Even the most advanced materials cannot compensate for fundamental design errors. A recent failure analysis conducted by The Madison Group on an injection-molded switch button illustrates this perfectly. Despite being molded from a high-performance, 20% glass-fiber-reinforced polyphthalamide (PPA)—a material well-suited for the application’s thermal and mechanical demands—the parts were experiencing catastrophic field failures.

Catastrophic cracking had been observed within a retaining post on the switch, rendering the switch and the entire assembly inoperable. The switch was injection molded from a 20% glass fiber reinforced, toughened, heat stabilized polyphthalamide (PPA). This material appeared to be a good choice given the application requirements.

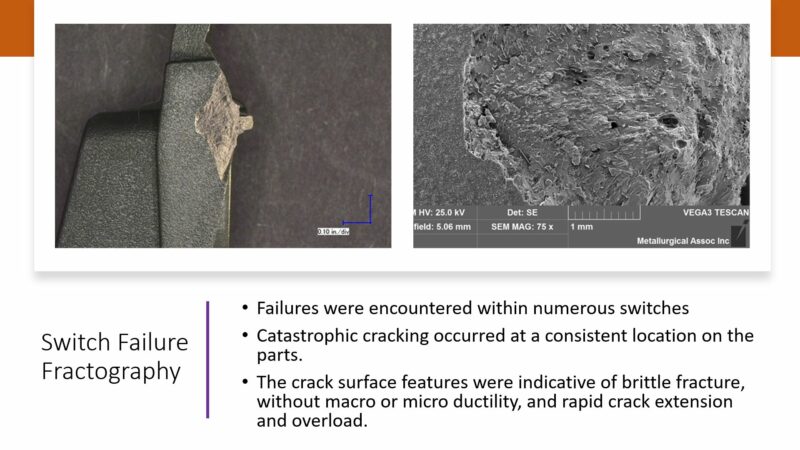

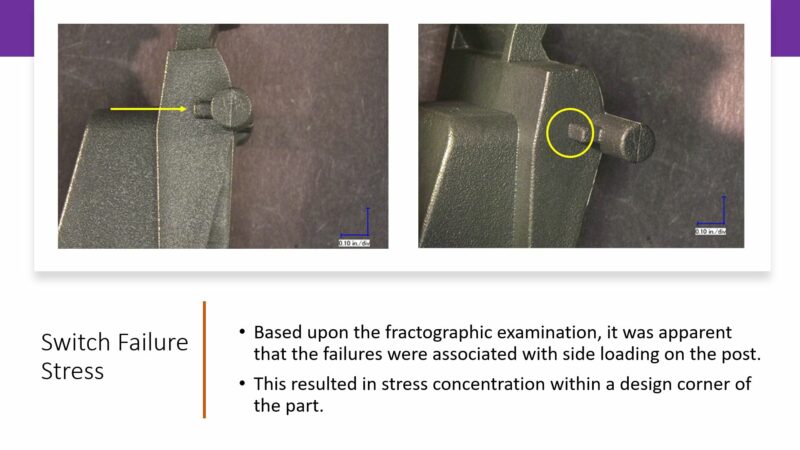

A fractographic examination was performed on several of the returned failed components, revealing consistent features on all the parts. The failures occurred through brittle fracture mechanical overload, in which the applied stresses exceeded the short-term strength of the material.

The features were consistent with the application of bending loads. Cracking initiated within a corner formed by the retaining post boss feature and the main body of the switch.

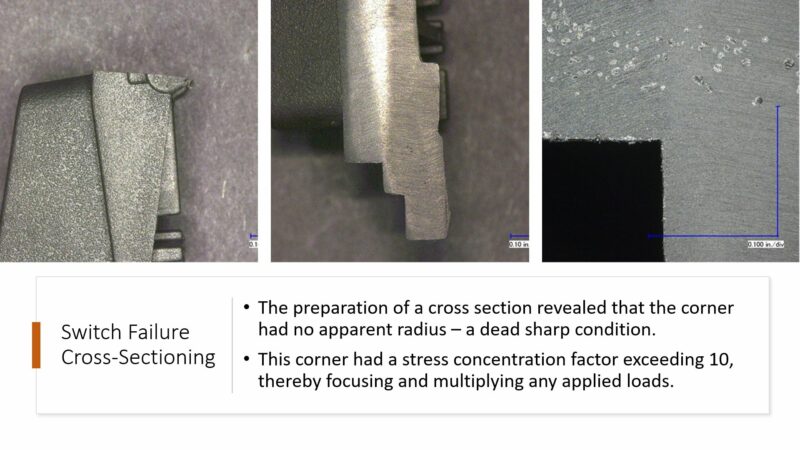

Cross-sectional examination revealed that the failure occurred at a “dead-sharp” internal corner where the retaining post met the main body of the switch. By failing to include a functional radius at this high-stress junction, the design created a stress concentration factor exceeding 10. Essentially, the geometry multiplied the applied loads until they surpassed the material’s short-term strength, leading to mechanical overload.

No evidence was found through the failure analysis to indicate material anomalies, or deficiencies in the injection molding process. This case serves as a critical reminder: superior manufacturing and high-grade resins are secondary to sound geometric design. To ensure part longevity, engineers must prioritize stress distribution and utilize proven design resources to avoid the “sharp corner” trap.

Unfortunately, this is not a rare instance, where poor design mitigates good material selection and excellent manufacturing processes. Every year The Madison Group sees numerous instances of inadequate plastic part design. Plastic part design is critical in producing a component that will perform successfully. Why wait for influx of field failures to find a flaw? The Madison Group can apply forensic insights to your DFM process to catch ‘geometry traps’ before the tool steel is ever cut. By integrating years of failure analysis into your initial design, we can often triple your part’s durability with a single pre-production tweak.