PVC boasts impressive performance characteristics, making it a go-to material for countless applications. However, like any polymer, it has inherent limitations. Failing to properly understand and account for these can easily lead to premature PVC failure.

In previous articles (Parts 1 and 2), we explored the fundamentals of PVC material and its processing characteristics. Today, we delve into real-world examples of typical PVC failure modes.

Temperature Limits and PVC Failure

A well-known limitation of PVC for many applications is its temperature resistance. Rigid PVC has a glass transition temperature (Tg) of 80°C. This means that, as an amorphous material, it will rapidly soften when this temperature is exceeded. Even approaching the Tg can be critical and lead to PVC failure.

Consider an example prevalent in hotter southern states: houses with highly reflective window glass designed to keep interiors cool. While effective for insulation, the reflection can create unexpected heat build-up against vinyl siding on a neighboring house. This concentrated heat can cause the siding to soften, warp, and ultimately result in PVC failure.

UV Radiation and Environmental PVC Failure

For outdoor applications, such as the one just mentioned, other factors like UV-radiation can also adversely affect certain grades of PVC, contributing to PVC failure. Even indoors, UV exposure from fluorescent lamps has been shown to impact some PVC formulations.

Typically, lower UV exposure causes surface aging, leading to discoloration or yellowing. While mechanical properties might not always be immediately compromised, excessive color changes can be deemed unacceptable and signify a PVC failure for the application. This yellowing is attributed to the formation of conjugated double bonds as the molecules break down. Severe, continuous UV exposure, however, can penetrate deeper, causing excessive chain scission and material embrittlement, a significant form of PVC failure. Additionally, chalking can occur as the material degrades and fillers come to the surface.

Figure 1 – View of a fractured PVC bottle that failed in a brittle behavior due to material embrittlement from UV exposure and limited temperature rises.

As discussed in Part I, the performance of a given PVC grade is directly dependent on its unique formulation. For instance, impact-modified transparent rigid PVC is known to be significantly susceptible to UV exposure, making it prone to PVC failure in outdoor settings. Specific pigments, thermal stabilizers, fillers, and UV absorbers can help mitigate the effects of UV aging. Most of these protect PVC by preventing the formation of conjugated double bonds, possessing anti-oxidative properties, and absorbing UV (essentially sacrificing themselves for the polymer). Common UV absorbers used with PVC include benzophenone and benzotriazole. Titanium Dioxide (white) pigment also aids in UV resistance as an excellent UV-absorber. Darker fillers like carbon black also absorb UV effectively, even considering the expected temperature rise with a darker material.

Figure 1 demonstrates a PVC failure where a bottle containing a citric-based cleaner became brittle after sitting on a garage shelf for approximately three years. Despite PVC’s known good chemical resistance to citric acid, the long-term exposure to UV and slight temperature increases led to degradation and a fracture at the bottle’s base – a clear instance of PVC failure.

Additives used to limit thermal degradation during processing can also help prevent environmental degradation, including UV-induced PVC failure. Ultimately, both thermal and UV mechanisms lead to molecular breakdown and the formation of conjugated double bonds. The overall concentration and types of additives used, therefore, significantly impact long-term part performance. Improper additives, insufficient stabilization, or consumption of stabilizers due to aggressive processing conditions can all adversely affect the long-term performance of a part exposed to UV and other environmental factors, increasing the likelihood of PVC failure. Whether due to processing, aggressive UV effects, or long-term aging, as PVC degrades, it becomes increasingly brittle, evident by a significant loss of impact resistance, signaling impending PVC failure.

Environmental testing methods are available to quantitatively assess plastics’ performance against UV-radiation and outdoor environments. This serves as a preventive and comparative measure. For example, a Q-UV (sunlight, rain, and dew) chamber is an accelerated weather tester where plastic sheets are exposed to aggressive UV-radiation, humidity, and outdoor temperature cycles. Performing this accelerated weather test followed by impact testing of the samples can help determine the relative performance of different materials, preventing costly PVC failure down the line. Such preventive and comparative testing provides valuable insight into selecting the best material among several comparably priced options.

Chemical Incompatibility and Environmental Stress Cracking: Causes of PVC Failure

Similar to UV, environmental effects from incompatible chemicals can also result in material embrittlement and PVC failure. Moist chlorine gas, especially at elevated temperatures, can rapidly degrade PVC. This type of PVC failure manifests as severe surface mud-cracking and a loss of material properties. The micro-cracks formed on the surface create stress concentration regions, making them susceptible to further cracking under stress.

Esters and ethers, on the other hand, have affinity with the PVC material and rather than degrading the material result in cracks because of a lubrication effect at the molecular level. With a high enough concentration of chemical and stress, the chemical is absorbed by the polymer and reduces the inter-molecular forces that hold the polymeric molecules together. The localized absorption results in a localized softening effect, molecular disentanglement, and a slow-crack growth mode of PVC failure. This phenomenon is commonly known as environmental stress cracking (ESC). With ESC, the cracks show a smooth morphology characterized by the localized surface modification. Micro-cracks grow stepwise, and chemical modification of the crack tip at every step-crack progression can typically be observed through microscopic analysis of the fracture, providing evidence of PVC failure.

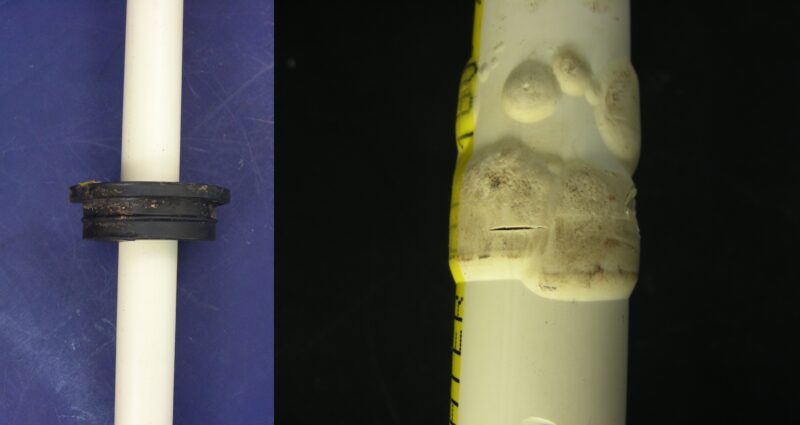

Figure 2 – Failure of a CPVC pipe due to absorption of a phthalate plasticizer from a gasket.

Certain chemicals, such as phthalates, have an even higher affinity with PVC and can be absorbed by the polymer to the point of causing a macro-softening effect. Phthalates are, in fact, common additives used in PVC to create plasticized PVC tubes, which are soft and flexible due to their plasticizing effect. Plasticizers interact with the polymer’s molecular forces, reducing them without solvating the polymer. Therefore, if phthalates contact rigid PVC parts, such as piping, it can lead to devastating PVC failure. An example of PVC failure due to plasticizer migration into piping systems is shown in Figure 2. Here, the piping system is CPVC, not PVC, but both perform similarly when exposed to phthalates. In this example, a rubber gasket used on CPVC piping allowed phthalates to migrate from the rubber to the pipe, leading to softening and rupture – a clear instance of PVC failure. A more in-depth discussion of this failure is discussed in the white paper Proset Rubber Gasket Failure .

There are several methods that can be used as failure prevention measures during design stages to verify any incompatibilities of the material with substances that it may come in contact with. One example is a test that we commonly perform on many polymers including PVC which provides a relative measure of environmental stress cracking resistance (ASTM D 543). These types of tests are very beneficial because plastics like PVC are formulated and compounded using many different additives which can greatly affect chemical compatibility. Thus, one PVC grade might be affected by a given chemical, while another may not, directly impacting the potential for PVC failure. For example, Freon 11 (trichlorofluoromethane) is a chemical known to be incompatible specifically with impact modified PVC grades.

Figure 3 – View of a PVC pipe that failed without ever being in service.

Poor Fusion and Manufacturing-Related PVC Failure

Another phenomenon that can result in PVC failure, particularly observed with larger PVC parts like large PVC piping, is poor fusion, which is directly related to suboptimal processing conditions. A more detailed explanation of this topic was presented in Part 2 of this series. Poor fusion is typically observed in larger parts because they are more challenging to process effectively. Proper PVC processing requires sufficient shear and heat to effectively melt and fuse the PVC particulates inherent to the polymerization process. However, excessive shear can degrade the plastic.

Figure 3 illustrates a large pipe used for underground water transport applications. These extruded pipes have thick walls, making processing more difficult. The pipe shown here cracked without ever being in service. This PVC failure resulted from a combination of internal residual stresses from manufacturing and severely poor fusion. A thorough review of the process combined with testing the pipes for proper fusion and mechanical performance could have prevented such PVC failure. Testing methods such as the ASTM D 2152 acetone immersion test (AT) and ISO 9852 dichloromethane test (DCMT) are qualitative tests that can be performed to evaluate PVC fusion. Additionally, ISO 18373-2, a more quantitative technique using DSC to evaluate the degree of PVC material fusion, has proven extremely valuable in many of our PVC failure analysis investigations.

Categorizing PVC Failure for Comprehensive Understanding

As with other plastics, numerous reasons can cause PVC failure. Due to time constraints, this article has focused on providing quick examples of several common PVC failure modes we observe. However, it’s crucial to remember that failures can be subdivided into five basic categories: material, design, manufacturing, environment, and end use. To this point, we have briefly covered three of these categories.

Design and end use are both extremely important and may be covered as individual future articles focusing on specific types of PVC failure. Typical design-related PVC failure for PVC parts generally relates to high stress concentrations due to sharp geometric transitions, as well as high stresses from snap-fit assemblies. Additionally, problems arising from improper mold and/or gate runner designs are sometimes observed, leading to PVC failure.

End-use PVC failure refers to abuse during use or installation issues. These types of failures are also common and are typically the result of a lack of understanding of plastics’ behavior under stress. A large percentage of the end-use PVC failure we observe show modes of failure related to creep rupture. A proper understanding of the design and stress limitations for the material can typically prevent these modes of PVC failure. Furthermore, for stress-related PVC failure, testing techniques are available that can provide insight into the short and long-term mechanical performance of the material.

See our other installments in this series on PVC: