Nylon, also known as polyamide (PA), resins are a diverse group of materials. The versatility of polyamides make this family of polymers one of the most widely used thermoplastics. Could Wallace Carothers ever have anticipated the significance of his material invention?

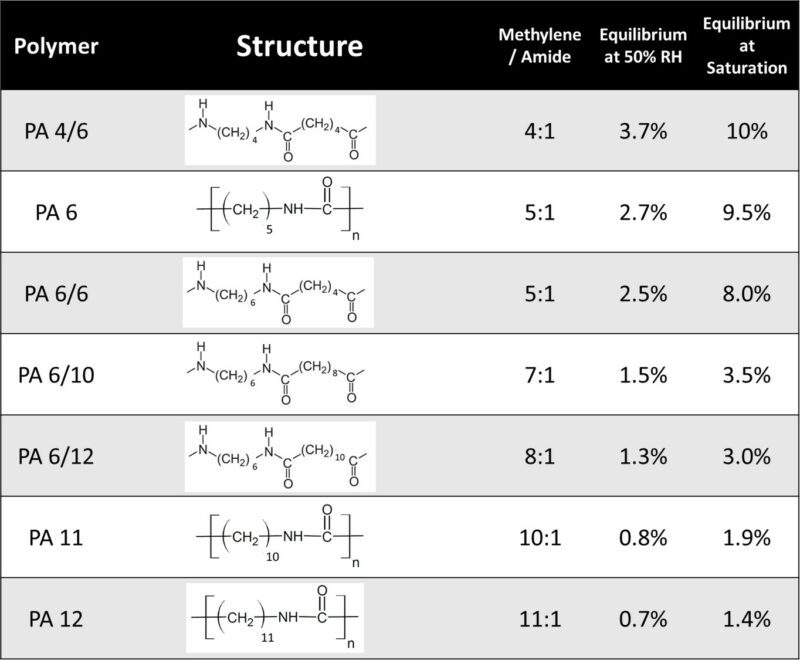

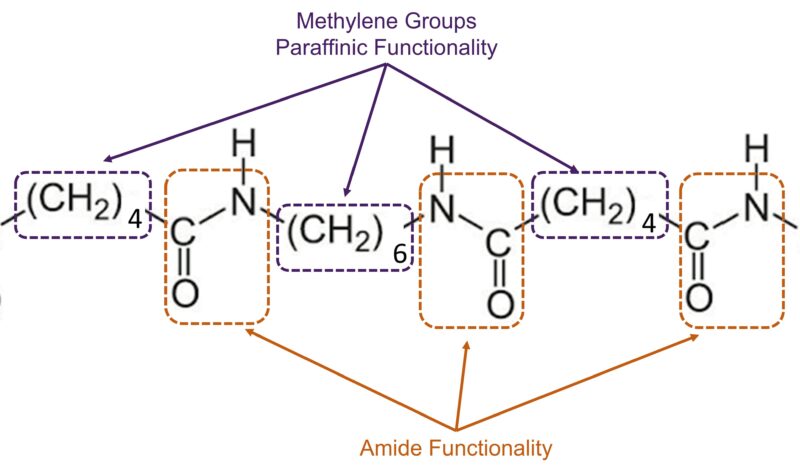

The molecular architecture, and especially the ratio of carbon atoms to amide functionality, is what gives each different type of polyamide structure is unique property characteristics.

This structural relationship affects all the properties of the material, including:

- Mechanical properties

- Thermal characteristics

- Degradation resistance

- Water absorption

Water absorption is an extremely important metric for polyamide materials, since the fundamental properties, such as tensile strength, modulus, impact resistance, and the glass transition temperature, of these materials are different at varying levels of water absorption. The level of water absorption within aliphatic polyamides is directly related to the ratio of paraffinic (methylene) content to amide functionality. The higher the relative proportion of paraffinic structure, the less the water absorption, which in turn results in a lower level of property alteration.

Once again, the properties of plastic materials are directly related to the molecular structure of the polymer.