Introduction

In the construction industry, chlorinated poly(vinyl chloride) (CPVC) is commonly used for delivering hot and cold potable water as well as in fire suppression systems. CPVC piping presents numerous benefits over metal piping, making it a prevalent selection during value engineering initiatives. However, the frequency of failures in these systems is on the rise due to a variety of reasons. Unfortunately, when a failure occurs, it often leads to significant water loss. The flowing water can cascade through multiple floors, causing considerable damage in its path. The financial repercussions can escalate significantly if the water seeps down the elevator shaft, damaging the electrical and control systems. This article will examine failures linked to the interaction of CPVC with materials commonly present in the construction industry that are incompatible.

Use of CPVC in the Construction Industry

CPVC shares a connection with poly(vinyl chloride) PVC, as both exhibit a comparable molecular structure. The key divergence lies in the chlorine content, with CPVC containing over 70%, while PVC maintains approximately 57%. Both materials possess an amorphous structure. Within the construction sector, PVC is frequently employed for sewer and venting purposes due to its superior chemical resistance. The additional chlorine in CPVC’s molecular structure imparts heightened strength, modulus, and, notably, superior thermal stability. These enhanced properties make CPVC suitable for applications in hot and cold water supply piping. CPVC pipes find application in various settings, from residential homes to expansive high-rise structures. The construction sector finds CPVC appealing for piping systems within buildings for the conveyance of potable water due to various reasons:

- It is lightweight when compared to both metal and certain plastic alternatives.

- The cost of CPVC pipes is more economical.

- Installation involves solvent cement, offering ease compared to metal and certain plastic alternatives.

- CPVC is corrosion-resistant.

- Lower thermal conductivity, which helps CPVC retain hot and cold water for extended periods of time.

Many fire caulks are incompatible with CPVC.

Issues with CPVC in the Construction Industry

Despite the improvement in mechanical strength and heat resistance provided by CPVC’s molecular structure, a noteworthy decline occurs in its environmental stress cracking (ESC) resistance when exposed to materials commonly used in the construction industry. This creates significant challenges that are often overlooked, resulting in substantial financial losses when this results in product failure. The ESC resistance of CPVC is a crucial aspect to consider in its interaction with common construction industry materials, such as:

- Fire caulks/sealants

- Acoustical sealants

- Duct caulk

- Communication cable (e.g., CAT5/6 cabling)

- Insect and rodent repellents

- Glycol-based antifreezes

- Non-USP glycerin-based antifreezes

- Amine-based antimicrobials

Other challenges with using CPVC piping in the construction industry include:

- Thermal expansion and contraction of CPVC are notably higher than metal alternatives, possibly resulting in increased stresses within the pipes. To mitigate this, loops in the system are commonly implemented, although they are occasionally overlooked.

- The material possesses time-dependent properties that may induce changes in structural integrity over time.

- CPVC can suffer from oxidation, but is orders of magnitude less prone to oxidation than polypropylene (e.g. Aquatherm) piping.

Some specific incompatibility issues involve the following:

Numerous fire caulks, essential for firewall penetrations, do not work well with CPVC piping. These caulks contain a plasticizer that can lead to ESC over an indeterminate period. The timeframe is challenging to define and is influenced by various factors like temperature and stress. Based on experience, failures often begin to manifest between 3 to 7 years post-installation. Examples of fire caulks that are incompatible with CPVC include:

- Hilti CP 606 Flexible Firestop Sealant

- 3M Fire Barrier Sealant FD 150+

- 3M Fire Barrier CP 25WB+

Likewise, there are numerous acoustical sealants that are also incompatible with CVPC piping:

- Hilti CP 506 Smoke and Acoustical Sealant

- United States Gypsum (USG) Firecode Smoke-Sound Sealant

Communication cables share the same ceiling space as the CPVC piping and are commonly draped on the CPVC piping. These cables commonly have a plastic jacket that contains a plasticizer that is incompatible with CPVC piping. Over time the plasticizer has the potential to migrate into the CPVC and cause ESC. CPVC pipe manufacturers have been aware of this for years and have provided warnings printed on the outside of the pipe, as well as in their installation manuals. At times the communication cable will leave a mark on the pipe, while at other times there is little, if any, marking created. The absence of visible markings does not necessarily imply that the plasticizer has not migrated into the pipe.

There are many communication cables that share the same ceiling space as CPVC piping. Communication cables are not supposed to come in contact with CPVC piping. When these cables come into contact with CPVC they can leave visible marks.

Determining Incompatibility with CPVC

Test methods exist to identify foreign materials that come into contact with CPVC piping. Ensuring accurate identification requires the expertise of an engineer or laboratory technician familiar with these materials, along with well-maintained instrumentation and access to the appropriate spectral libraries.

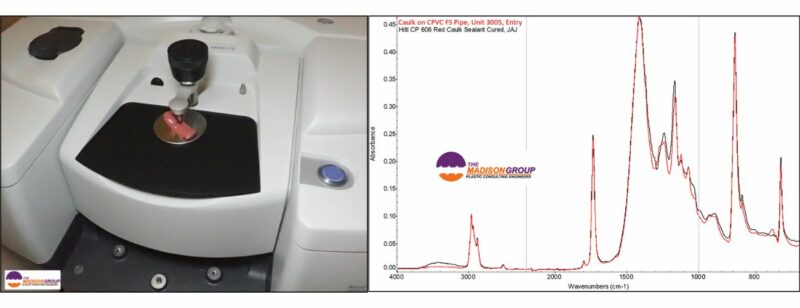

Fourier transform infrared spectroscopy was used to identify a caulk removed from a CPVC fire suppression pipe. The FTIR spectrum obtained demonstrated a library match to Hilti CP 506.

Given that the manifestation of a failure does not pinpoint the singular location where incompatible materials have been applied to the CPVC piping, but rather signifies the initiation of potential additional failures, there’s a possibility that the issue is systemic throughout the building. Predicting the specific locations where these incompatible materials were used is challenging, if not impossible. Therefore, it becomes necessary to take a large sampling population and/or replace all CPVC piping that are in contact with a caulk. While the cost and inconvenience of such a widespread replacement can be substantial, it is considerably less than the alternative of taking no action and awaiting the inevitable appearance of leaks.

CPVC Piping Can Function Effectively For Years

While CPVC presents an appealing alternative to metal and other plastic products, offering numerous benefits, caution is necessary to prevent its contact with common incompatible materials in the construction industry. Ensuring the correct installation procedures and operating conditions are observed, and avoiding contact with incompatible materials, increases the likelihood that CPVC piping will perform adequately throughout its expected product lifespan.

The Madison Group possesses the knowledge and proficiency to assess plastic piping systems in structures ranging from small to high-rise buildings. As the plastics experts, we can assist in identifying the causes and mechanisms behind the failure of a plastic piping system or its exposure to conditions that could potentially result in failure.