This article was originally published in Plastics Technology, September 2023.

Often in manufacturing it is assumed that part rejection, or low yield, is a result of non-conformance to dimensions and excessive warpage. However, many times, and sometimes more often with injection-molded plastic components, parts are rejected due to cosmetic issues. Whether there is a black speck in a transparent part, color or gloss variation from shot-to-shot, once these issues arise there tends to be a lot of finger pointing. Additionally, with the cosmetic aspects of molding still being considered more of an art than a science, the corrective action tends to result in many investigation avenues being identified and pursued. This leads to significant cost and time delays in the project. This article highlights, through case studies, how taking a step back and identifying the root cause of the issue can help focus the direction of those corrective actions.

Where to Start?

In general, the first step in any cosmetic investigation is a robust visual inspection. While this may seem obvious, a thorough visual analysis can provide a wealth of information to both rule out and hone-in on potential cause(s) of defects. A well-run visual investigation may include use of different light sources, examination of physical cross-sections, and use of microscopes. However, in all cases, this initial assessment should include higher magnification investigation, such as optical or scanning electron microscopy, to visualize the defect and allow for proper identification of the issue at play. The goal is to understand the physical characteristics of the defect, the interaction of the defect with the base polymer, and the pervasiveness of the cosmetic issue.

With a true understanding of the physical nature of the defect, the field of investigation should already be narrowed. However, getting to root cause typically requires some form of compositional or analytical testing to help prove or disprove hypotheses formed during the visual assessment. While the correct method is dependent on the specific issue observed, some examples of testing that can help to further pinpoint the issue are Fourier transform infrared spectroscopy (FTIR), Differential scanning calorimetry (DSC), Thermogravimetric analysis (TGA), melt flow rate (MFR), Energy dispersive X-ray spectroscopy (EDS), as well as many others. In many cases, only one or two of these tests is required to greatly reduce the required troubleshooting at the press. With a small amount of data, the investigation can be taken from dozens of avenues in material, molding parameters, mold design, and potential contamination to just a few likely culprits.

To further show how a small amount of data can speed up root cause investigations we will present a few case studies where the above-described analyses helped to identify the cause of the cosmetic issues.

Encapsulated Black Specs

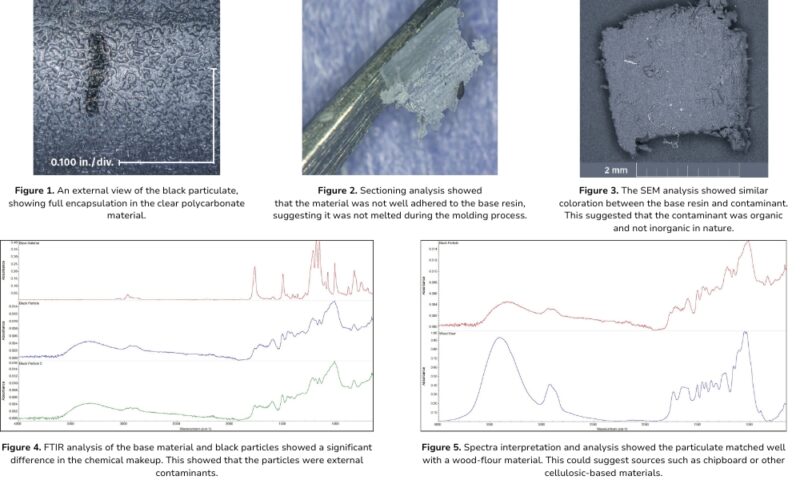

A part was submitted for a visual defect analysis that was manufactured from a polycarbonate material with added colorant or fillers. Visual investigation showed several black particles that were encapsulated in the part wall at multiple locations, Figure 1. The black particle showed clear edges with limited visual indications of melting/flowing during the molding process. Additionally, the cross-sectional analysis showed minimal interaction of the particle with the base resin, Figure 2. Utilizing a scanning electron microscope (SEM) and EDS highlighted that the particle was a single solid material rather than an agglomeration of smaller particulates that was likely organic in nature, Figure 3. In general, these characteristics suggested a polymeric or higher molecular weight material that did not melt at the polycarbonate process temperatures and was not fully miscible with the polycarbonate. This visual analysis rules out sources such as lower molecular weight viscous fluids, inorganic substances, and agglomeration of additives such as carbon black.

To further investigate the chemical make-up of the black particle, the contaminant was removed from the part and analyzed via Fourier transform infrared spectroscopy (FTIR), Figure 4. The top, red spectrum represents the analysis of the part remote from the black particles. The observed peaks were characteristic of a polycarbonate, as expected from the material. Comparison of this spectrum with the spectrum from the extracted particles showed a significantly different chemical make-up for the black particles. Subsequent analysis and interpretation of the black particle spectra showed that the observed peaks were characteristic of a wood flour type substance, Figure 5. This type of chemical identification could suggest the particle was from a chipboard, cardboard, or other cellulosic sources. With this information, the sources of potential contamination on the manufacturing floor were limited to looking for how this type of material could get into the material stream.

Surface Discoloration

Surface Discoloration

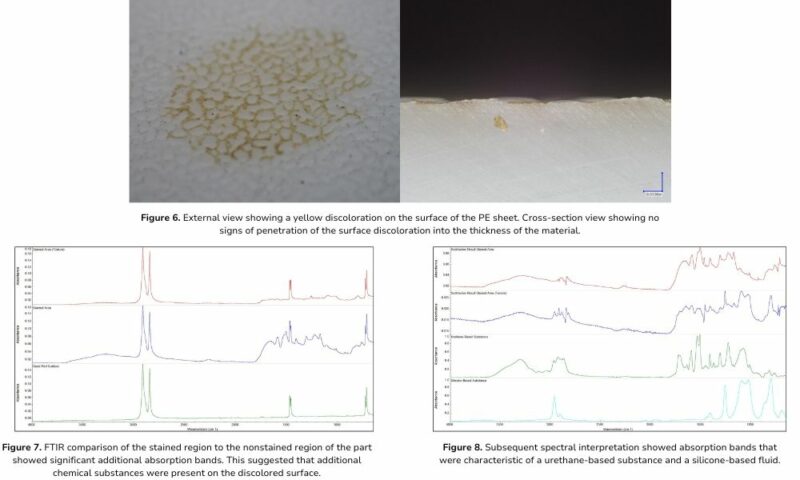

A polyethylene sheet was submitted that showed a yellow discoloration present on the external surface in multiple locations, Figure 6. It was indicated that the parts looked completely normal directly after molding and the defect appeared during storage. Visual investigation revealed that the contamination was mostly present within the valleys of the surface texture. A cross section of the defect region showed that the discoloration was indeed contained to the surface of the component, Figure 7. These observations suggested that the substance was not miscible or chemically attracted to the base material. Based on these visual characteristics, effects such as external contamination or additive blooming effects could result in the observed defect.

FTIR testing was again selected as the analytical technique to investigate the defect region further. The analysis of the base material showed peaks expected of a polyethylene material. However, comparison to the discolored regions of the part showed significant additional peaks that suggested an external contamination and not an additive bloom/agglomeration effect, Figure 8. Subsequent interpretation showed the surface contaminants were consistent with both silicone and urethane-based substances, Figure 9. This matched well with a sealant utilized during the assembly of the parts after molding but prior to storage. Based on the findings of the analytical testing it was determined that exposure to UV light during storage caused the observed yellow discoloration.

Color Variation

Color Variation

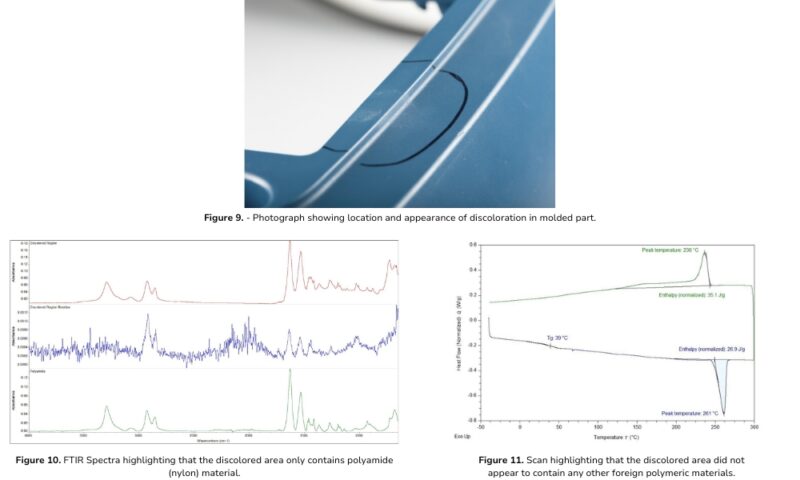

The last case study highlights a component where the customer was having poor color consistency in a molded part. A mold was built and being qualified for production. However, the part was exhibiting poor surface aesthetics along the top edge of the part that was leading to poor part yield. The part was specified as being manufactured from an unfilled polyamide with a flame retardant in it. The material came pre-colored from the material supplier and had been dried prior to molding. The visual inspection revealed that the discoloration was isolated to the areas directly in front of the gates, where the plastic begins to form the part, Figure 9. The area was then investigated by utilizing both FTIR and DSC, Figures 10 and 11. Both revealed that there was no sign of contamination. Finally, the part underwent intrinsic viscosity (IV) testing to determine if the material had been degraded or not. The results of this test again revealed that the material had not experienced bulk degradation during processing.

From the investigation thus far, it was confirmed that the cause of the color variation was not due to contamination, but was inherent to the base polymer. Additionally, the testing revealed that the material did not exhibit any bulk degradation during process. Therefore, the investigation turned to the details of the mold design and processing condition. Given the location of the discoloration, a calculation was performed to determine the shear rate that material experienced when flowing through the gate. The calculation revealed that the shear rates exceeded the recommended limit from the material supplier for cosmetic parts. These excessive shear rates led to some of the lower molecular weight additives in the resin to degrade and produce the poor surface finish. Based on the results of the investigation, it was recommended to increase the gate thickness by just 0.005” to help reduce the shear rates, which allowed for the part to have more consistent color. This simple fix allowed for the mold to be accepted and yield to increase for the part.

Cosmetic issues can often lead to headaches for quality engineers, injection molders and toolmakers. When they arise, it can be stressful as the sources can be numerous, and their presence often leads to large root cause investigations. These investigations can yield many avenues to pursue. However, this article highlights how taking a step back and generating some data regarding the nature of the defects can help fight through intuition and save time and money for all parties involved.