Introduction

The appliance industry is one of many revolutionized by plastics, offering a combination of versatility, durability, and cost-effectiveness that traditional materials can lack. From refrigerator liners to blender bowls, plastics are integral to modern appliance design. This article will delve into the world of appliance plastics, exploring the most commonly used types, their properties, key design considerations, and potential applications.

Common Plastics Used in Appliances

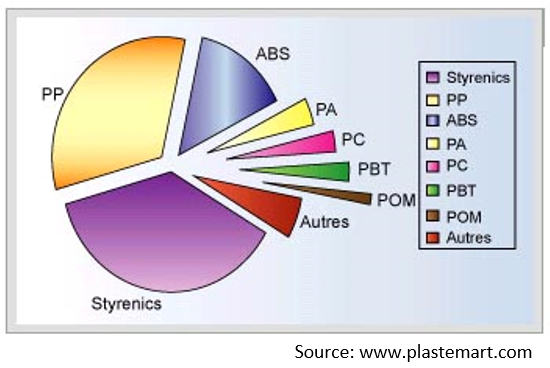

While a variety of plastics find their way into appliances, some stand out for their widespread use: polypropylene (PP), high impact polystyrene (HIPS), styrene acrylonitrile (SAN), and acrylonitrile butadiene styrene (ABS). These are supplemented with other plastics for specific components including nylon/polyamide (PA), polycarbonate (PC), polybutylene terephthalate (PBT), acetal/polyoxymethylene (POM), and others.

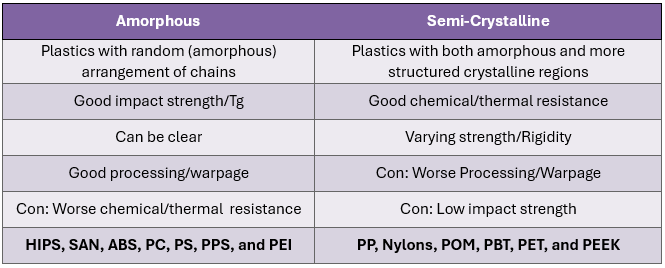

All of these materials are thermoplastics that fit within two broad categories. Amorphous resins (HIPS, SAN, ABS, PC, and others) that have a random (amorphous) arrangement of polymer chains and no crystalline regions. These material types typically have good impact strength, high glass transition temperatures (Tg). They can be clear, are easier to process, and typically have less warpage upon cooling. On the downside, they have worse chemical/thermal resistance. Semi-crystalline resins (PP, nylons, POM, PBT, and others) have amorphous regions alongside crystalline regions. They typically have good chemical, thermal, and environmental resistance with some variations in strength/rigidity. On the downside, they typically have lower impact strength, are more difficult to process, and typically have higher warpage upon cooling. A summary of the typical characteristics associated with amorphous and semi-crystalline materials are shown in Table 1.

All of these materials are thermoplastics that fit within two broad categories. Amorphous resins (HIPS, SAN, ABS, PC, and others) that have a random (amorphous) arrangement of polymer chains and no crystalline regions. These material types typically have good impact strength, high glass transition temperatures (Tg). They can be clear, are easier to process, and typically have less warpage upon cooling. On the downside, they have worse chemical/thermal resistance. Semi-crystalline resins (PP, nylons, POM, PBT, and others) have amorphous regions alongside crystalline regions. They typically have good chemical, thermal, and environmental resistance with some variations in strength/rigidity. On the downside, they typically have lower impact strength, are more difficult to process, and typically have higher warpage upon cooling. A summary of the typical characteristics associated with amorphous and semi-crystalline materials are shown in Table 1.

Table 1. Comparison of typical amorphous versus semi-crystalline characteristics.

The Big Four

Polypropylene (PP)

This semi-crystalline material is valued for its affordability, chemical, moisture and fatigue resistance. It finds diverse applications in appliances, from internal dishwasher components and refrigerator water filters to threaded components and corrugated drain hoses.

The structure of PP is simple, with a backbone of carbon atoms and a methyl group (CH3) attached to every other carbon. Copolymerization with ethylene can be used to improve toughness and there are many fillers (talc) and reinforcements (glass fibers) that can be used to improve other properties. Clarifying agents create tiny, organized crystal structures in polypropylene, resulting in a semi-transparent material known as clarified PP.

- Pros:

- Lightweight and cost-effective.

- Excellent chemical and moisture resistance, making it suitable for applications requiring contact with food or cleaning agents.

- Good fatigue resistance, making it suitable for components that undergo repeated stress.

- Can be tailored for specific applications through copolymerization and the use of fillers and reinforcements.

- Cons:

- Low impact strength.

- Poor cold temperature performance, becoming brittle at lower temperatures.

- Low oxidation resistance in potable water environments (antioxidants are used to prevent degradation).

- Poor creep resistance, making it unsuitable for load-bearing applications at room temperature without reinforcements/fillers.

- High flammability, requiring flame retardants for certain applications.

High Impact Polystyrene (HIPS)

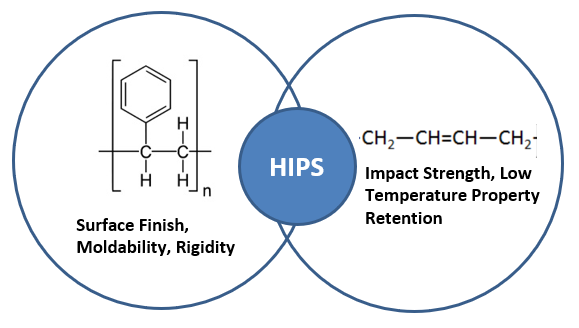

This amorphous plastic is known for its good impact strength, processibility, and cost-effectiveness. This makes it suitable for refrigerator liners, small appliance housings, air conditioner parts, and electronic cabinets like TV cabinets.

This amorphous plastic is known for its good impact strength, processibility, and cost-effectiveness. This makes it suitable for refrigerator liners, small appliance housings, air conditioner parts, and electronic cabinets like TV cabinets.

HIPS is a blend of polystyrene and polybutadiene rubber. The polystyrene component provides stiffness, while the polybutadiene component adds impact resistance. The percentage of butadiene can vary, influencing the material’s impact strength and other mechanical properties.

Pros:

Pros:

- Good impact strength, making it resistant to breakage.

- Excellent processibility, allowing for easy molding into complex shapes.

- Cost-effective, making it an attractive option for various applications.

- Cons:

- Fairly low mechanical properties beyond modulus and impact strength.

- Poor chemical resistance, making it unsuitable for contact with certain solvents and chemicals.

- Prone to weathering, making it unsuitable for outdoor applications without proper stabilization.

Styrene Acrylonitrile (SAN)

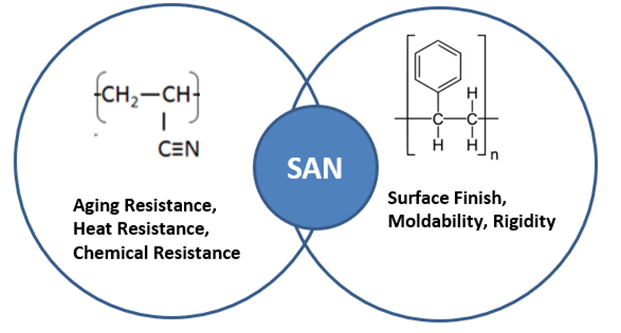

SAN stands out for its exceptional glass-like clarity, rigidity, and thermal properties. It is a preferred choice for clear components like blender bowls, food processor bowls, and windows. It is also used for other rigid components like electric fan propellers.

SAN is an amorphous copolymer of styrene and acrylonitrile. The styrene provides stiffness, and moldability, while the acrylonitrile enhances heat, chemical, and aging resistance. The ratio of styrene to acrylonitrile can be adjusted to fine-tune the material’s properties.

- Pros:

- Exceptional clarity, making it suitable for applications requiring transparency.

- High rigidity and dimensional stability, making it suitable for components requiring precise dimensions.

- Good thermal properties, making it suitable for applications requiring heat resistance.

- Exceptional clarity, making it suitable for applications requiring transparency.

- Cons:

- Brittle and notch sensitive, making it prone to cracking with sharp corners in long-term high, stress applications.

- Low impact strength.

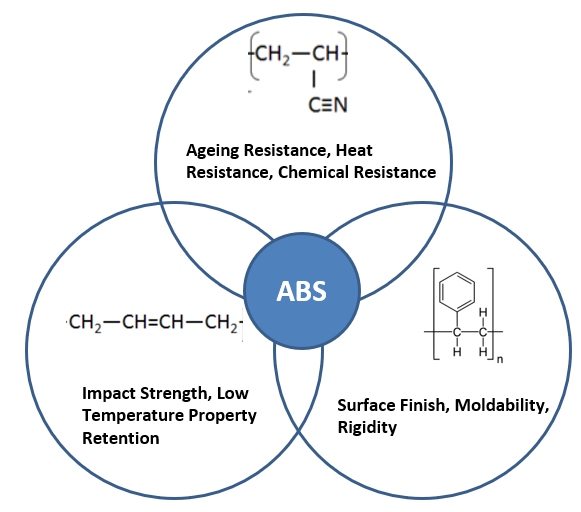

Acrylonitrile Butadiene Styrene (ABS)

This amorphous copolymer offers a good balance of impact strength, processing ease, and dimensional stability, making it suitable for numerous applications including refrigerator door liners, and housings for numerous appliances (hair dryers, curling irons, blenders, vacuum cleaners, coffee makers, etc.).

ABS is a terpolymer composed of acrylonitrile, butadiene, and styrene. Acrylonitrile provides thermal, chemical, and aging resistance, butadiene enhances impact resistance and low-temperature ductility, and styrene contributes to ease of processing and rigidity. The proportions of these components can vary significantly, resulting in a wide range of ABS grades with different property profiles.

- Pros:

- Excellent impact strength, making it resistant to breakage.

- Easy to process and mold into complex shapes.

- Good dimensional stability, making it suitable for components requiring precise dimensions.

- Cons:

- Chemical resistance is okay, but not as strong as semi-crystalline resins.

- Not as cost effective as other polymers mentioned in this article (e.g. HIPS).

- Not intended for outdoor applications due to its susceptibility to UV degradation.

Many More Resins!

There are many more materials commonly used in appliance applications. Some common thermoplastics and there associated attributes are included here:

- Polycarbonate (PC)

- Great mechanical properties

- Great impact strength/toughness

- Transparent and good processing

- Con: Poor chemical resistance

- Polyoxymethylene (Acetal)

- Good dimensions stability/rigid

- Good wear resistance/lubricity

- Good chemical resistance (Not great in chlorinated water)

- Polyamides (Nylon)

- Many different properties across all types

- Good mechanical properties/thermal range

- Good chemical resistance

- Con: Moisture absorption will change properties

- Polybutylene Terephthalate (PBT)

- Good electrical properties/some wear resistance

- Good chemical resistance (Except hot water)

- Con: Dimensional stability/processing

Key Design Considerations

When selecting plastics for appliance applications, several performance requirements need to be considered, including aesthetics, chemical resistance, mechanical properties, and thermal properties.

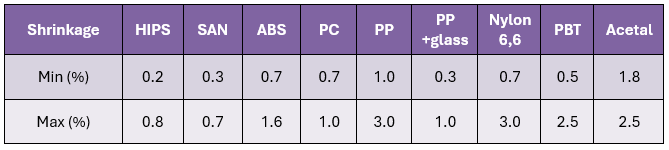

Aesthetics

Clarity, part shrinkage, and surface texture significantly influence the visual appeal of appliance components. Amorphous resins are often the go-to choice for achieving clarity (SAN, PC, and PS are transparent). Part shrinkage must also be carefully managed to avoid residual stresses, sink marks, and warpage. Typical molding shrinkage values for common appliance plastics are provided in Table 2. Surface textures can be achieved through molding techniques to enhance the product’s aesthetics.

Table 2. Typical molding shrinkage percentages for various appliance plastics.

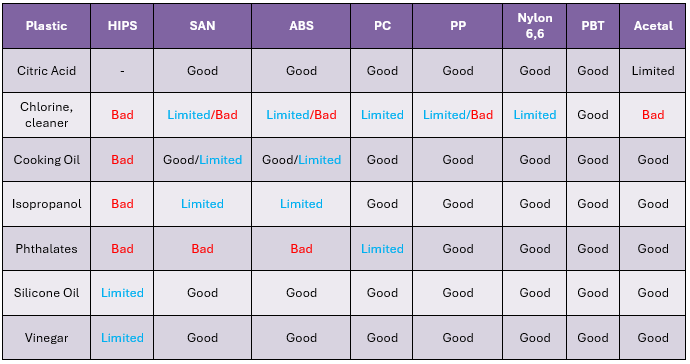

Chemical Resistance

Appliances come into contact with a variety of chemicals, ranging from food substances to cleaning agents. Semi-crystalline resins generally exhibit superior chemical resistance. Table 3 provides a summary of how common appliance plastics react with various chemicals. It is important to remember when reviewing chemical resistance charts like this that plastics can also be susceptible to environmental stress cracking (ESC). This occurs when the plastic component is under stress while simultaneously exposed to chemicals. If available chemical resistance literature does not provide compatibility of the plastic under load this data may need to be generated for the materials and chemicals of interest.

Table 3. General chemical compatibility of common appliance plastics.

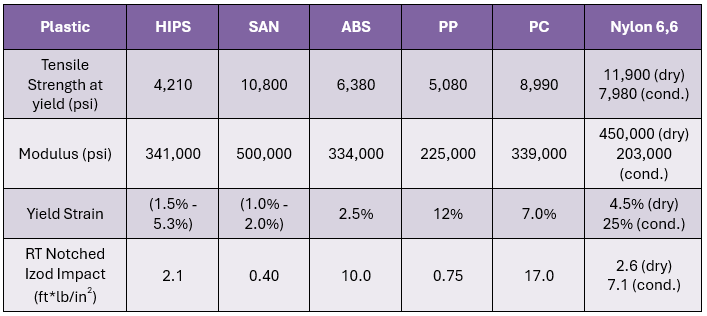

Mechanical Properties

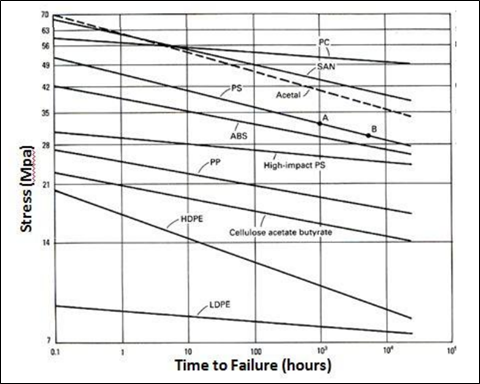

Understanding both the short-term and long-term mechanical behavior of plastics is vital in selecting the appropriate material. While short-term properties like tensile strength, modulus, and impact resistance are important, long-term properties such as creep and fatigue resistance ultimately determine a plastic’s durability. Typical short-term mechanical properties for common appliance plastics are presented in Table 4. Remember that the long-term strength of plastics is always lower than initial datasheet values. This means that to avoid creep and fatigue failure, the stresses and strains experienced in the application must be kept significantly lower. One must also keep in mind that datasheet values are typically tested at room temperature, and do not consider degradation due to chemical, thermal, or other environmental factors. It is best to perform robust product testing to ensure long-term success of the material in application. Short-term property product testing might include impact testing at different heights and impact points on a handheld appliance. For fatigue resistance, cyclical product testing can be performed (e.g. running a dishwasher for X number of cycles until failure). Creep testing proves more difficult as long testing times can prohibit direct testing. Creep evaluations of materials can be performed to calculate time to failure at different static stresses as shown in Figure 1. This can be compared to static stresses calculated from finite element analysis (FEA) to determine if the material even has the chance to last for the expected product life.

Table 4. Short-term mechanical properties of common appliance plastics.

Figure 1. Time to failure under certain stress levels for common thermoplastics.

Thermal/Degradation Properties

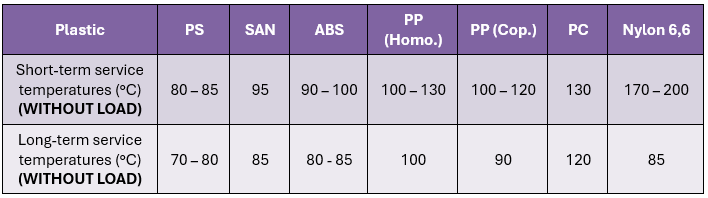

Appliances often operate at high temperatures, making it essential to select plastics with adequate thermal and thermal-oxidative resistance. Many factors contribute to aging and degradation of plastic materials including load, temperatures of use, time at elevated temperatures, chemicals, environmental factors, etc. Therefore, it is always recommended to perform long-term tests on a molded part or test specimens rather than rely on datasheets to design for long-term use. Often a material’s Relative Thermal Index (RTI) is used to select materials for use within an application’s operating temperature range. However, the RTI does not represent a maximum continuous use temperature for the material, but rather the temperature at which a material experiences a 50% loss in a specific property (i.e. strength, impact, and dielectric strength). As a baseline, Table 5 provides general short-term and long-term use temperatures for common appliance materials without load.

Table 5. Short-term and long-term service temperatures of common appliance plastics.

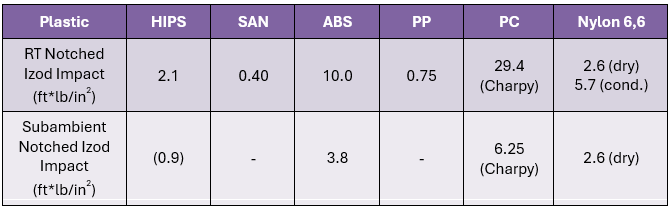

Low-Temperature Performance

For appliances used in cold environments, the plastic’s low temperature impact strength and flexibility are critical. Most materials become more brittle at lower temperatures, making careful selection essential. Table 6 shows how impact properties of plastics change when tested at subambient temperatures compared to room temperature (RT).

Table 6. Impact strengths of common appliance plastics at room temperature and subambient temperatures.

Conclusion

The selection of plastics for appliances is a multifaceted decision with significant implications for product performance, aesthetics, and longevity. By understanding the distinct properties of each plastic type, designers and manufacturers can optimize their choices to meet the specific demands of each application.

From the cost-effectiveness of polypropylene to the clarity of SAN and the balanced performance of ABS, the world of appliance plastics offers a diverse toolkit for innovation. Careful consideration of factors like chemical resistance, mechanical properties, and thermal performance ensures that the chosen material will not only meet immediate needs but also withstand the test of time and use.

As technology advances, we can expect further developments in the field of appliance plastics, leading to even more durable, sustainable, and aesthetically pleasing products. This continuous evolution underscores the importance of staying informed about the latest materials and design considerations to create appliances that seamlessly integrate into our modern lives.

Interested in learning more check out this article:

How Poor Design Decisions Can Lead to Environmental Stress Cracking