This paper was originally published and presented at The Society of Plastics Engineers’ ANTEC in 2019

Failures occurred within automotive air conditioning system connectors. The cracking was observed within connectors that had been installed in automobiles, which were part of a durability testing program. The focus of this investigation was a determination of the nature and cause of the failures. The results obtained during the evaluation of the cracked connectors indicated that the failures occurred through a brittle fracture, slow crack initiation creep rupture mechanism of the material. However, the cause of the failure was severe molecular degradation as a result of the durability test program conditions. This paper will review the testing performed to characterize the failure mode and identify the cause of the cracking, while demonstrating the analytical procedures used in the investigation.

The connectors were components of the air conditioning system within vehicles that were used as part of a durability assessment program. The failures ultimately resulted in leakage of the compressor fluid and system failure. The vehicles had been operated aggressively under conditions of high annualized mileage in a severe hot and humid weather climate. In the application, the air conditioning system, and specifically the connectors, are under elevated internal pressure and exposed to a combination of refrigerant and compressor fluid. The compressor fluid was described as a polyalkylene glycol (PAG) oil.

The connectors are injection molded from a 35% glass fiber reinforced nylon 6/6 molding resin. The material was further described as being specially formulated to be heat stabilized and hydrolysis resistant. In addition to the failed components, control parts and molding resin were also evaluated for reference purposes. Unused glycol fluid samples were obtained from the failed installation site and from an air conditioning system that did not have failed connectors on a separate vehicle within the durability testing program.

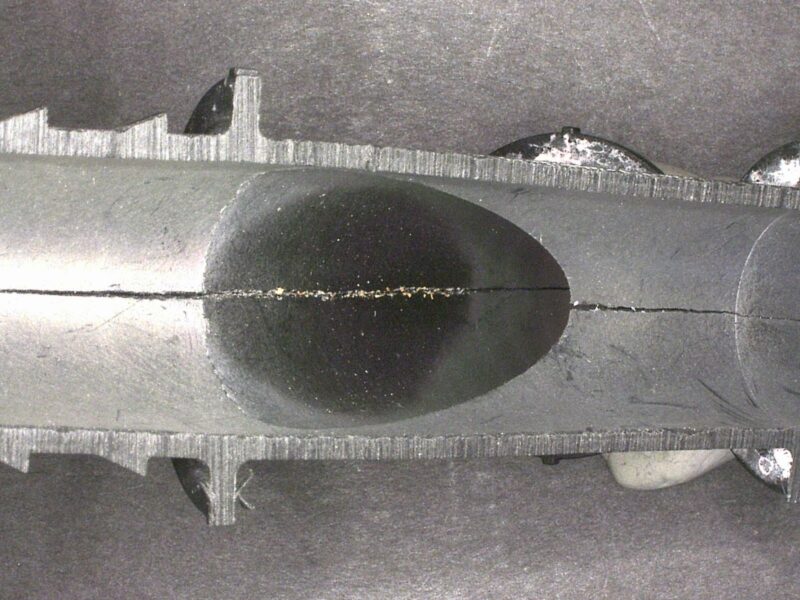

The nylon automotive air conditioning connector exhibited brittle cracking.

The failure analysis of the automotive air conditioning system connectors included:

- Fractography utilizing microscopy and scanning electron microscopy (SEM)

- Fourier transform infrared spectroscopy (FTIR)

- Differential scanning calorimetry (DSC)

- Thermogravimetric analysis (TGA)

- Gel permeation chromatography (GPC)

- Gas chromatography – mass spectroscopy (GC-MS)