This article originally appeared in Advanced Materials & Processes – November 2023

This article explores one of the most commonly used analytical techniques in plastic component failure analysis—Fourier transform infrared spectroscopy—along with a case study to demonstrate its use.

Failure within plastic components can occur in several different ways, including aesthetic alteration, deformation/distortion, degradation, wear, and fracture. In the case of failure involving fracture, a number of common plastic failure mechanisms exist such as ductile overload, impact, creep rupture, environmental stress cracking, and fatigue. Determination of the fracture failure mode involves identifying the crack initiation mechanism and the propagation mode. This is usually ascertained using visual-based techniques such as stereo microscopy, scanning electron microscopy, and the preparation of mounted cross-sections.

Assessing the mode of the failure is often not as difficult as establishing why the part failed. Evaluating why the part failed usually requires analytical testing beyond the visual-based techniques. In many cases, a single cause cannot be identified because multiple factors may have contributed to the failure. All the factors that affect the performance of a plastic component can be classified into four categories: material, design, processing/manufacturing, and service conditions/ environment[1]. These factors do not act independently on the component, but instead act in concert to determine its performance properties.

The main differences between how failure analyses are performed on metal and plastic materials are based primarily on the techniques used to evaluate the material’s composition and structure. Unlike metals, polymers have a molecular structure that includes characteristics such as polymer functional groups, molecular weight, molecular weight distribution, crystallinity, tacticity, molecular orientation, and fusion. These characteristics have a significant impact on the properties of the molded article. In addition, plastic resins are formulated with additives such as reinforcing fillers, plasticizers, colorants, antidegradants, and process aids. It is this combination of molecular structure and complex formulation that requires specialized testing[2]. This article explores one of the most commonly used analytical techniques in plastic component failure analysis—Fourier transform infrared spectroscopy—along with a case study to demonstrate its use.

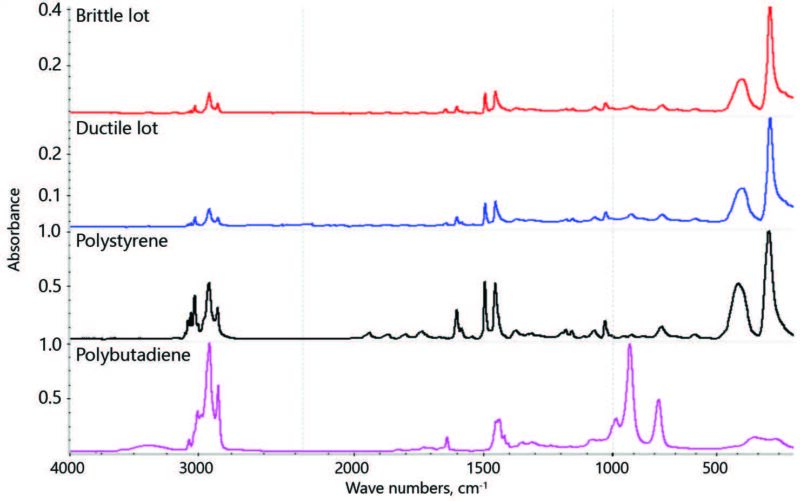

FTIR spectral comparison between brittle lot and ductile lot materials. Both spectra contained absorbances that are associated with styrene and butadiene functionalities, but spectral differences were noted.

Fourier transform infrared spectroscopy (FTIR) is a nondestructive micro-analytical spectroscopic technique that involves the study of molecular vibrations[2]. The analysis results provide principally qualitative, but also some quantitative, information regarding the composition and state of the evaluated material. FTIR uses infrared energy to produce vibrations within the molecular bonds that constitute the material being evaluated. Vibrational states of varying energy levels exist within molecules. Transition from one vibrational state to another is related to absorption or emission of electromagnetic radiation[3]. These vibrations occur at characteristic frequencies, which correspond to functional groups within the molecular structure of the sample. FTIR produces a unique spectrum, which is comparable to the fingerprint of the material. It is the principal analytical technique used to qualitatively identify polymeric materials—and is commonly the first analytical technique used in a plastics failure analysis.