When we design and manufacture plastic parts, we put immense effort into optimizing their mechanical, physical, and aesthetic properties. But beyond these initial considerations, it’s critical to ensure the part will adequately perform in its intended environment for its entire anticipated lifetime, without a dramatic reduction in these essential properties. In almost all applications, plastic components are exposed to some form of external or internal chemical agent—everything from everyday hand lotions to fuels, water, or countless other substances. For a plastic part to truly function and perform reliably over an extended period, it must have the inherent ability to withstand these agents. While many chemicals can harm plastics through various mechanisms, such as molecular degradation, one particularly insidious phenomenon is environmental stress cracking (ESC). Understanding how a material will respond to the specific substances it will encounter over its useful life is paramount during the design and material selection phase, and this understanding is best achieved through targeted environmental stress cracking testing.

Why Standard Chemical Resistance Isn’t Enough

One of the primary challenges in gaining this understanding is accurately identifying every chemical a part will be exposed to during use. Once these substances are identified, the natural question becomes, “How do I know how they will interact with my material?” The common first step is consulting chemical resistance tables for the plastic. These tables typically indicate whether cracking develops or mechanical properties decrease when soaked in various chemicals, often using ratings like “Good,” “Poor,” or a scale of 1 to 5. While this information is useful, many plastic parts will surprisingly fail from substances listed as “Good” or “Excellent” on these charts. This is because these tables often don’t fully account for the complex interplay that leads to environmental stress cracking. It’s simply not enough to consider if a material will crack or lose strength purely from soaking in a substance.

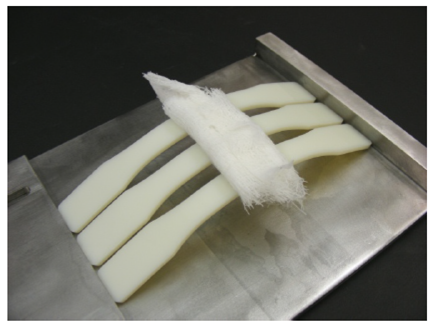

Figure 1. ESC test fixture.

Plastic parts will often behave in a porous manner with certain substances. If you’ve ever used an inexpensive plastic storage container that had spaghetti sauce or salad dressing in it and you forgot to wash it for a week, you’ve likely seen this behavior. You can scrub and scrub, but it will remain discolored. That’s because the sauce or dressing has permeated between the individual molecules of the plastic and into the plastic container. If this can happen with spaghetti sauce or salad dressing, imagine how many substances might do this to your material? This phenomenon underscores the need for effective environmental stress cracking testing.

Understanding Environmental Stress Cracking

Environmental Stress Cracking (ESC) in plastics is a phenomenon based on the simple example above. It’s caused by an external substance permeating into the molecular structure of the plastic, interfering with intermolecular forces. This makes it easier for the individual molecules to slip and slide past each other while the part is in a stressed state. This slow disentanglement can eventually result in crack development and failure. This mechanism is not degradation; it doesn’t attack or break down the individual molecular chains. The information in chemical resistance tables is generally based on the evaluation of the effects of molecular degradation. With ESC, the molecules simply disentangle and slide apart in the presence of stress while in contact with the chemical agent. Compatibility tables often don’t adequately convey this subtle yet significant effect on the plastic, making robust environmental stress cracking testing essential.

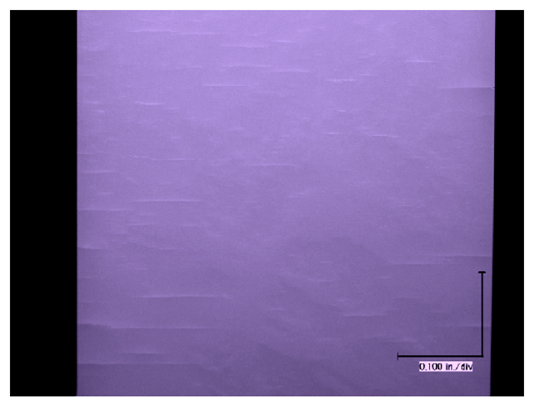

Figure 2. Photomicrograph showing ESC cracking on a test specimen.

The Process of Environmental Stress Cracking Testing

Environmental stress cracking testing conducted to simulate ESC is typically based on ASTM D543 “Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents – Practice B.” This test method essentially places a sample, usually a tensile or flex bar, in a continuously stressed state using controlled strain levels. There are several test fixtures that can be used for ESC testing, one such setup is shown in Figure 1. The setup in Figure 1 bends or flexes the specimen, which creates elevated tensile stresses on the outer edge/apex of the bend. The chemical agent is then locally applied to the surface of the specimen at the apex of the bend. This locally exposed area of the sample is periodically inspected for crack development during the lifetime of the test. An example of typical cracking found during environmental stress cracking testing is shown in Figure 2. By using a sample of known dimensions, the strain level can be calculated, and the test fixture can be set to generate the calculated strain value.

Furthermore, with a known modulus for the material, the stress level can also be calculated. This provides a stress at which ESC will occur when the plastic is exposed to certain chemical agents. When coupled with stress levels predicted in a finite element analysis (FEA) of the part, predictions can be made on whether a part will fail from ESC when in contact with chemicals it’s anticipated to be exposed to during use. This integration of design analysis with environmental stress cracking testing is a powerful tool for proactive material selection.

It’s important to note that ESC can occur even when external loads aren’t applied to the part. Molded-in residual stresses and thermal stresses, in the presence of an ESC agent, can also be sufficient to produce cracking. Whether you’re hoping to avoid future failures or are already experiencing them, environmental stress cracking testing can be a crucial step during the failure analysis of plastic parts and a vital component of the material selection and design process.

This article was originally authored by Jake Nemec.