Figure 1 – Diagram showing the levels of characterization and the frequency that the analysis level is utilized in a material characterization.

In the second part of this series, we explored the second tier of material characterization. At this level, a designer will have a much better chance of selecting a material based on data sheet values for their application. The second tier of material characterization is even more important now with the higher level of polymer supply issues making alternative material selection an all-to-familiar issue in the industry. However, this level of characterization will miss several important pieces of data on the additives utilized to modify the properties of the material for exposure conditions. At the second tier, we will not understand if an unknown material has antioxidant additives for stability (e.g., hindered phenols for processing), flame-retardant additives, or UV stabilizers to allow for better long-term performance of the parts. This is where we need additional tests from a Tier III characterization to help us understand the additives that will be of great importance to the performance of the part in the expected environment.

Tier III of material characterization is typically reserved for detailed characterizations of the lower concentration additives that shape the special properties of a material. These additives are typically under 1% by weight within the material and are incorporated into the resin to ensure proper performance over the lifetime of the part. These additives would include antioxidants (to help with processing stability and environmental exposure), slip agents for molding, tackifiers for rubber materials, compatibilizers for blends, flame-retardant additives, and many others. Typically, this level of characterization is employed by designers to reverse engineer materials, resin suppliers, or in cases where part failure has occurred prematurely due to some environmental conditions.

The primary techniques utilized in a Tier III characterization could include mass spectroscopic techniques (GC/MS, LC/MS, HPLC), trace elemental analyses (XRF and ICP), nuclear magnetic resonance spectroscopy (NMR), and gel permeation chromatography (GPC). This is certainly not a comprehensive list of all the higher-level techniques that are utilized to understand the additives in the material. Other techniques can be utilized to meet regulatory standards (RoHS, USP VI, etc.). These tests should be discussed on a project-to-project basis. However, these are the “workhorses” of identifying additives that are commonly used in polymer applications.

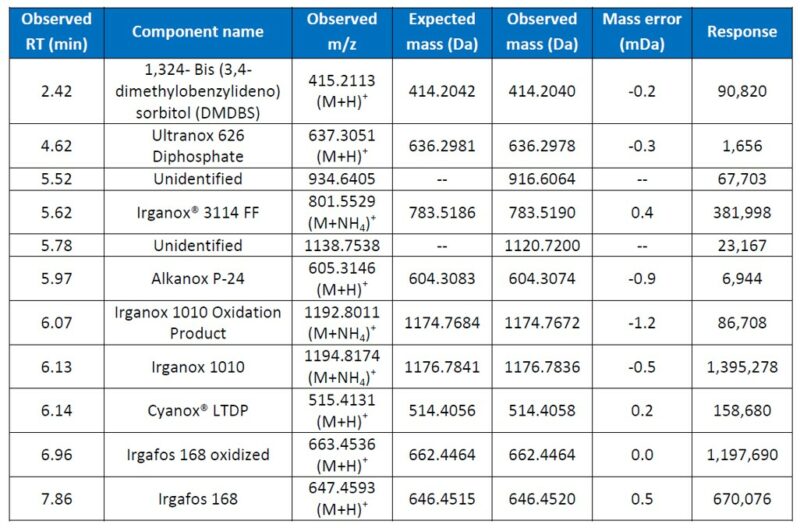

The mass spectroscopy techniques are utilized to look at antioxidants, flow aids, tackifiers, and other lower molecular weight substances. This technique provides a spectrum that is used for identification of chemical compounds at very low (PPM) concentration. Shown in Table 1 are typical results you can expect from this type of analysis. The analysis provides a list of chemical compounds that were in the detectible range of molecular weights for each technique. If you are just running the sample, this is typically just a qualitative identification with limited ability to quantify the amounts of the additives. Quantification is possible with a calibration experiment to a known reference of the additives identified in the material. However, practical designers will rely on material suppliers to determine the correct amount of lower-level additives in a material and testing on the back-end to determine if enough additives are present for the expected exposure and lifetime needs.

Table 1 – Table of results from an LC/MS test of a thermoplastic elastomer. The results show that the material had a stabilizer package with multiple different antioxidants.

Two of the most popular techniques for identifying and quantifying the elemental make-up of a material are ICP and XRF. In the context of a Tier III characterization, these techniques are typically utilized to help with identification of some flame retardants and stabilizers. For example, the use of ICP and XRF can help to identify if a copper iodide stabilizer is being utilized in a polyamide material.

Nuclear magnetic resonance spectroscopy (NMR) is a technique that is basically an FTIR test on steroids. While FTIR is useful to tell what type of bonds are in a material, NMR can construct the backbone structure and determine where in the polymer backbone, those bonds are located. This makes NMR a powerful technique to deconstruct complex molecules such as thermoplastic urethane elastomers and other thermoplastic elastomeric materials. Additionally, it can provide information on polymer blends and branching, which can be extremely important to polymer performance. It should be noted that a deeper level of knowledge of molecular structure is required to properly interpret these results.

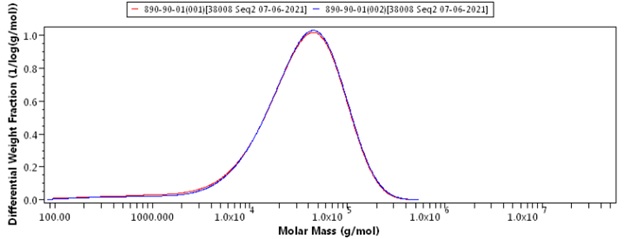

GPC testing is utilized to provide an exact measurement of the molecular weight of a material, including information on the distribution of polymer chain lengths, Figure 2. In a Tier III analysis, GPC analysis would be used to identify more performance-based metrics of molecular weight. Specifically, this method is useful to compare the molecular weight distribution, which will affect the processability and mechanical performance of a polymeric material. In general, this technique is best applied as a comparative analysis between two materials, as there is little published data on exact molecular weights of commercial polymers. However, if you need to investigate the molecular weight curve due to concerns about performance, GPC can be used over MFR to investigate the material.

Figure 2 – Molecular weight curves for two materials that showed minimal difference in molecular weight and molecular weight distribution. In a material characterization setting, these results would show that these materials are similar in molecular weight and would be expected to have similar properties, all else being equal.

While these are certainly not all the techniques that can be used to identify polymeric materials, these techniques are definitely the most utilized techniques in material characterization. The next time you have a question of what material is or should be used within a product, take a minute to think about how involved your analysis needs to be. Whether you need a lower-level identification or a complete material deformulation, there are techniques that can help you move your project forward. The Madison Group has significant experience with all levels of material characterization and would be happy to assist you with all your testing needs.

Check out Polymer Material Characterization Tier 1 and Tier 2.