My wife is a teacher and some time ago she was covering the Scientific Method with her sixth grade students. She commented that conducting a failure analysis follows the scientific method. I thought about it for a while and came to the conclusion that they are significantly different.

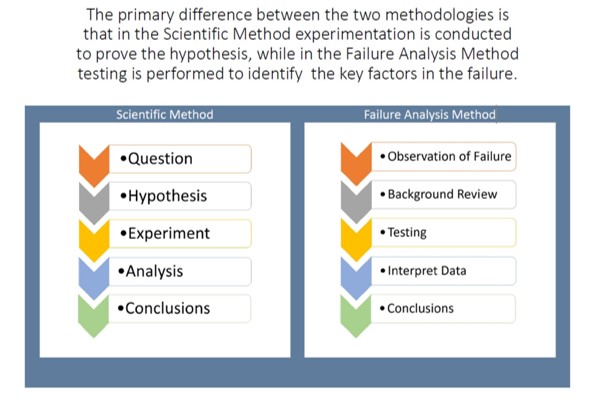

I certainly believe that it is important to follow a rigorous method or process when conducting a failure analysis, and in this regard, the Scientific Method and the Failure Analysis Method are similar. However, the primary difference is that when following the Scientific Method, testing is performed to prove or disprove a hypothesis. The hypothesis comes first. For example, the sixth grade science class hypothesized that lima beans that are watered once a day will grow faster than those watered once a week. In the case of a failed part, the hypothesis might be that the gear failed through fatigue due to improper molding and poor geometric tolerancing of the part.

When conducting a failure analysis, it is important to not form a hypothesis until after the testing is done. I strongly believe that having a preconceived notion regarding the basis of the failure will obscure the failure analyst’s ability to be dispassionate and arrive at the true root cause. When I get a failed part in from a client, I create a plan of attack to include fractographic examination and material analytical testing. Based upon those test results and the background information, I draw a conclusion – form my hypothesis. From there, I will evaluate that hypothesis by additional testing and demonstrating the ability to turn the problem on and off.

Here is a comparison of the two processes:

The Scientific Method

· An idea is raised, and questions are asked, and literature is reviewed.

· Based upon that initial review, and without testing, a hypothesis is reached.

· Testing is then performed to prove or disprove the hypothesis.

· The data is analyzed, and a conclusion is reached – the hypothesis is proven or disproven.

The Failure Analysis Method

· A problem is identified – failure observed.

· A review is conducted of the background information pertaining to design, material, manufacturing, service.

· Testing is then performed to identify the nature and cause of the failure.

· The data is interpreted.

· A conclusion is reached how and why the failure occurred.

Difference between the scientific method and the failure analysis process.