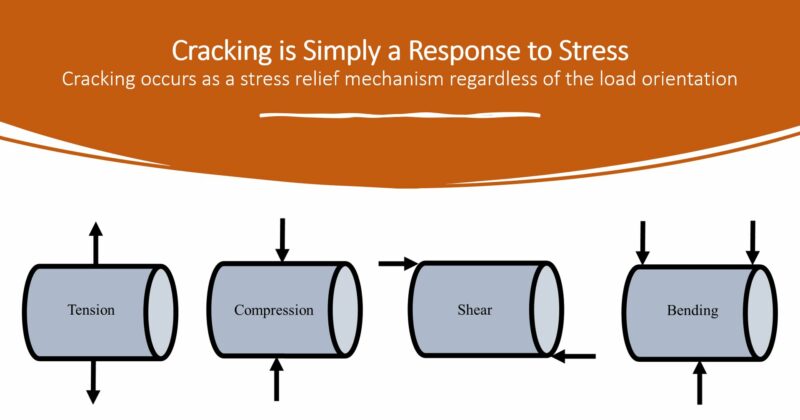

Why Cracking is Simply a Response to Stress

At its core, every crack tells a story. When a component fails, it isn’t just breaking; it is undergoing stress-induced cracking. Regardless of the material, a crack indicates that the localized stress levels exceeded the material’s strength over a specific timeframe and under specific environmental or loading conditions.

Essentially, stress-induced cracking is a mechanical response. The part is attempting to find equilibrium by dissipating energy that it can no longer support. This holds true across a variety of scenarios:

- Internal vs. External: Whether the stress is molded-in (residual) or applied by an outside force.

- Static vs. Dynamic: Whether the load is constant, intermittent, or cyclic (fatigue).

- Loading Mode: Whether the material is reacting to tension, compression, shear, or bending.

The Power of Fractography in Failure Analysis

To solve a failure, we must look beyond the fact that a part broke and ask why and how it happened. This is where fractography—the microscopic examination of fracture surfaces—becomes indispensable.

By analyzing the fracture at various magnifications, we can decode the specific stress-induced cracking mechanism at play. Fractography provides data on:

- Failure Mode: Was it brittle, ductile, or environmental?

- Stress Magnitude: How much force was involved?

- Directionality: From which point did the crack originate, and where did it travel?

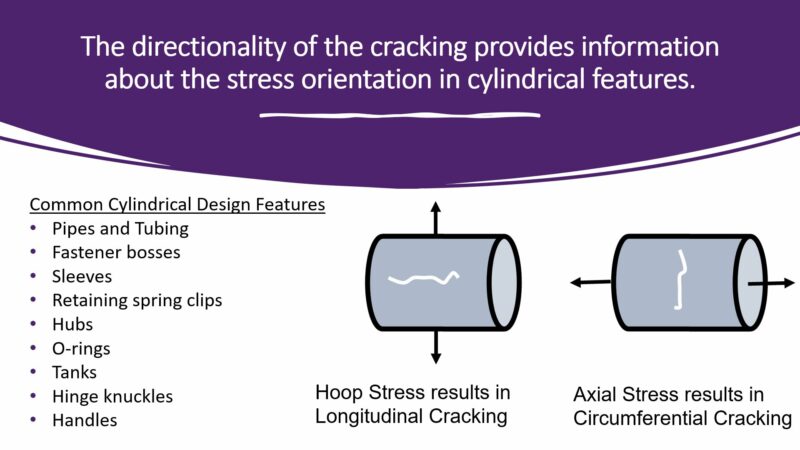

Stress-Induced Cracking in Cylindrical Features

Cylindrical designs—such as pipes, fastener bosses, tanks, and O-rings—are common in engineering, but they are also prone to specific stress profiles. Through fractography, we can determine the orientation of the stress-induced cracking:

- Axial Stress: Results in circumferential (transverse) cracking.

- Hoop Stress: Results in longitudinal cracking.

Identifying these patterns is the first step toward optimizing a design or selecting a more suitable material.

Conclusion

Never underestimate the value of a detailed fractographic examination. With the right mix of materials knowledge and mechanical insight, analyzing the stress-induced cracking provides the clarity needed to prevent future failures and ensure long-term product reliability. Learn more about Fractography of a Polyacetal Cylinder.