This paper was originally published and presented at The Society of Plastics Engineers’ ANTEC in 2008.

The goal of a failure analysis is to identify the mode and cause of the failure. The assignment of the failure mode is often straightforward through fractographic techniques. Comparatively, the determination of the cause of the failure is often less apparent, but required if proper corrective action is to be carried out. Many times the cause of the failure is related to factors that produce a ductile-to-brittle transition within the material. These factors are associated with material, processing, design, and service issues. This paper addresses the failure modes of thermoplastic resins in regards to a ductile-to-brittle transition as the cause of the failure.

The objective of a failure investigation, regardless of the material, is to identify the mode and cause of the failure. The characterization of the failure mode such as, fatigue, overload, environmental stress cracking, etc… is often straightforward through standard fractographic methods. However, the determination of the cause of the failure is in many cases less apparent. This is particularly true with a plastic component. Thermoplastic resins are utilized in many applications because of their unique property set, including their ductile response to applied stress. This ductility is associated with the viscoelastic nature of polymers and is attributed to their unique molecular structure. In spite of that inherent ductility, most plastic components fail through one of the many brittle fracture modes. Experience through conducting over 800 plastic component failure analyses has shown that less than 5% were associated with ductile overload. The remainder represent brittle fractures of normally ductile materials. Thus, within evaluations of plastic component failures, the focus of the investigation frequently turns to identifying the nature of the ductile to brittle transition. This relatively brittle response to stress is evident through the examination and characterization of the fracture surface morphology.

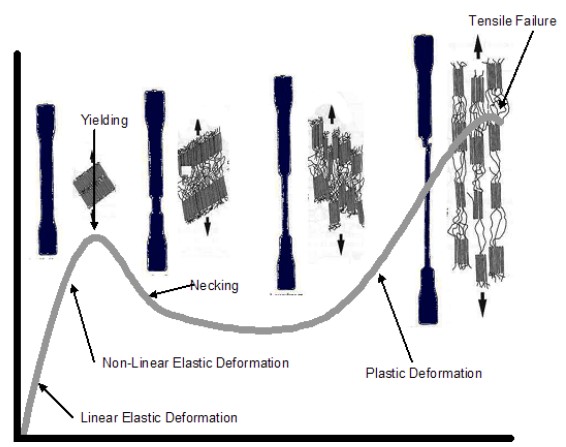

Figure 1 – Typical tensile response of a ductile plastic resin illustrates the failure mechanism as stress increases.

In order to understand the cause of a ductile-to-brittle transition, there must first be a comprehension of the mechanism whereby plastic materials crack. Cracking is simply a response to mechanical stresses, either internal or external. Contrary to popular misconception, cracking of a plastic resin does not represent the scission of the polymer molecules. Although molecular degradation mechanisms, including oxidation and chemical attack, can render the altered material prone to failure, plastic resins do not crack through mechanisms producing gross breakage of individual polymer chains. While mechanical stress will result in a limited amount of chain scission, the primary response is molecular disentanglement, sometimes referred to as slippage. Cracking within a molded plastic resin represents the disentanglement of the molecular structure, by overcoming the intermolecular forces holding the molecules together, including Van der Waals Forces and hydrogen bonding. In ductile failure, the mechanism resulting in cracking includes several steps including linear elastic deformation, nonlinear elastic deformation, yielding, necking, plastic deformation, and finally, failure. Each of these steps is associated with physical alteration of the molecular structure, as represented graphically in Figure 1.

There are numerous factors that influence a ductile-to-brittle transition within plastic materials, such as:

- Temperature

- Stress Concentration

- Chemical Contact

- Molecular Weight

- Degradation

- Filler Content

- Contamination

- Poor Fusion

- Strain Rate

- Time Under Load

- Crystallinity

- Plasticizer Content

These factors are associated with material, processing, design, and service issues.