This paper was originally published and presented at The Society of Plastics Engineers’ ANTEC in 2010

Failures occurred within medical housing assemblies. The cracking was observed in a significant number of parts that had been in service, and was found within the hinge bosses used on the various components of the assembly. The focus of this investigation was a determination of the nature and cause of the failures. The results obtained during the evaluation of the cracked components indicated that the failures occurred through slow crack initiation via fatigue and creep rupture mechanisms. This paper will review the testing performed to characterize the failure mode and identify the cause of the cracking, while demonstrating the analytical procedures used in the investigation.

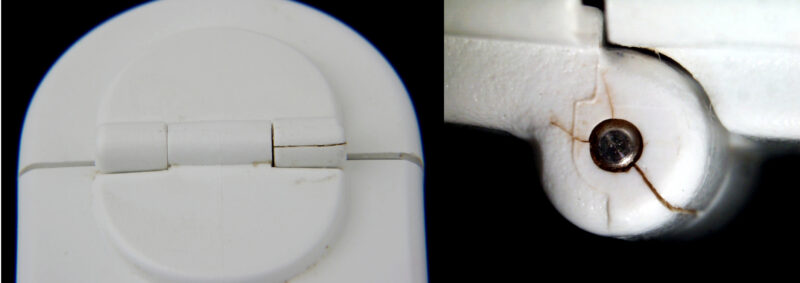

Cracking was apparent within the housing hinge bosses. The crack features were characteristic of brittle fracture.

The housing assemblies were used in a medical application and the failures occurred within the hinges that secured the door and latch components to the main case body. Additionally, failures had also been reported within the corner of the latch component. All of the components were injection molded from Makroblend EL-700, a polycarbonate/poly(ethylene terephthalate) (PC+PET) blend. The door and latch components were stated to have been molded using a family tool, with a separate molding operation used to produce the case. The housings were designed using an interference fit between the hinge pin and the hinge holes. Specifically, a 0.0495 inch hinge pin was used in conjunction with a 0.0480 inch diameter hole. In addition to the failed components, control parts and molding resin were also evaluated for reference purposes.

A failure analysis was performed to identify the nature and cause of the housing assembly failures. This evaluation included:

- Visual and microscopic examinations

- Scanning electron microscopy (SEM)

- Fourier transform infrared spectroscopy (FTIR)

- Differential scanning calorimetry (DSC)

- Thermogravimetric analysis (TGA)

- Energy dispersive X-ray spectroscopy (EDS)

- Thermomechanical analysis (TMA)

- Melt flow rate (MFR)

It was the conclusion of the investigation that the cracking and failures observed within the housing assembly hinges occurred through two primary mechanisms. The visual, microscopic, and SEM examinations indicated that the cracking initiated within the hinge bosses through low cycle fatigue, and through the exertion of relatively low stresses below the yield points over an extended period of time via a creep mechanism. In both the fatigue fracture and the creep ruptures, the crack initiation step appeared to take place relatively slowly, as indicated by the observed fracture features. In both mechanisms, the stresses thought to be responsible for the failure are associated with the interference between the hinge pin and the hinge boss.

This paper will review that failure analysis.