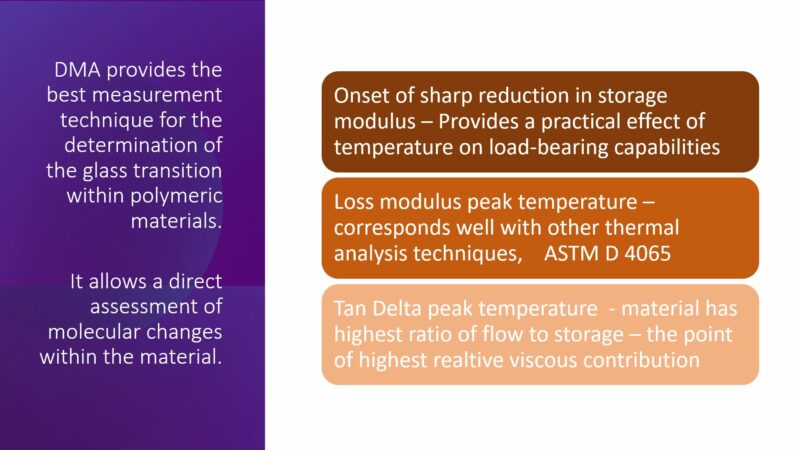

While we talk about a specific glass transition temperature, this transition takes place over a range of temperatures and is not actually a single temperature. An important technique used to assess the glass transition within polymeric materials is dynamic mechanical analysis (DMA). A DMA temperature sweep provides information on the storage modulus (elastic modulus) (E’), loss modulus (viscous modulus) (E”), and the tan Delta as a function of temperature. While other methodologies including differential scanning calorimetry (DSC) and thermomechanical analysis (TMA) can be used to assess the glass transition, the DMA technique is particularly sensitive as it directly measures molecular changes within the material. Even when using DMA, the glass transition can be assessed using three separate techniques, the onset of reduction in the storage modulus, the localized maximum within the loss modulus, or the localized maximum within the tan Delta.

The glass transition temperature determined as the onset and reduction in the storage modulus will be the lowest of the three listings DMA techniques. While not often used, this value is a good indicator of the effect of temperature on the functional stiffness of the material, and can provide a good assessment of when the material loses load bearing capability.

The glass transition temperature determined as the localized maximum within the tan Delta will be the highest of the three DMA techniques. The peak in the tan Delta is the point in the glass transition within the material has the highest proportion of viscous response compared with elastic response under conditions of deformation. This is the most common value indicated for the glass transition temperature using DMA, and is referenced in ASTM D4065.

The glass transition determined as the localized maximum in the loss modulus represents an intermediate value to the other two techniques. The peak in the loss modulus as important considerations in regard to molecular mobility. As the material approaches and posting the peak in the loss modulus, the energy dissipated increases as the polymer has relatively large segmental motion.

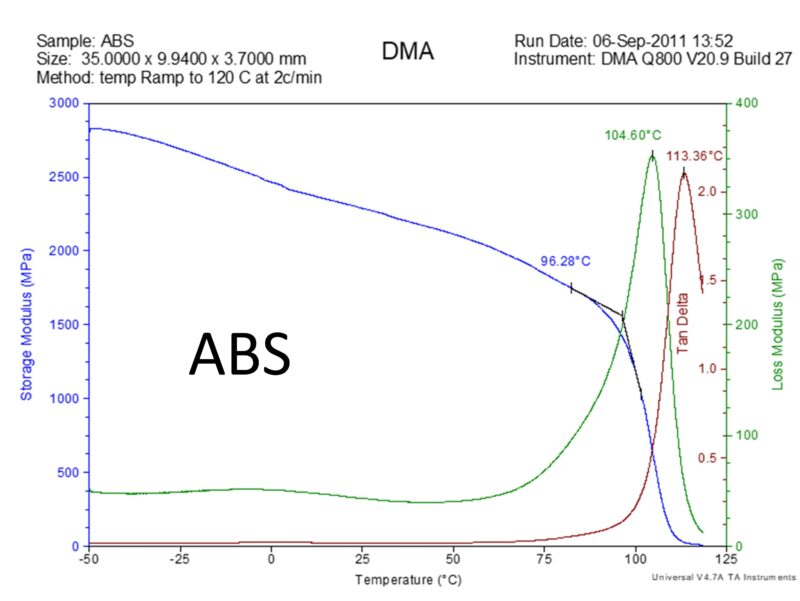

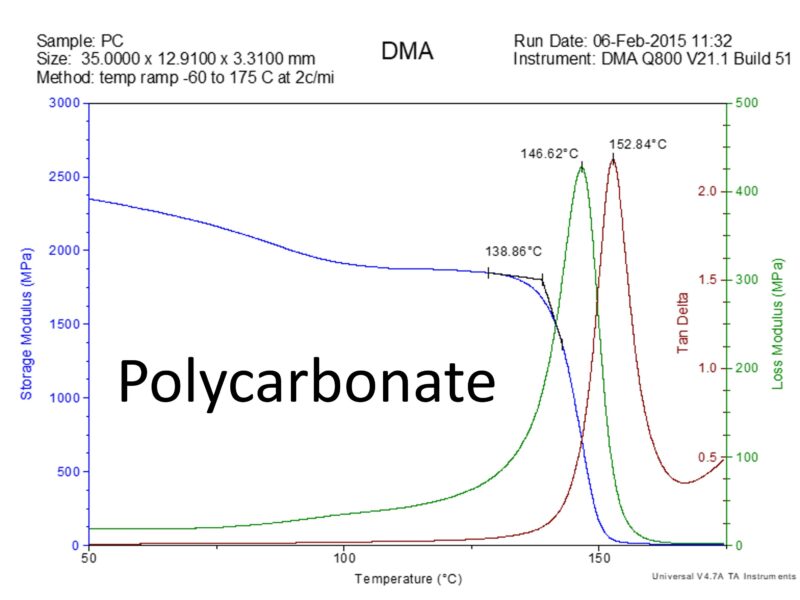

These three approaches are illustrated in the DMA temperature sweeps of poly(acrylonitrile:butadiene:styrene) (ABS) and polycarbonate (PC) below.

DMA temperature sweep of ABS, illustrating the three different methods for determining glass transition.

DMA temperature sweep of polycarbonate, illustrating the three different methods for determining glass transition.

For more information on using DMA to evaluate the viscoelastic properties of plastics, see Unleashing the Power of Dynamic Mechanical Analysis.

For a more thorough treatment of the assessment of the glass transition of polymeric materials, please refer to TA instruments document RH100, https://www.tainstruments.com/pdf/literature/RH100.pdf