This paper was originally published and presented at The Society of Plastics Engineers’ ANTEC in 2011

Plastic piping systems are an important commercial product used in a wide variety of applications. Because of the diversity of applications and wide range of material used to produce pipes, many different types of failures can result in service. Evaluating these failures through a systematic analysis program allows an assessment of how and why the pipes failed. An essential portion of the failure analysis process is the fractographic examination, which provides information about the crack origin location, and the crack initiation and extension modes. The focus of this investigation was to characterize the surfaces of intentionally cracked laboratory samples in order to gain a more thorough understanding of pipe fracture mechanisms. This paper will document some of the key fracture features associated with overload of various materials used to produce commercial piping systems.

Piping systems find wide utility in the world today and are used in a variety of applications including:

- Gas Distribution

- Water Distribution

- Sewer

- Drainage Systems

- Cable Protection

- Communication

- Industrial Applications

Commercially available pipe, tubing and hose samples representing a range of materials were selected for the investigation. Each sample was mechanically tested by applying high pressure with water until failure. High pressures were achieved by using a mechanical pump, which is capable of producing pressures up to approximately 3000 psi by hand. All failures occurred within 3 minutes of the initial application of pressure with the pump. The prepared fracture surfaces were examined using a Keyence digital microscope.

The materials included as part of this study included:

- Crosslinked Polyethylene (PEX) Pipe

- Polyethylene (PE) Tubing

- Chlorinated Poly(vinyl chloride) (CPVC) Pipe

- Poly(vinyl chloride) (PVC) Pipe

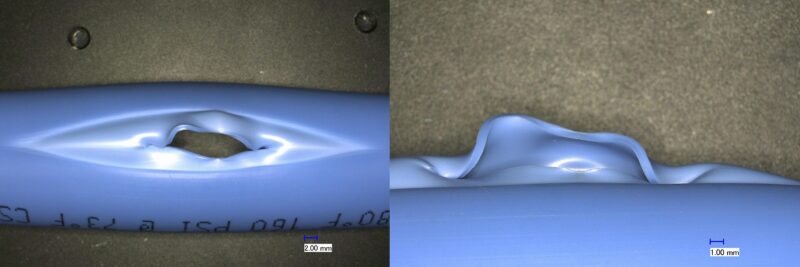

Photomicrographs showing significant deformation of a PEX pipe through pressurization testing.

Based upon the evaluation of laboratory fracture surfaces created on different pipe materials, the corresponding responses to relatively rapid over-pressurization have been documented. The obtained fracture surfaces could easily be used to separate the bulk macro responses as ductile and brittle. The PEX and PE samples displayed a significant level of deformation and distinct yielding. Conversely, the CPVC and PVC samples showed extremely brittle characteristics including substantial crack bifurcation. These macro responses correlate with the inherent tensile and impact properties of the materials.

Interestingly, the observed fracture surfaces showed the opposite response on a micro level. The PEX and PE displayed almost no evidence of micro-ductility, as would be indicated by the presence of stretched fibril or flap formation. Conversely, the CPVC and PVC fracture surfaces showed a relatively coarse textured morphology indicative of micro-ductility at the crack origin locations. Further work will need to be performed in order to indentify the mechanism responsible for this contrasting behavior. In all cases, the longitudinal cracking predicted by the elevated level of hoop stress was observed, as opposed to circumferential cracking caused by longitudinal stress.

This paper was authored by Jeffrey A. Jansen and Thomas G. Loken